After the pontoons fiasco they needed something more amphibious…protection’s not bad compared to previous types too ![]()

Today’s midnight thought:

I wonder if Sweden has any old S-Tanks in storage they could send to the UDF?

Now that would be interesting to see how they perform and if that really was a successful design…

Who will take a try on Shapeways 3D print M777?

https://www.shapeways.com/product/2N4ANJ8A9/1-35-scale-m777-155mm-gun?optionId=191684474&li=shops

We saved a few for museums, the others have been recycled.

One photo and lots of Swedish text:

i would suggest this picture was not taken in ukraine as its dry and everyone is wearing t-shirts

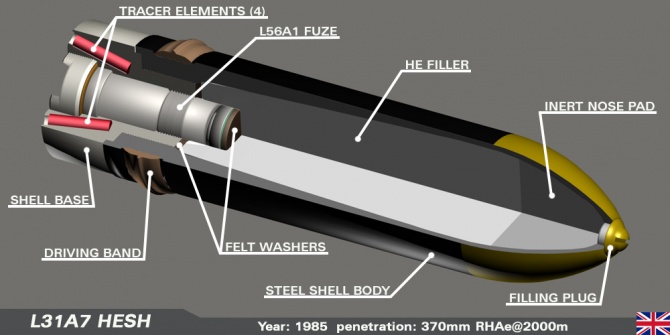

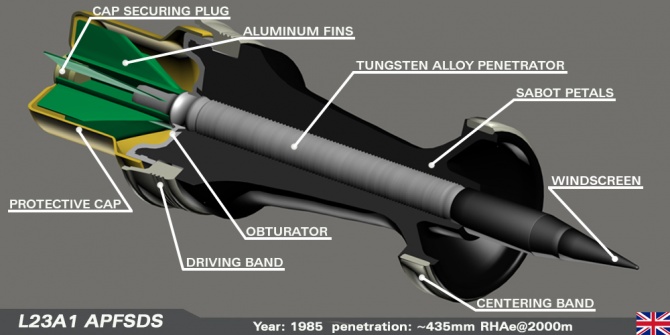

Just to expand on this, I can’t say for artillery but for tank guns (British Army) each round fired is recorded using what is called an EFC or equivalent full charge. APFSDS rounds cause the most wear due to the fact they are pushed down the barrel faster as the charge meeded to get them to the speed required to punch through armour is larger than other rounds. HESH rounds (High Explosive Squash Head) don’t rely on speed as it is a chemical energy round therefore muzzle velocity is significantly lower and the corresponding charge smaller. The wear is actually caused by the driving bands or obturating bands on the rounds which dig into the rifling to spin the round. APFSDS typically have nylon driving bands whilst HESH have copper. The corresponding training rounds have their own EFC equivalencies due to differing muzzle velocities. EFC recording and barrel inspections decide when a barrel needs changing. I would imagine smoothbore barrels have something similar although again I imagine wear would be less.

Deutsches leichtes Traktorbataillon ![]()

Many of them appear to be vets ![]()

H.P.

They probably work better and more reliable than modern ones.