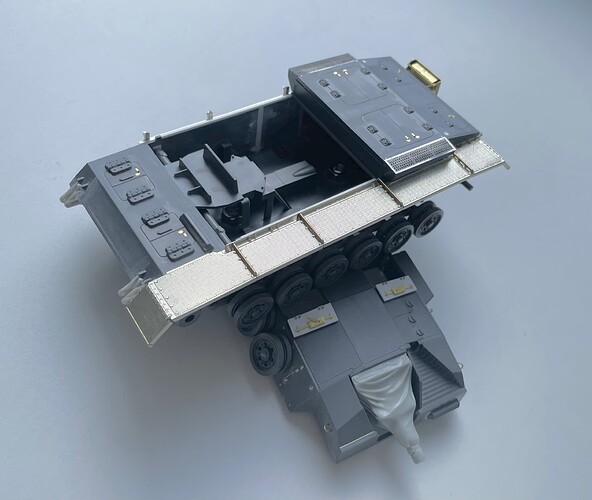

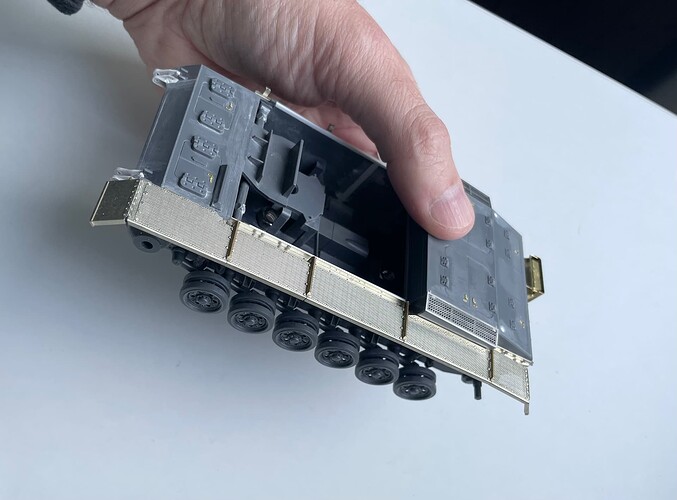

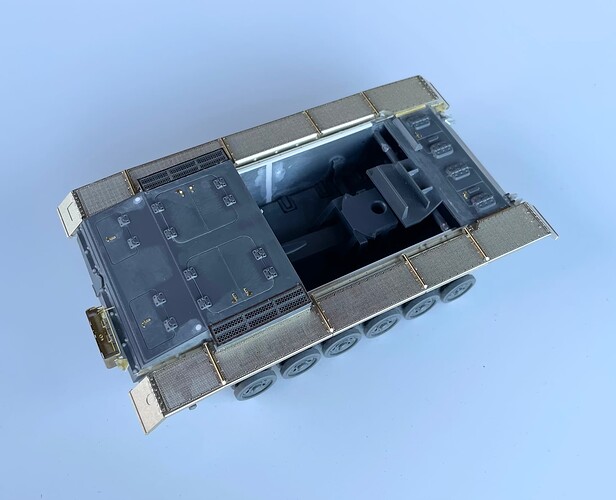

This project has been benched for quite some time……. I was virtually complete with the first etched gaurd, which to be honest was a real challenge, fiddly to work on, and a real head scratcher to figure out the build sequence.

I thought i’d cracked it…… until I realised I hadn’t.

I had got the front fender misaligned…….

And at the time I thought superglue was a one way street, no backing out.

A few months passed, then I found out about debonder…. but that didn’t work.

A few more months passed, and then I found out you could dissolve super glue with acetone…… so I gave that a go. Worked! pretty harsh on the plastic though.

So, the alignment issue was fixed and 8 months later I have completed the first gaurd

Onto the next one now, pity I have forgotten how I did the last one

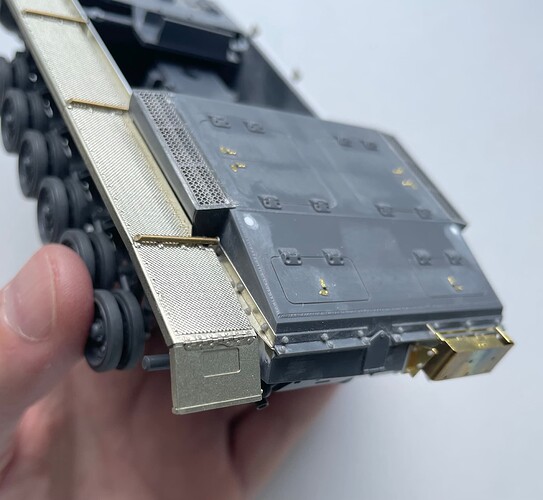

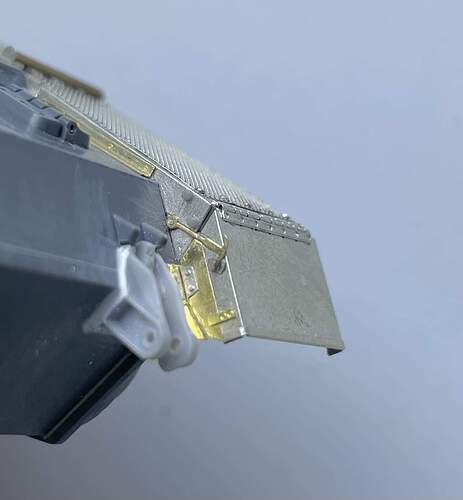

The problem was that I had glued all of the main fender in place, rigid. The front hinged guard was still able to move on its hinge, but other than that had no scope for adjustment. When I fitted the brass coloured item below the front flap, there was about a 1mm gap between the brass part and the front flap, with no way to close it up…… which looked absolutely terrible.

However, use of acetone allowed me to remove some of the parts and have another go. Below has now been fixed so there is no gap…… although there is another mistake below  but far less obvious so i’ll let this one slide…….

but far less obvious so i’ll let this one slide…….

I have to say…. I don’t think I would recommend this combination of these aftermarket fenders with this kit, they don’t play nicely.