Hello everyone!

As I talked about in another post I plan to finish another model before the show on September 9th.

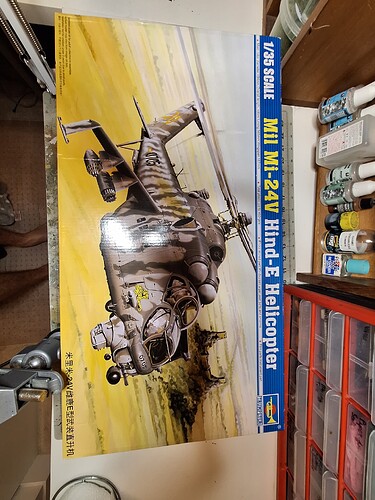

And here it is, 1/35 trumpeter hind.

This thing is MASSIVE, here it is compared to a 1/35 LAV 3 which in itself is huge.

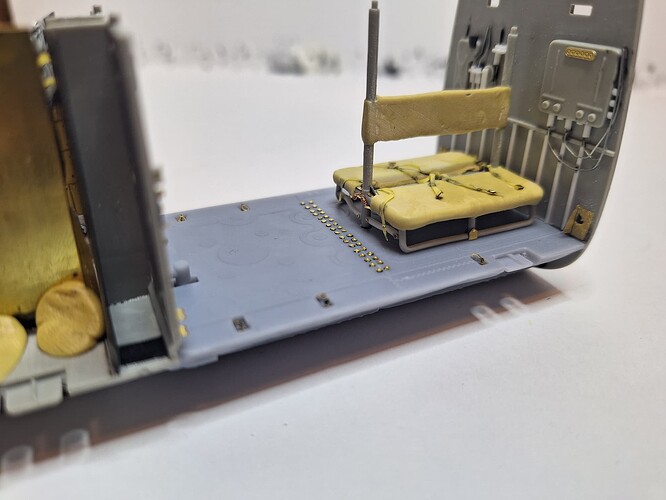

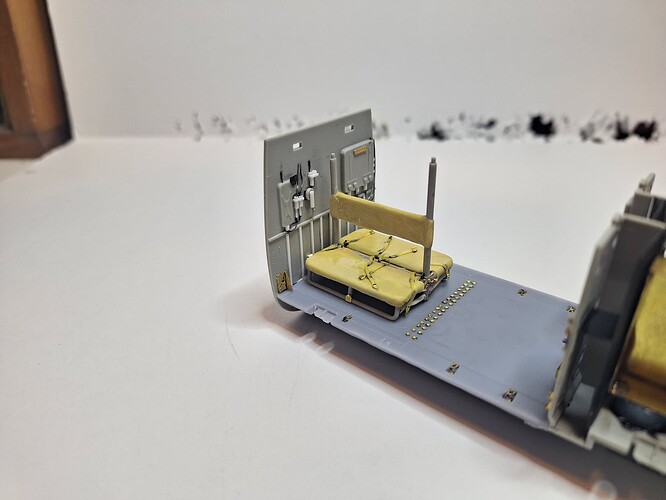

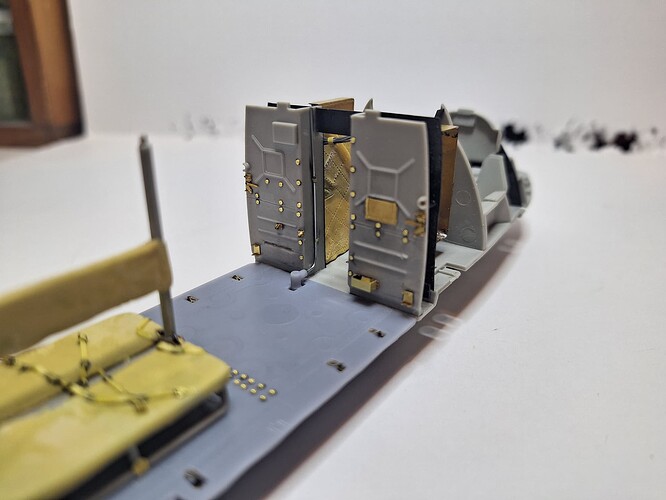

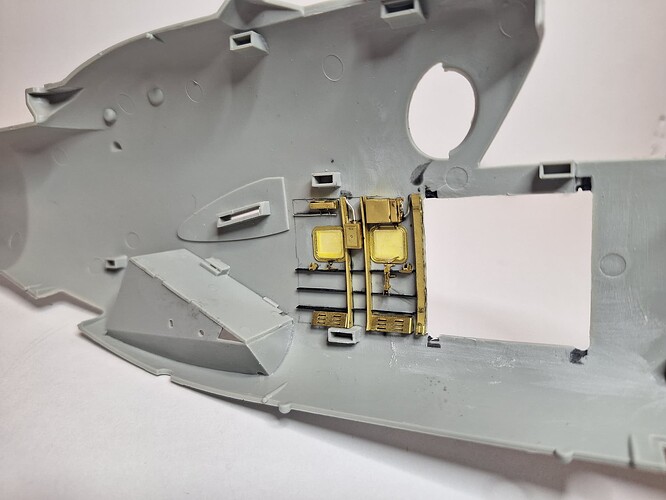

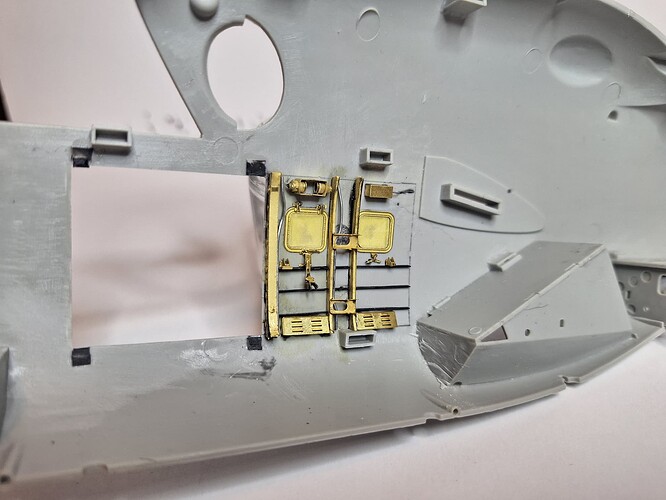

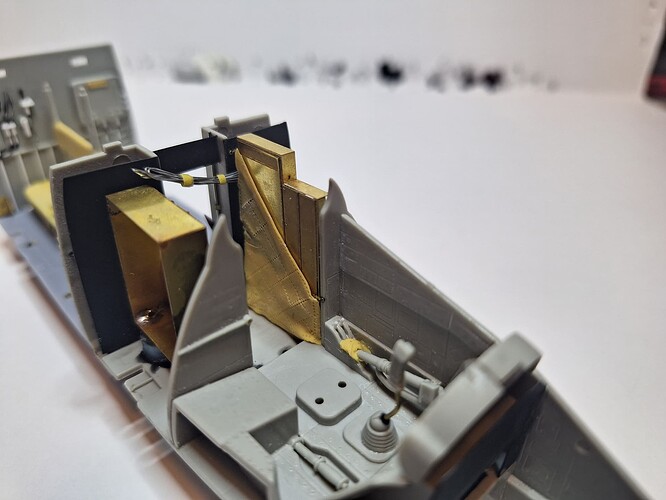

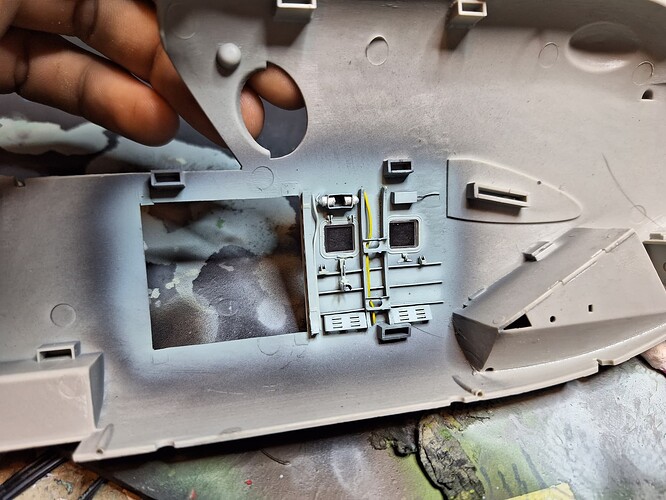

I bought it a while ago when I did not realize how intense something like this can be. I have to say though I am very disappointed in this kit. I find trumpeter to usually be pretty reliable quilty-wise but this thing surprised me. Usually, when you purchase a larger model it is because it is easier for the manufacturer to include better detail. Nah uh, not here. I was very disappointed in the complete lack of detail. As an example, the pilot does not even have his pedals and the cargo cabin literally has nothing on the walls or floor other than the bench. So I got a decent amount of aftermarket for it.

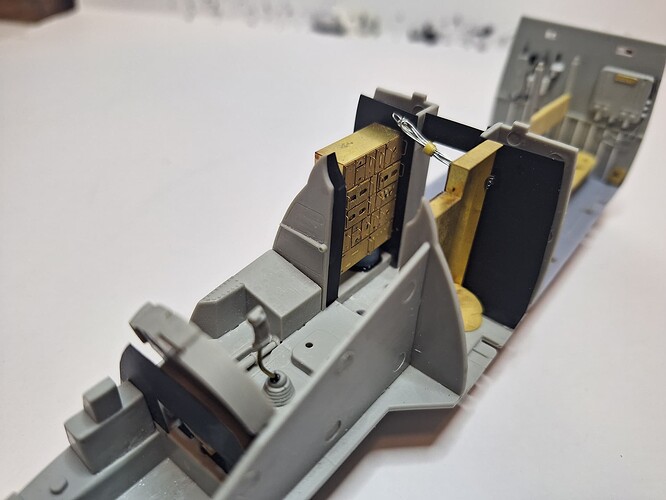

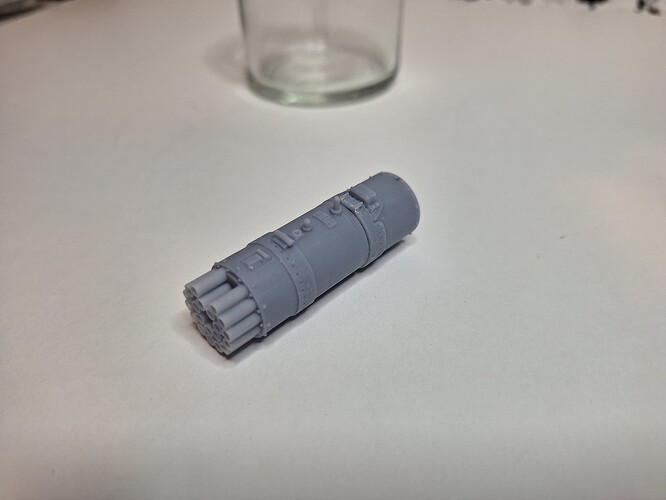

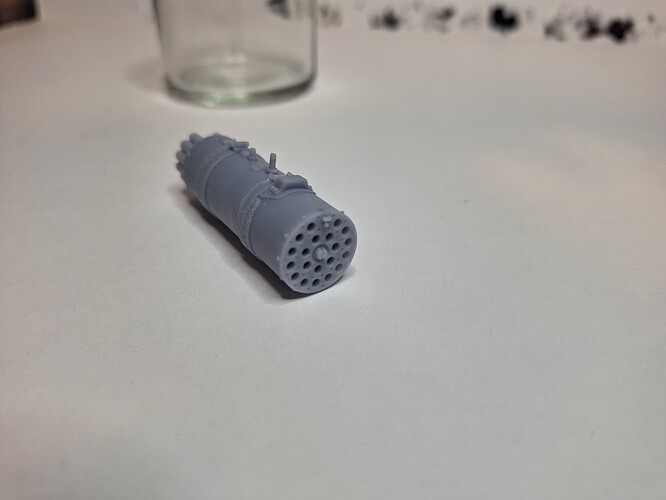

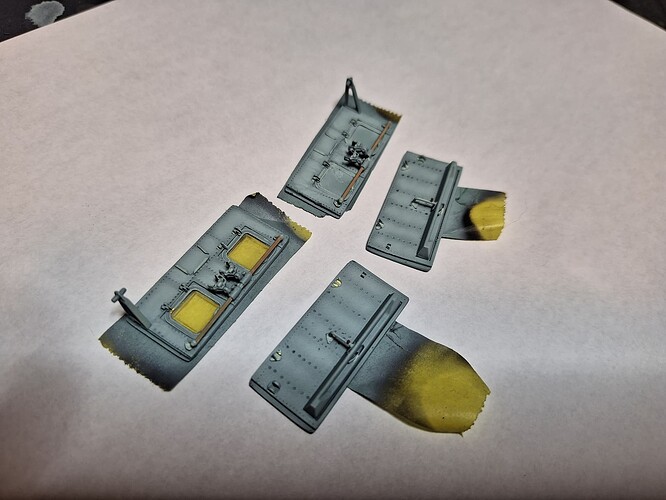

3D decals for the instruments which are absolutely beautiful, photo-etch for the cargo cabin that adds decent details. A resin and metal Gatling gun. Engine exhaust suppressor and masks. Discard the Eduard kit, it was an unexpected gift that I will probably not use.

I plan to add a lot of detail in the cockpit, mostly scratch build.

I have never built an aircraft before but I like the challenge.

This is my example for the paint job I am planning for it:

Now the biggest challenge. Getting it done by Sept 8 for it to be ready for the 9th.

The good news, fiance leaving for a week so all my spare time goes to the models.

Bad news. Basically, no time to get this thing done.

Wish me luck!