Moving forward with the handlebar group and the attendant cables/wires. MFH has included all - very complete indeed.

Here is the friction steering damper-

On the right handle bar can be seen the front brake lever, throttle twist grip, air slide lever ( choke ) and horn button - MFH include the wiring for horn button on right and dip switch on left.

On left handlebar can be seen clutch lever , manual ignition advance/retard lever , valve lifter

( compression release ) and dip switch.

For the gear heads amongst us some details .

Bikes of this era and up through the 50’s did not have auto advance for the ignition timing . The long lever you see atop the bars by the clutch lever rotates a face cam in the magneto that opens/closes the points. Unlike what most of us are used to seeing, the cam is stationary ( except for the few degrees of manual rotation by the advance / retard lever ) and the points rotate. Ignition timing is generally set on machines of this era by piston travel rather than degrees of rotation - i.e. on my Norton (IIRC ) the points open at something like 5/8” BTDC on the compression stroke . The magneto shaft is tapered and keyless and driven by a chain from a cog on the intake cam. The mag sprocket is set loose on the shaft and the piston is brought to the proper position. A slip of the thinnest paper ( cigarette paper is the traditional choice) is placed between the points and the shaft is rotated until the points just start to release the paper. At this juncture the the mag sprocket is driven home on the shaft with a tube or socket around the retaining nut and a hammer, then the nut is snugged up . A little further along in this post will be pictures of the points and face cam.

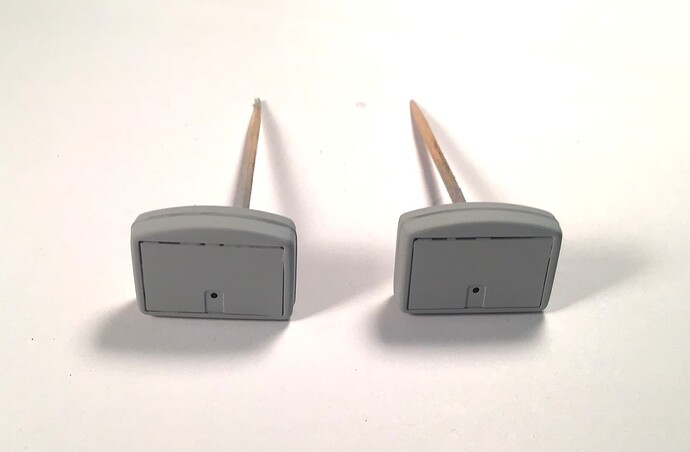

Here is Lucas Altette horn , including wiring . Front view in above picture.

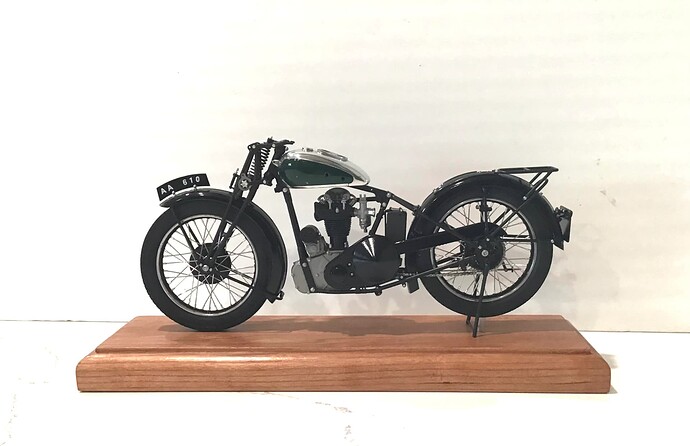

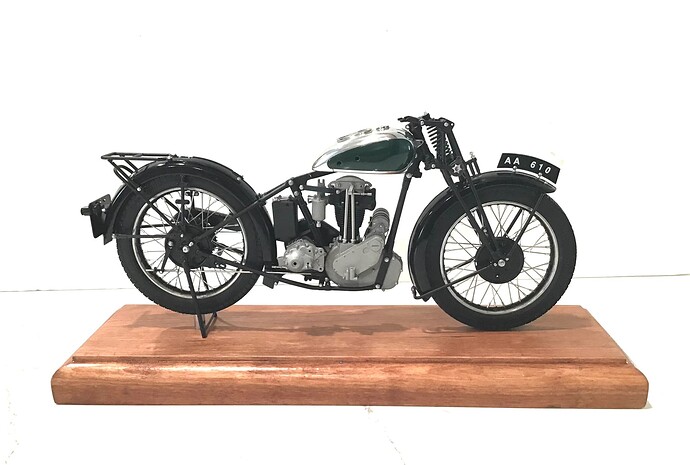

The model …

… and the real thing…

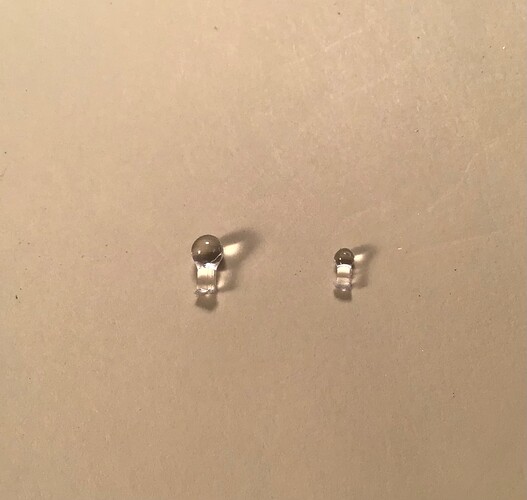

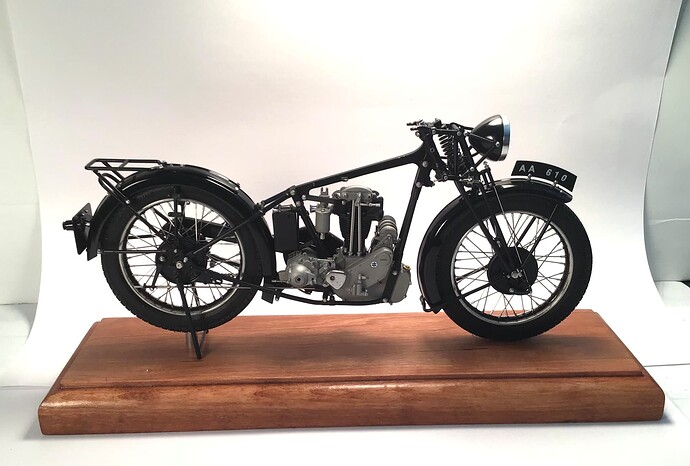

Here is the model Magdyno - magneto on bottom and dyno ( generator) on top , complete with wiring.

Note the points cover and it’s spring retaining bale - just like the real deal .The dyno / battery only provided current for lighting and horn - ignition provided for solely by the magneto. Dynamos of this era were three brush and did not require a voltage regulator - they were problematic and later units , including the actual one you see on my Norton were two brush with regulator.

The real thing - in second pic can be seen the rotating points and their face cam …

Here is a shot of the gearbox end of the clutch cable on the model … MFH really nailed this detail.

and the speedometer, complete with separate needle and lens …

Thanks for looking - more to come.

Cheers- RT

Addendum… more for the gear heads .

The valve lifter is a very simple device to release compression for starting the engine . While I am not certain how BSA accomplished this in 1933 I assume that it was similar to the systems I have knowledge about . Most are a simple cam device posed over the exhaust valve rocker . When the lever at the handlebar is pulled the cam is brought to bear against the rocker , cracking the valve open and thus releasing compression. Starting drill for most involves retarding timing , turning on fuel at tank , closing air slide ( choking) “tickling “ the carburetor ( a button that holds the float down to enrich the mixture) .

Kick over slowly until top compression then pull compression release until just past TDC . Release valve lifter to restore compression then a long swinging kick - if all is well it will light right up .

The technique is different for magnetos vs coil/points . Mags produce hotter spark when they spin faster, hence the reason for bringing the piston just past compression. Kickstarting bikes with battery/coil ignition general benefit from kicking at compression. Regarding retarding the ignition on manual advance machines - if you forget and try to light it up with the ignition fully advanced , it is likely you won’t do it again after your foot , ankle and leg heal …