The M75 is another subject that interests me. I have long thought the M75, M59, and M113 are some of the most logical armored vehicles ever built. The most efficient way to build an armored box…is to build an armored box. (I will leave it to someone else to discuss the benefits of angled armor or make the case for Kugelpanzers.) In my opinion, as armored boxes go, the M75 looks pretty good. As grandfather(?) of the M113, it is a historically important vehicle.

So Hobby Link out of VN just announced M59 APC as a 3D print kit in 1/35:

wannamakerhobbies.com is the US distributor for Hobby Link.

Hey James,

Can you post some screenshots of the HL M59 for those of us who can’t/won’t do FB?

Hi Al,

So far, that’s all it posted. I’ll post more photos here when they appear on FB.

Al and all,

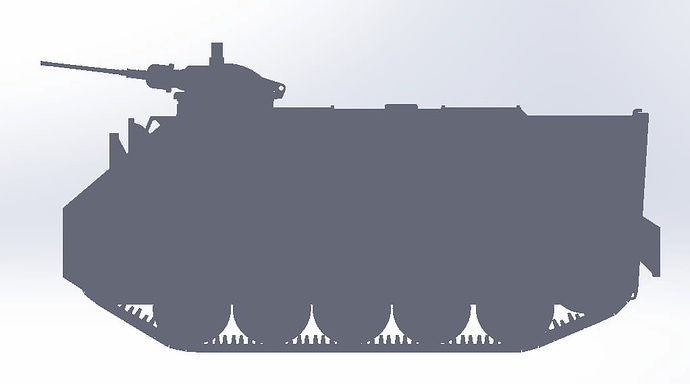

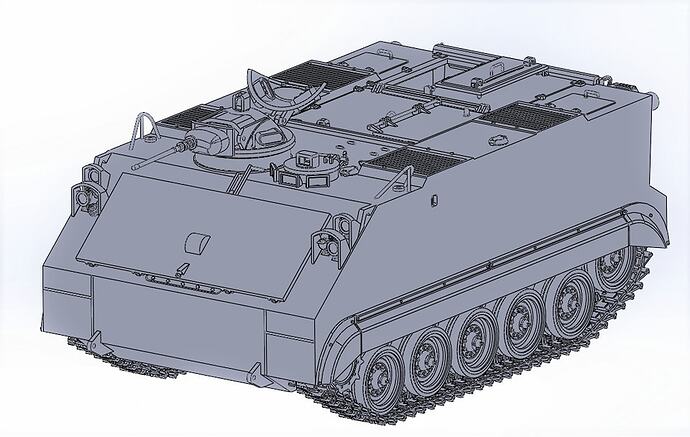

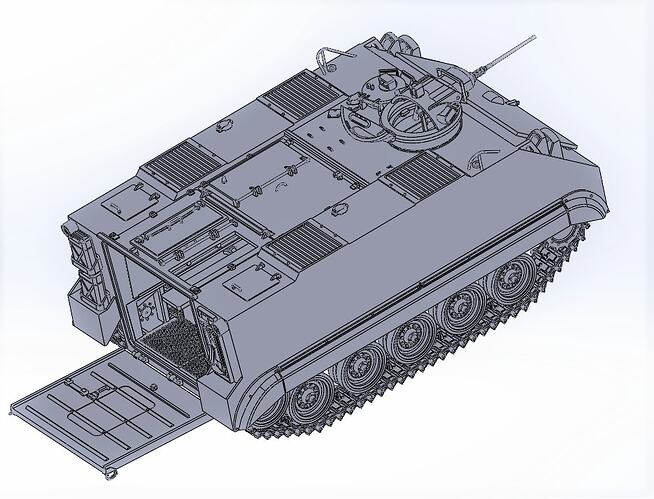

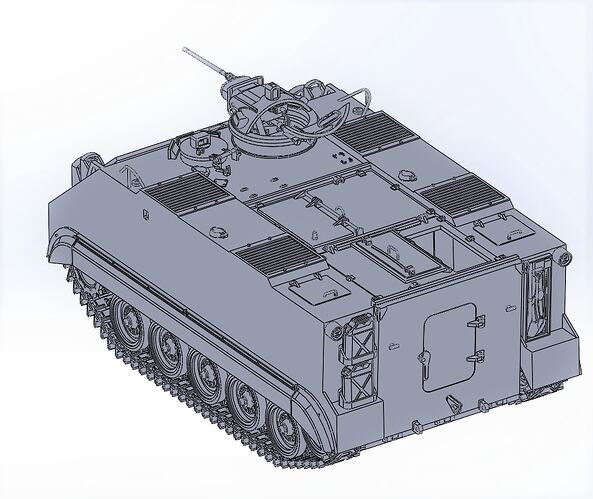

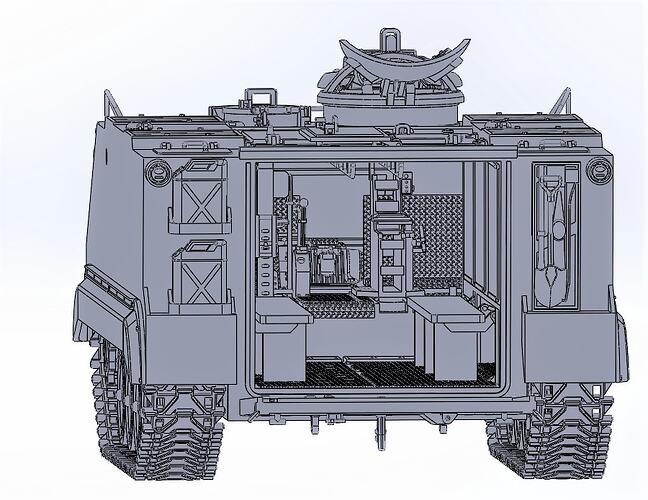

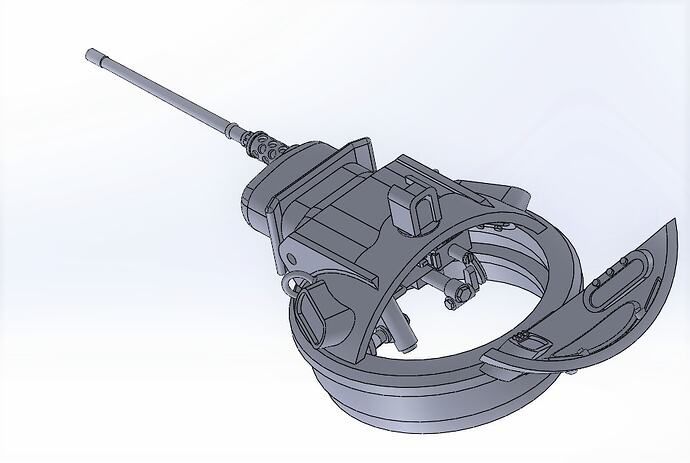

More CAD screenshots of M59:

Looks like he may be using Solidworks software to build it.

It’s up on Wanamaker for preorder.

Also new, M56B1 maintenance truck

Fuel tanker trailer M131A2

And M54 logging/timber truck

Would make my day if hobby boss would do a new tool Sd.Kfz.138/1 Geschuetzwagen 38M fuer s.IG.33/2, they already do the Marder M so it would be welcome. I know dragon did one but it is hard to obtain now

Well there you go. You guys finally got your M59. ![]()

Can’t wait for:

Zvezda Ka-52 in 1/48

Zvezda Gaz-66 in 1/35

Dream about buying:

Typhoon K

Typhoon VDV

T-80U

Abrams M1A2 SEPv3

Merkava 4M

Challenger 1

Challenger 2

Type 99

S400

Chieftain Mk.X

A7V

Mk.VII

Saint-Chamond

MAZ-537

SCUD-B

Well now that we have the Ward LaFrance heavy wrecker coming in plastic, how about the Autocar and Federal truck tractors of the WWII - Korean war period as well as the trailers to go with them. Available in resin but I would appreciate the ease of styrene construction.

Centurion mk5 Bridgelayer , please

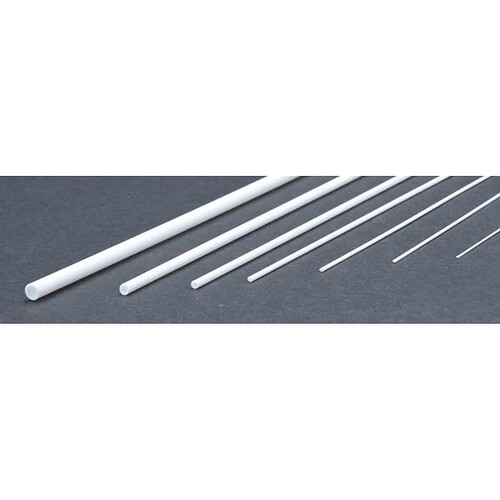

I know that this may sound strange or silly since one can make it oneself, but I’ll just ask for it because I’m surprised no vendor has ever sold any…

Stretched sprue of different thicknesses, essentially straight plastic rods about six inches in length of varying diameters.

I made stretched sprue before, but if done incorrectly, the problem is that the stretched sprue coils and curves around into a loop or circle, or the diameter varies.

I’ve used piano wire, but that is heavy, sharp, and can scratch adjacent built models.

I asked an online hobby friend for stretched sprue and he sent me sprues of varying diameters which is what I want. However, we no longer communicate due to “email ping-pong games.”

Wish that Ryefield Model’s would do:

251/C

251/D

232 6 rad

231

232

222

@HeavyArty Yes, I have some very thin styrene rods; however, I find that they don’t bend as easily as stretched sprue because these are Architectural scale model products and are meant to have some structural stiffness.

I might contact a modeler here and pay for some stretched sprue…

![]() The key to getting sprue to stretch the way you want it depends upon a few factors: Closeness and/or type of heat source, length of sprue you’re heating at one time (and you’ve got to rotate it as you’re heating it) And even the sprue type. Sometimes you’ll find that the piece you’ve chosen is actually hollow. And finally, how quickly you draw it out. If you don’t want it to curl up you’ve simply got to keep it stretched out for a bit. Trust me - I’ve nearly made a science out of this. I stretch sprue primarily to fill in holes in a kit. I want two cone shaped ends from where I draw the sprue out. That way I can slather liquid cement on the cone and twist it into the hole. It’s practically self sealing. It’s also great for fixing errant holes I’ve drilled out. It happens.

The key to getting sprue to stretch the way you want it depends upon a few factors: Closeness and/or type of heat source, length of sprue you’re heating at one time (and you’ve got to rotate it as you’re heating it) And even the sprue type. Sometimes you’ll find that the piece you’ve chosen is actually hollow. And finally, how quickly you draw it out. If you don’t want it to curl up you’ve simply got to keep it stretched out for a bit. Trust me - I’ve nearly made a science out of this. I stretch sprue primarily to fill in holes in a kit. I want two cone shaped ends from where I draw the sprue out. That way I can slather liquid cement on the cone and twist it into the hole. It’s practically self sealing. It’s also great for fixing errant holes I’ve drilled out. It happens.

Use the same sprue as what’s in the kit and the repair is nearly indetectable. If you’r wanting tapers for antenna you simply draw it out fairly fast at first and then slow down to gain thickness. Experiment with it. For God’s sake don’t pay someone else to do something you can do yourself. Besides, as I said, you want the sprue from the kit. Not some crap Joe Bob has left over from an Eastern Express kit.

I would be very happy with an RFM 251D. I almost bought the AFV club one but apparent some have a top to bottom hull fit issue

Would also be pumped if RFM tackled the Cromwell

I believe the operative word here is some. That tells me the ones that had fit issues were modeler induced - usually in a case where there are large mating surfaces it’s from not thoroughly removing the sprue gate. The tiniest remnant will throw the whole joint off, causing the reviewer to proclaim it as junk.

I agree usually but in this case the problem was actually a mold and design issue that AFV Club fixed on later releases.

As far as i know though you can’t guarantee which you’ll get from kit number alone as earlier moldings had issues and later ones didn’t for the same kit number

In my experience, another “trick” when stretching sprue is to do it vertically: that way, it is much easier to hold it until it’s hardened again, plus it comes out absolutely straight.