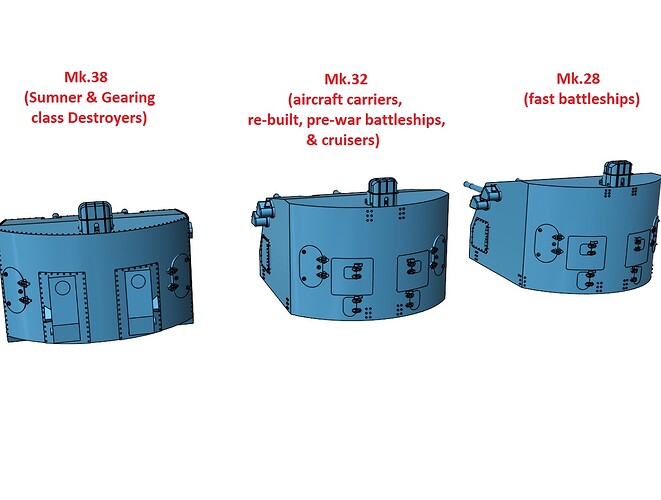

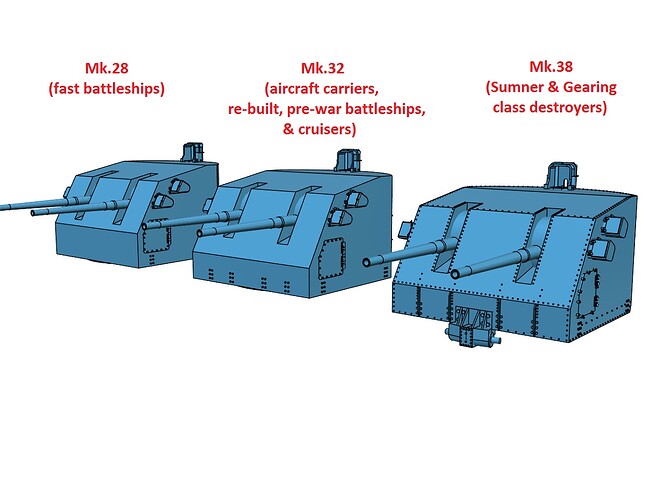

After the success of building the 1/72 scale 16" Turret from Keel to Gunhouse, the Battleship New Jersey Museum and Memorial has agreed to permanently display a similar rendition of the 5"38 Mark 28 Twin-Gun, Multipurpose Gun found on almost every WW2 (and later) ship.

To refresh your memory, here’s the 16" project as presented to the ship.

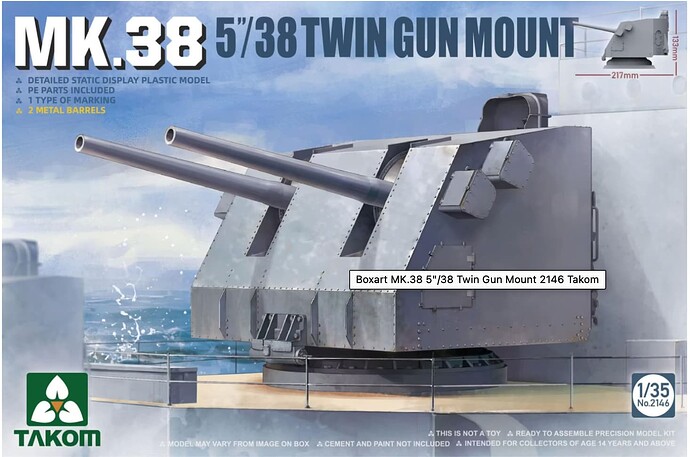

When Takom came out with the 1/35 kit of the 5" Twin turret I thought just maybe doing it again.

I contacted Ryan Syzmanski, the Big J’s curator, and asked if he would like to have a companion to the 16" turret now on permanent display in the Ship’s ward room. He immediately responded that it would be a good addition.

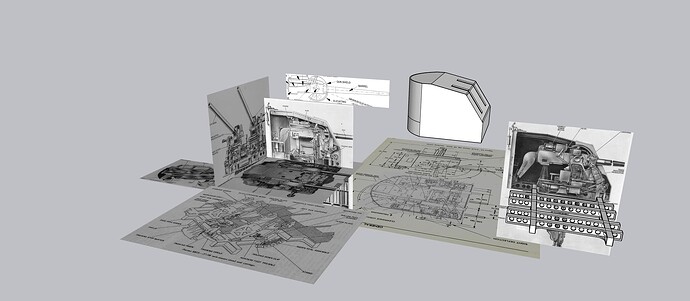

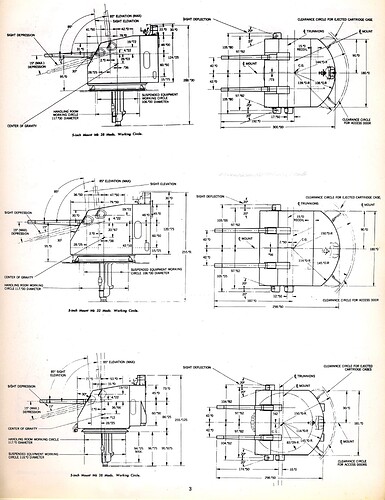

I’d been collecting reference information about the twin turrets (and the 40mm quads) for years along with my 16" research, but this past week got into full swing. That includes reading the entire service manual of the turret. Service manuals give you some line drawings that are exceptional value.

I had a lot of lessons learned with the 16" project and hope to apply them on this build. I’ve also had in the back of my mind that other muesum ships may want similar models. As far as I know, no one had ever created an Iowa turret complex like the one I built and have similar thoughts about the 5"38s based on my internet searches.

One of the first things I learned is don’t get too far into the design until you have the model in hand. I had a terrible time getting the main gun alignment with the Iowa turret since it was dependent on the openings in the front face of the plastic gun house regardless of what the plans showed. The Takom kit comes with the metal barrels included so I won’t have to special order that.

I imported relevant drawings into SketchUp 2023 and scaled them based on the actual sizes given on the one drawing that shows some critical dimensions. With that I could be secure in the knowledge that all the drawings were agreeing with each other. As with the Iowa, most of the drawings had no dimensions so it was all about good estimating.

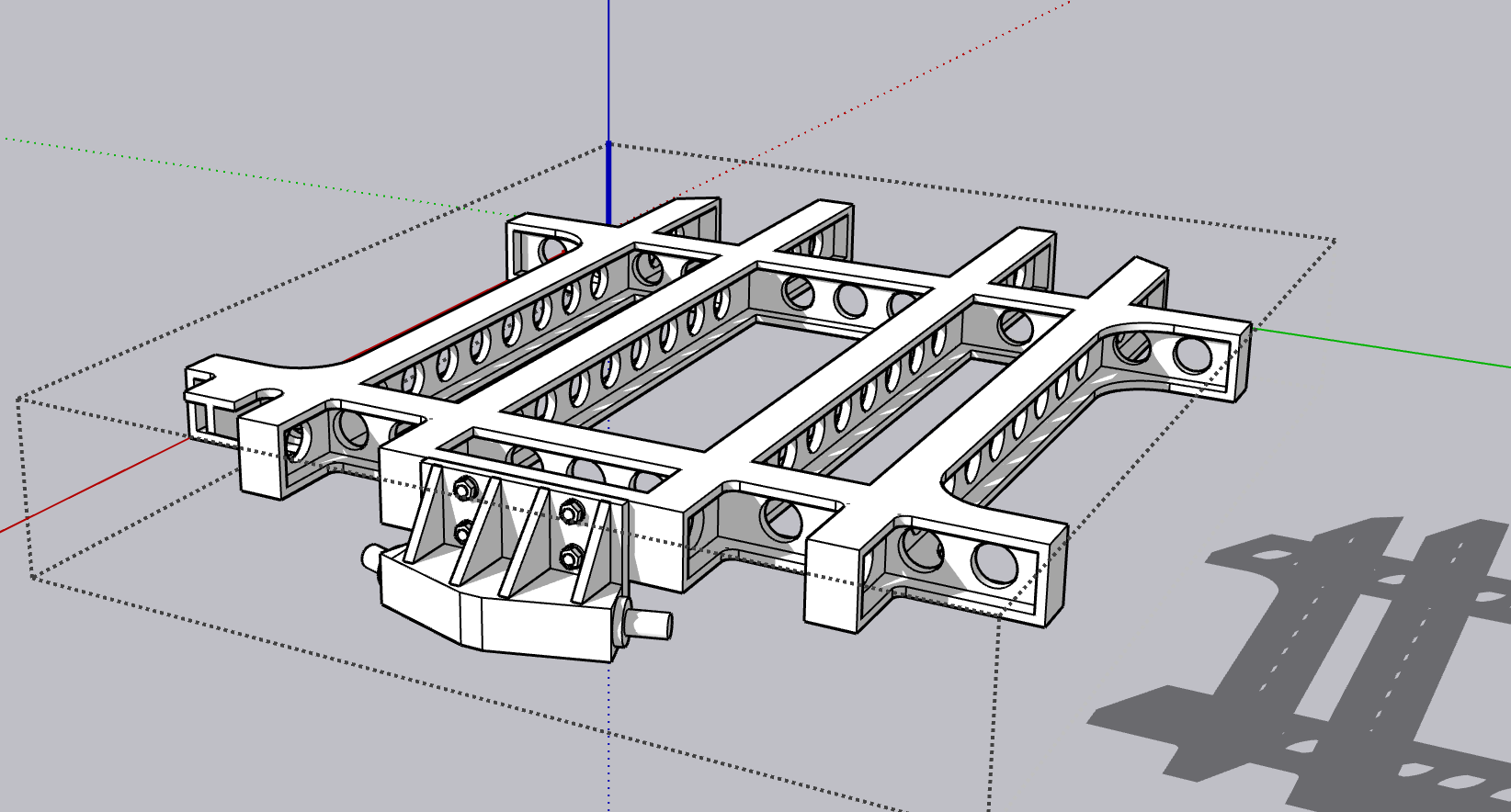

I’ve already done too much desiging the subframe that supports the two pairs of gun mounts. For example: Just looking at the box art I see that the training buffer (device to stop rotation before the turret hits something it shouldn’t) is already attached to the exterior of the turret. I don’t see that detail like that on the battleship turrets. So I have to do more research. While the guns were essentially the same in all of its applications, there were slight differences. I’m doing the battleship version. Another example is the base ring. I can tell already that the box art is not a battlehsip application.

While my drawings show pretty good renditions of the floor plans of the turret, I have no idea how this relates to the Takom model. My main reason for doing the drawing was to ensure that my 3D printer could produce it in a single part. I just fits.

This is the subframe.

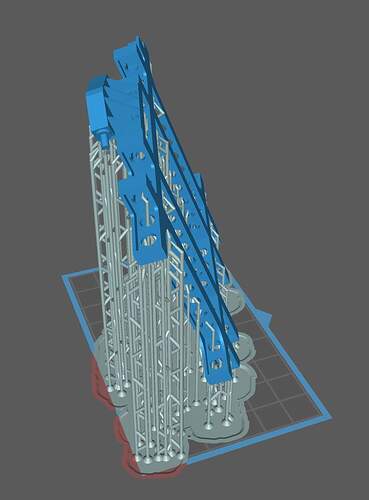

And he it is tentatively put on the 3D printer slice (ChiTuBox). I am not printing this! I don’t know if it’s correct or not until I get the model. My LHS has ordered another kit since he sold his last one.

Here’s the test piece on the slicer. The red areas are out of the print range, but are just small parts of the raft that won’t matter. That said, every other angle to which I rotate the object puts some part of the actual part out of the print range. So it JUST FITS. Convenient!

I have the Takom Apache to build so this project may or may not get started first. Depends on when I receive the Takom 5" turret model. I’ll start the Apache and put it aside when the turret arrives. Building for the battleship takes precedent over models for my own collection.