I took some models into Sussex Model Centre, my local model shop, and they had a request from the Granddaughter of a 95 year old Korean War Veteran who worked on one of these in the REME, and he wants one in a glass case. So I took the job, of course, even though I have a couple of models on the go at the moment, Bismarck and the Quad, they can wait a little bit longer to be finished off. I’m prioritising the Scammell as there is a Birthday on the Horizon, so I’d better get cracking.

lets take a look, it’s a deep box chock full to the brim of lots of sprue frames containing a lot of small parts.

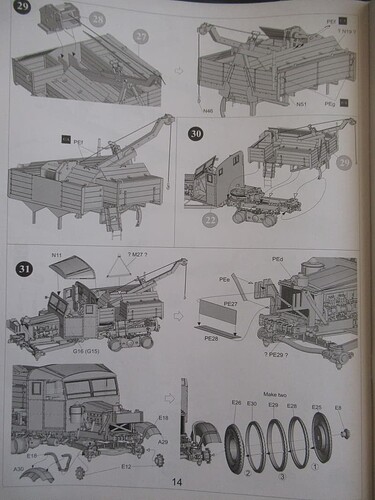

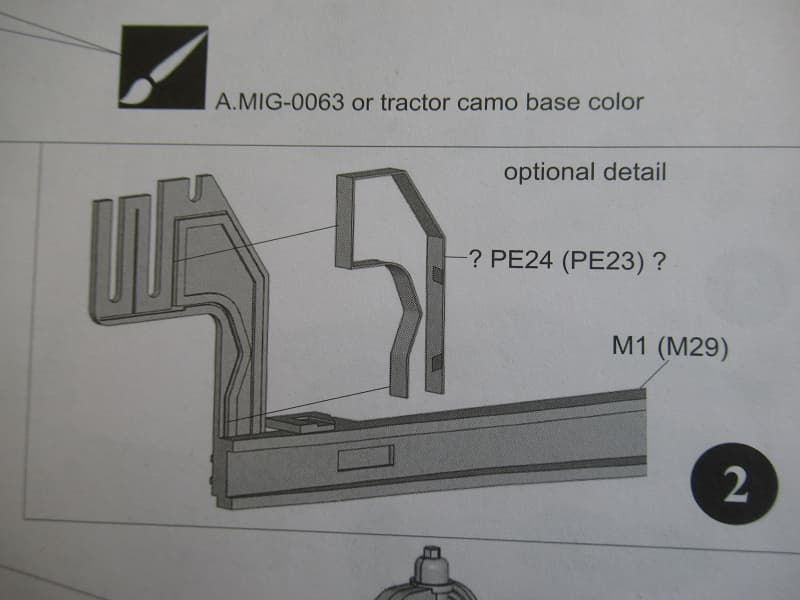

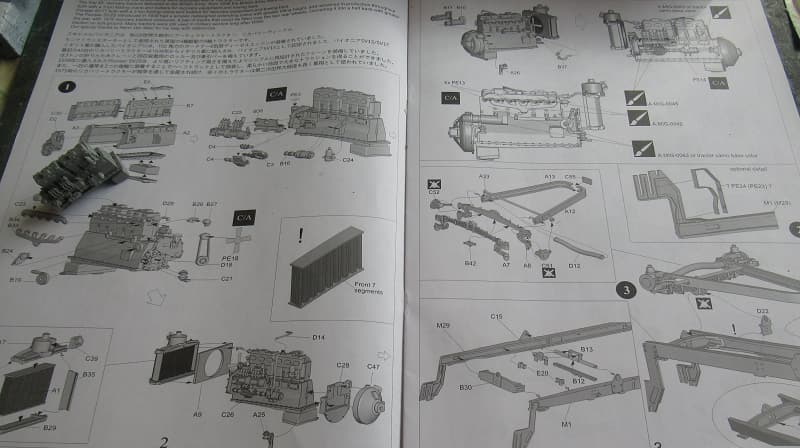

the instructions are interesting, I’ll take a good look at those and see if I need to re-order the order of assembly, like I should have done with the Quad.

I may cut some of the instructions out and apply them to the underside of the case base

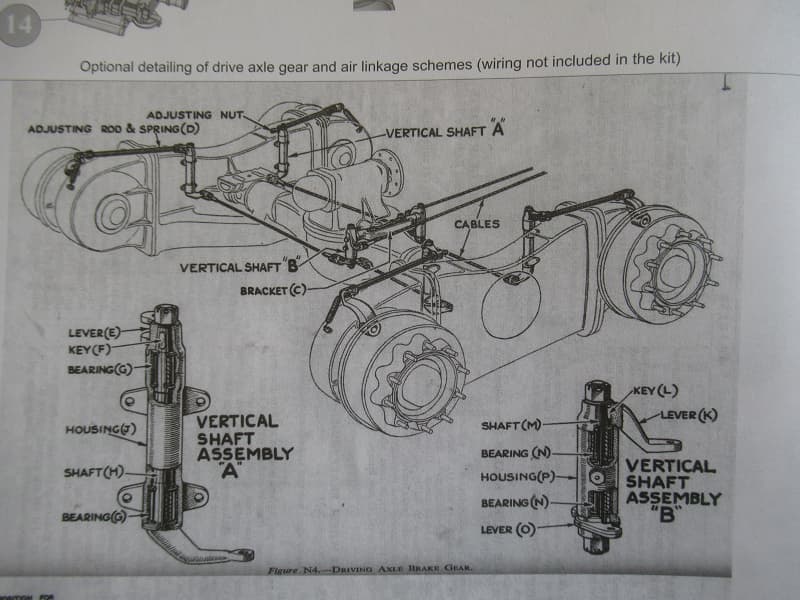

he was in the REME so he’ll love this stuff.

8 Likes

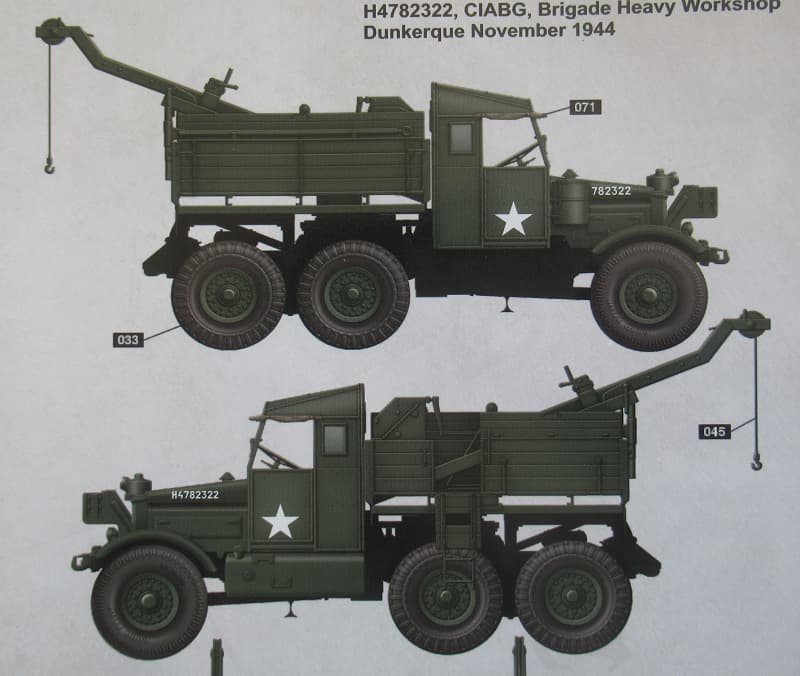

I may go for a simple all green for Korea, something like this, I don’t know about British cam schemes in Korea, I bet they were plain OD Like this 44 one.

I’m thinking of doing it on a concrete base in REME Workshops in Pusan, with a faded sign saying" keep clear REME inspection bay", or something to give the old lad a Buzz

11 Likes

Looks like a great kit. Can’t wait to see it built up. I don’t have any kits from this company in my stash so this will be good reference for me.

2 Likes

I’ll be following along with great interest.

I have had this kit in my stash since it was first released - also just received the Gecko Morris

quad … great minds think alike and all that .

2 Likes

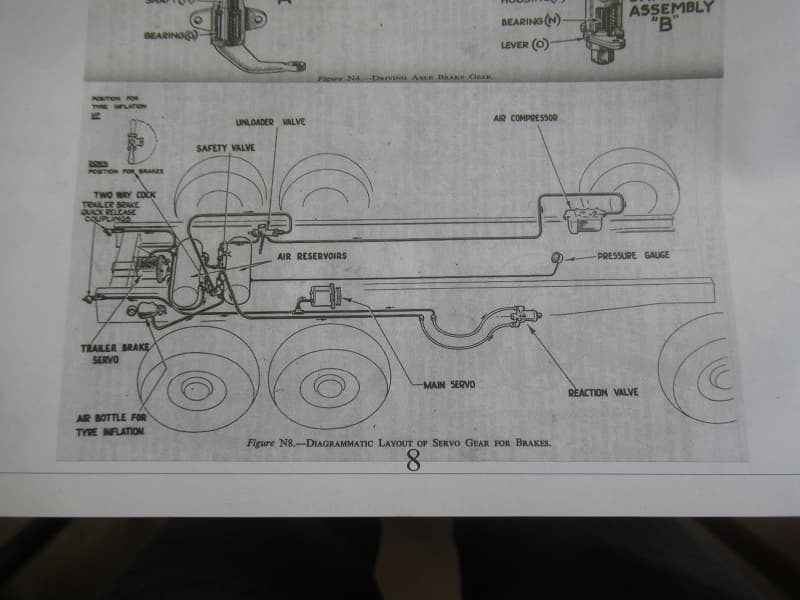

WOW! A Kit Manufacture that even gives you the piping diagrams should you wish to add even more detail!

Sweet

3 Likes

Nice kit and nice project to take on for an old vet.

I’ll be following

2 Likes

they look like they are reproduced/copies of the original vehicle manual

2 Likes

Yes but now I dont have to do the research to find the info myself! I say well done!

Now add few of the more visible lines along the frame which gives the clue that ALL lines have been added.

1 Like

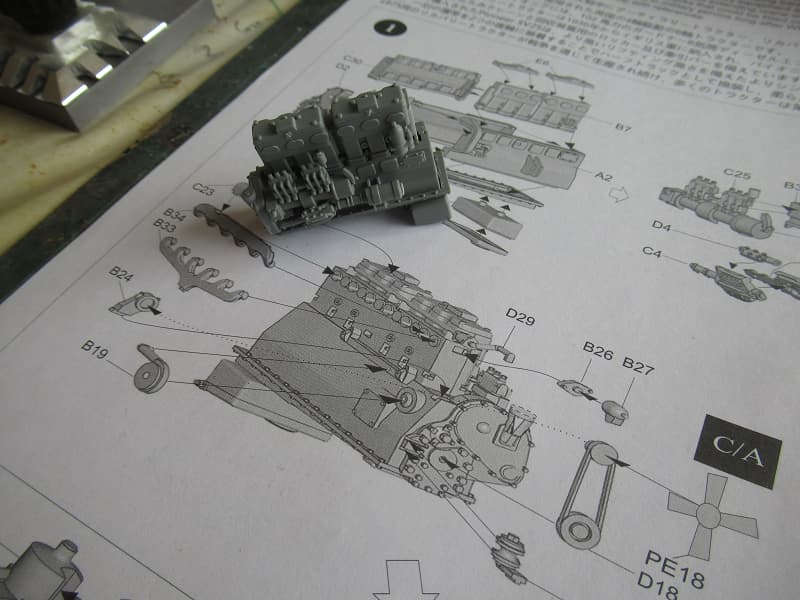

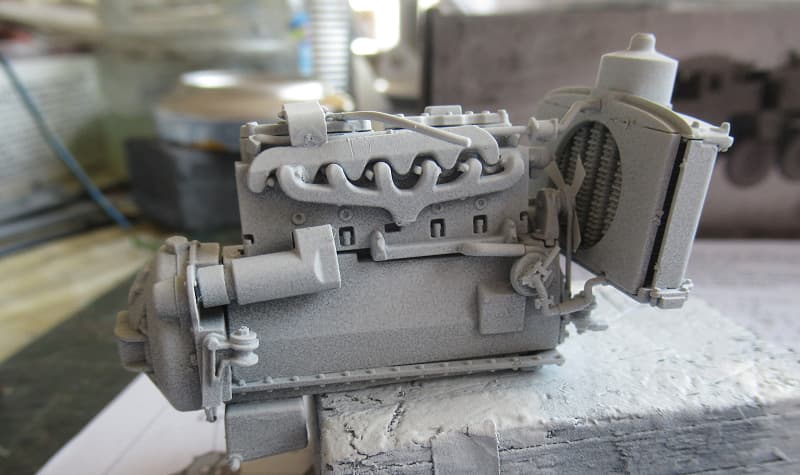

The engine is well produced neat little unit that fits together well.

it’s a 6 cyl Gardener diesel, so I’ll take care adding fuel leads using copper wire Discarded from my VW Beetle Build. still some way to go on the motor here.

8 Likes

Wow that’s excellent. May have to add this to the stash

2 Likes

One chamber for two axles and one chamber for trailer brakes?

Ugh.

1 Like

Here’s one belonging to the 16th Infantry Workshop REME in Korea (1952)

H.P.

5 Likes

Engine braking, old diesels …

Edit: Modern diesels in cars have almost no engine braking since engine braking makes ABS brakes useless. Foot ever so slightly off the pedal and the drive wheels lose the little grip they had.

My dads old Mercedes would have you leaning forward in the seat if you released the pedal too quickly.

Even petrol/gas engines have too much engine braking to function well with ABS brakes.

2 Likes

Wow; that prompted a trip down memory lane. There was still one of these in 82/83 at Airfield Camp in Belize when I was there.

Massive great thing in Deep Bronze Green; REME colours (red, yellow, blue) everywhere and I seem to recall a large cast Corps badge on the front of it. I vaguely recollect that the bonnet sides were removed and one could glimpse the engine block, mainly coloured – and here I am racking my brains a fair bit – a sort of duck egg blue/green.

Anyway, by the by really. Just a prompted memory back to the searing heat, attaps, Belikan beer, and, and, shock, horror: they sent the clerks up the jungle!

4 Likes

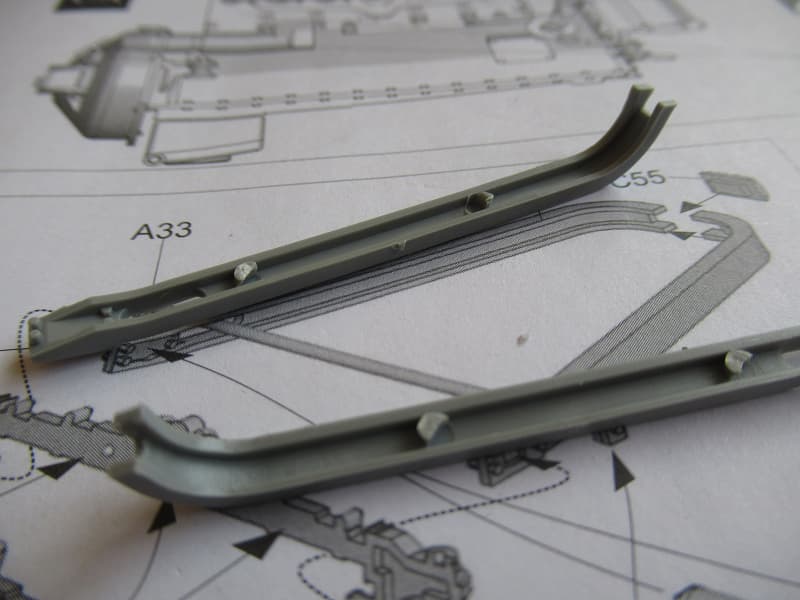

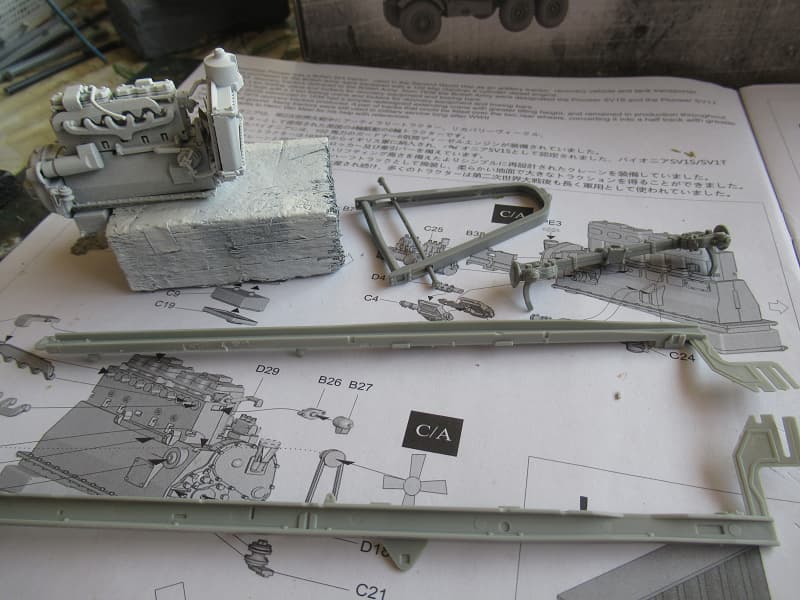

There are some kit issues that are annoying more than problematical, these moulding protrusions inside the U channel of the engine bearing arms. After cutting them flush they have to be sliced and the residual mark scraped clean.

the engine kit assembled, I may add some wire fuel injectors if I feel brave enough.

next up, adding a complex pe bend to the front of the chassis legs.

11 Likes

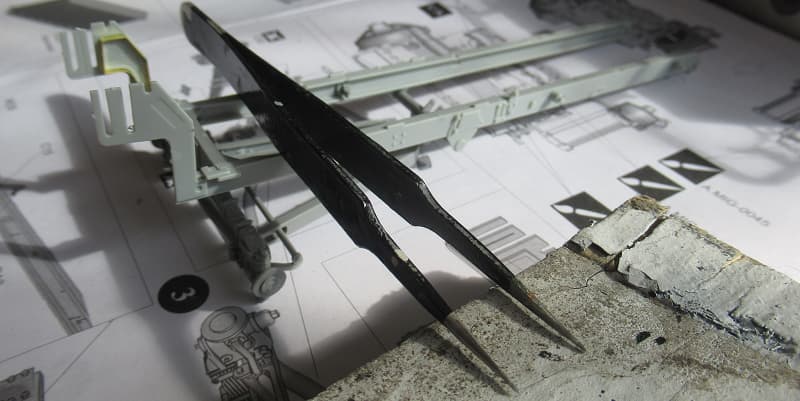

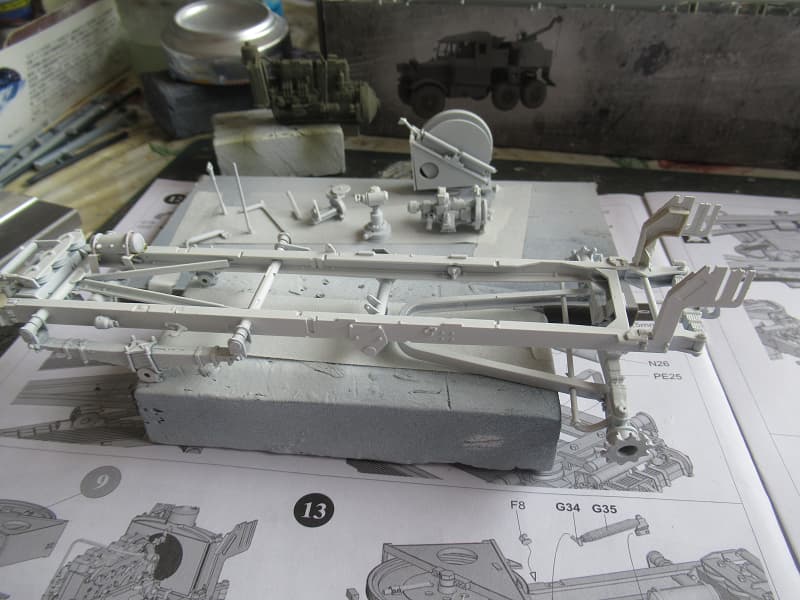

joining up the ladder chassis using the tweezers on a block to make fine adjustments to get it all square.

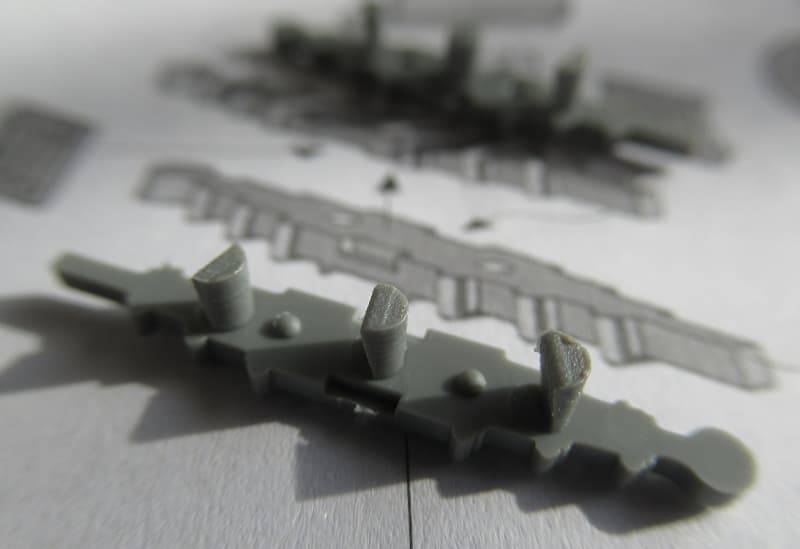

These are the molding pegs I spoke about earlier, except here they are flush mounted and easy to clip and sand off.

they need to be flush as they join together flat to form a leaf spring.

7 Likes

The chassis for this and the Morris Quad I made recently are intensely complex builds, with parts fit from time to time being rather vague.

winch fit is one of those vague fits, I doubled up the hold to the chassis by reinforcing the areas touching with light traces of superglue gel. The chassis engine and winch in base colours.

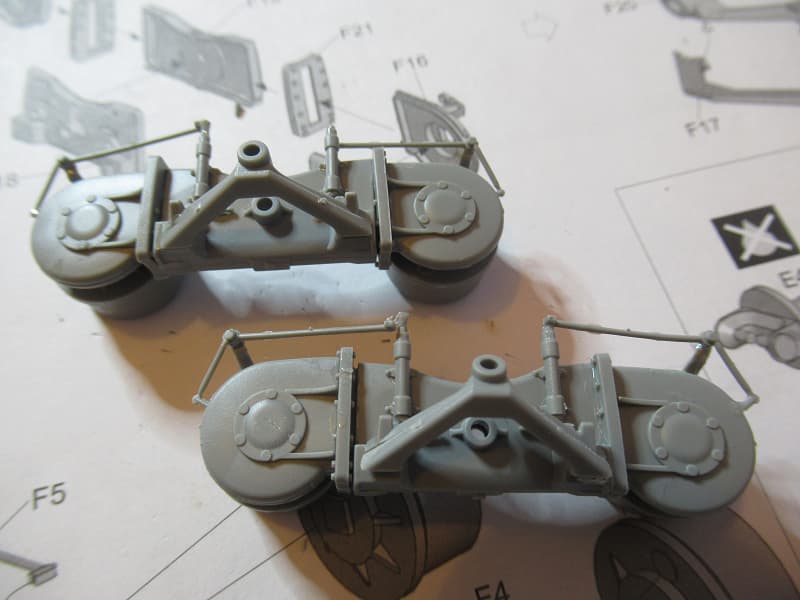

the final drives are made up from 16 components each.

10 Likes

I’ve always had a soft spot for this truck. Go anywhere do everything. Even off road rally… they’re just so fugly they’re beautiful…

2 Likes