New model guy, old by age. How many pairs of nippers do you own? Is the extra cost worth it for buying the more expensive ones? Do any cut so flush no sanding is needed? My 1st topic so be gentle LOL

I own 4 pair, all good. But here’s my article on them -

I have two pairs - the Tamiya I use for almost everything and the DSPIAE for cutting fine and/or fragile parts. I use the DSPIAE very infrequently. I’m on my second pair of DSPIAE because my wife grabbed the first pair and used them as wire cutters…

Ouchs

Thanks

I know I have at least 4.

Tamiya small

Tamiya large

DSPIAE

Zoukiea Mura

Those are the 4 I know I have. There are duplicates of these and others as well.

Dozen plus…three types of Xuron, Excel, Meng, GodHand, ZOUKEI-MURA, DSPIAE, 4x PIT nippers and some random junk pairs from China & Europe.

I think every modeler needs the following:

-

Heavy duty that can chop thick plastic. Some of the finess single edge blade nippers aren’t up for that. I like Xuron for mass destruction, chopping sprue and removing resin pour plugs etc. These are a poor choice for removing delicate parts or cutting close.

-

Sharp pointed nose. These help with access and sometimes the finess flat nose nippers can’t reach. ZOUKEI-MURA is fantastic for this! They are also very well made and able to do medium duty sprue chopping, remove most delicate parts and cut very close, flush to nearly flush. Mine had a burr mid point on the blade so aren’t quite up to the normal outstanding excellence. I plan to buy another pair of ZM’s soon. The angle of the nose makes them a very useful tool.

-

Small finess single edge for delicate work. The best will cut flush or nearly so when the blade is aligned correctly on the sprue gate. GodHand’s top nipper is outstanding

but DSPIAE is 99.98% as good.

but DSPIAE is 99.98% as good.

The best PIT nippers…well quality control has a little bit of variance. I have four pairs, one pair cuts ![]() just as perfect as the GodHands or ZOUKEI-MURA. They had instructions on Amazon on how to most effectively use the nippers. I liked that so bought a pair to see if they were any good despite being less expensive.

just as perfect as the GodHands or ZOUKEI-MURA. They had instructions on Amazon on how to most effectively use the nippers. I liked that so bought a pair to see if they were any good despite being less expensive.

Two pairs cut on par with DSPIAE. One pair not quite as well. The PIT’s are very good but it’s a dice ![]() roll. They were $30 so the ZOUKEI-MURA is normally the best value for ~ $38 or so.

roll. They were $30 so the ZOUKEI-MURA is normally the best value for ~ $38 or so.

I destoryed the Meng nippers by dropping them and chipping the blade. They were replaced with the 3rd pair of PIT’s which are the nearly perfect ones that cut as good as the GodHand’s and ZOUKEI-MURA.

With that said the #3 finess nipper is quite delicate. The ZOUKEI-MURA is in my experience much more durable.

HTH

Sorry…I thought it said “Nipple Addiction”, and I was going to sign up! ![]()

![]()

![]()

I bought half a dozen really cheap Chinese side cutters

which I then thinned down and “improved” using a Dremel

and diamond files. The cutting edges usually needs trimming

to get them to meet perfectly. When I do get them perfect I can

cut single hairs from the back of my hand.

https://www.alibaba.com/product-detail/PLATO-170-Hand-Tools-Electrical-Wire_1601262692158.html?spm=a2700.7724857.0.0.32e78f0617Z540

I use simple side cutters for the larger/thicker cuts and the “improved”

ones for the fine stuff.

They do not cut 100% flush. Trying to get cutters to cut so precisely that

sand paper or a file is not needed afterwards is a futile exercise.

It just gets very expensive. The cheap cutters cut very close after my

“tuning” but there is still a little nub/burr left afterwards which I then use

a sandpaper file of regular needle file to eliminate.

Even if I might find the “Holy Grail” of side cutters that can remove an

injection port 100% perfectly I still need to file/sand down the mould

partition lines left and right of the injection port.

I decided to settle for cheaper cutters and handle the residual burrs and

mould partition lines with a file.

A cheap, 30 year old, small wire cutter serves as my sprue cutter. I have yet to encounter anything the wire cutter, an equally old knife, and some quick sanding cannot handle.

Every time I look at an expensive sprue cutter, usually because of an article written by one of the gentlemen responding above, a new model arrives at my door a few days later. Not sure what is going on there. Really weird.

I was doing some fiber optic works about 10 years ago as a newb. The boss bought me a pair of some nippers they called flush cuts. We used them to cut the ends off the zip ties because they left no sharp edge for the next guy to get snagged on. Wish i knew what they were exactly?

Haha. I like them too

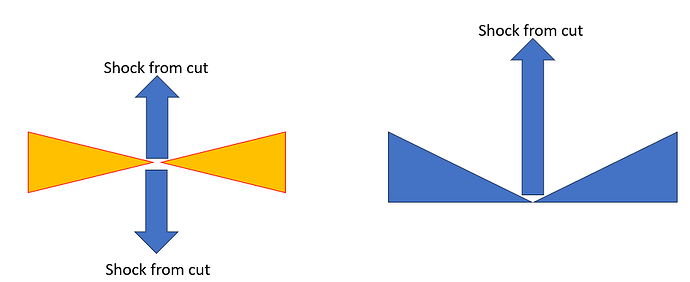

Any old side cutter (yellowish) vs a flush cutter (blue)

Flush cutters are favoured in electronics since they cut close, don’t leave a

pointed cut behind and most importantly they dont send a shockwave into

sensitive (glass or ceramics) components.

There are pleny of flush cutters in various price ranges.

The El Cheapo cutters I bought (see link in previous post) were not

exactly perfect flush cutters so I used a flat diamond file and a honing stone

to grind down the jaws until I got the cutting edge close enough to the lower surface.