On Monday the model will be done! Today was a mishmash of tasks to finalize the build. And there was the usual passal of complications that seem to crop up at the last minute. Alls well that ends well" sums up the day.

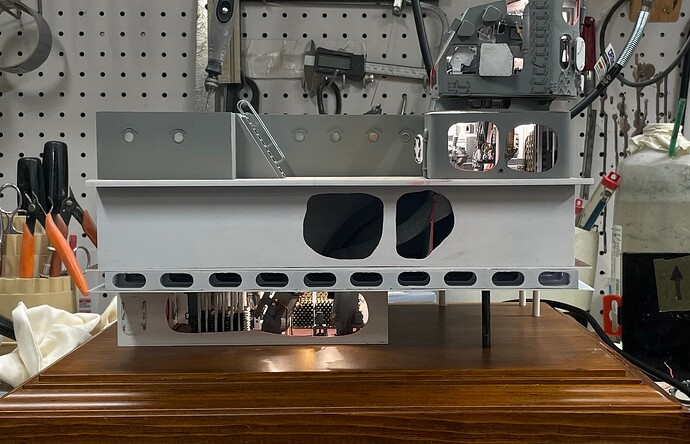

I started by fabricating the brass clips that would secure the case. I was halfway through when I realized that I should glue the GH/UHR assembly since it would need a good hour of setup time before I could handle the model. To do the wiring it had to be in place and be able to let me lay the case on its side to access the bottom.

I marked its location on the deck and applied the J-B Structural Cement so it did not ooze out of the edges.

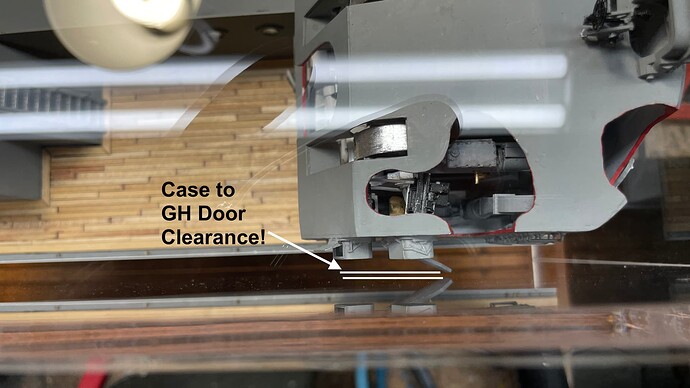

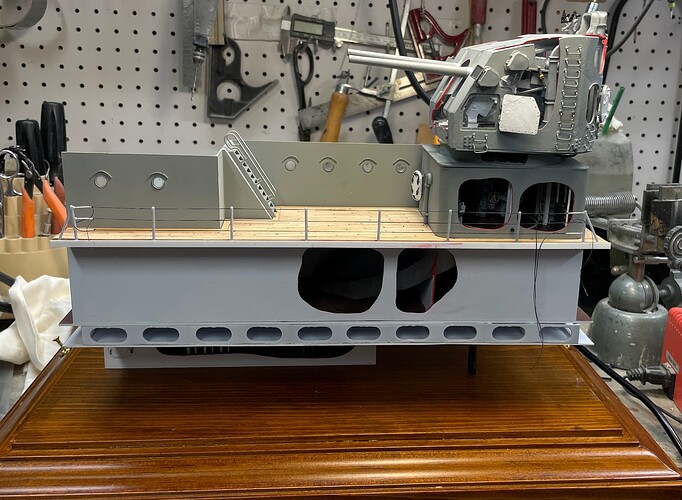

The assembly sits just a bit proud of the superstructure bulkhead due to the screw heads protruding. Believe it or not, this little bit almost caused a problem.

While drying I got back to making the locks.

Before drilling I did a bit more flame polishing. In the lighting where I was doing this showed that it wasn’t done enough. I also overdid it in one spot. Yes… you can overdo flame polishing.

Drilling acrylic can be tricky due to fracturing upon exit at the hole’s bottom. To counteract I used masking tape on both sides. It also provided a place to mark the locations.

The bracket is screwed in from the back side and passes under the end acrylic sheet. The 1/16" gap came in handy for this and I used it.

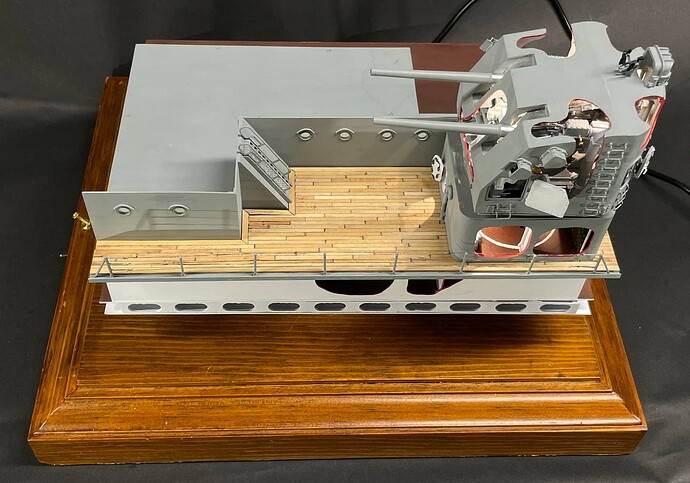

I fit the case over the base with the model in it and found that I only had a fraction of an inch clearance between the open access GH hatches and the plexiglass. Luckily, I built in some play and was able to scooch the case forward a bit to gain just a bit more room. I was very, very lucky. I was concerned about the protrusions on the gun house as I drew it and the base, those open doors were not in the drawing. If it didn’t fit, frankly, I have no idea what I would do.

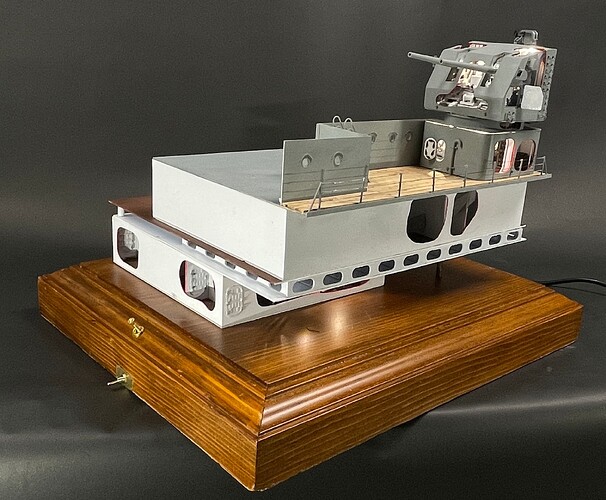

With the case positioned properly, I drilled the pilot holes for the flat-head brass screws with dress washers. Came out nice and neat.

And with the case on.

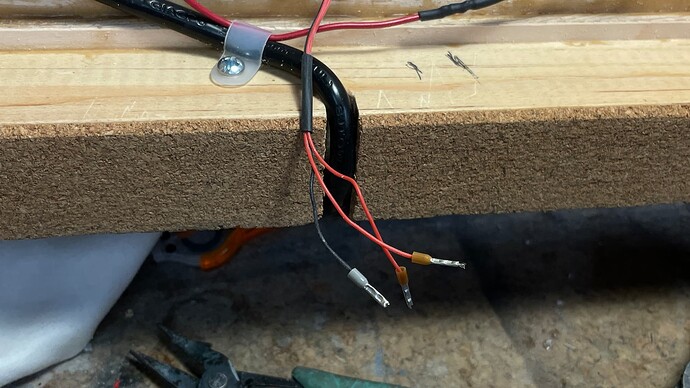

With the case fastened, I was able to tip the model backwards and terminate the light leads. I had passed the GH/UHR leads done the conduit tube before gluing in place.

I bought some very small gauge ferrules from Ferrules Direct for the 32 gauge wire I use with LEDs. These protect the delicate conductors and make connections into Euro-style terminal strips must more secure.

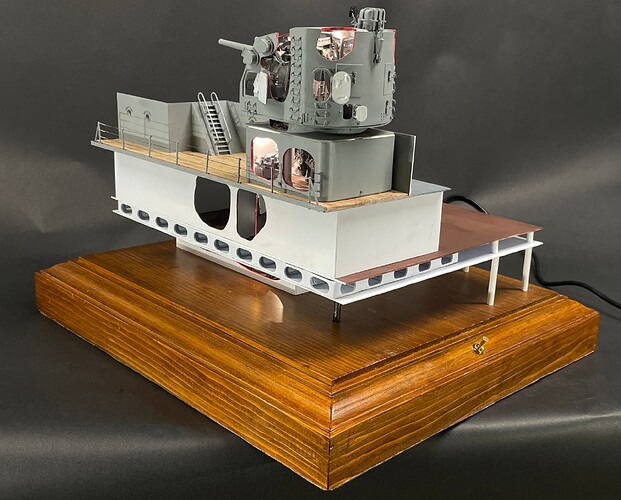

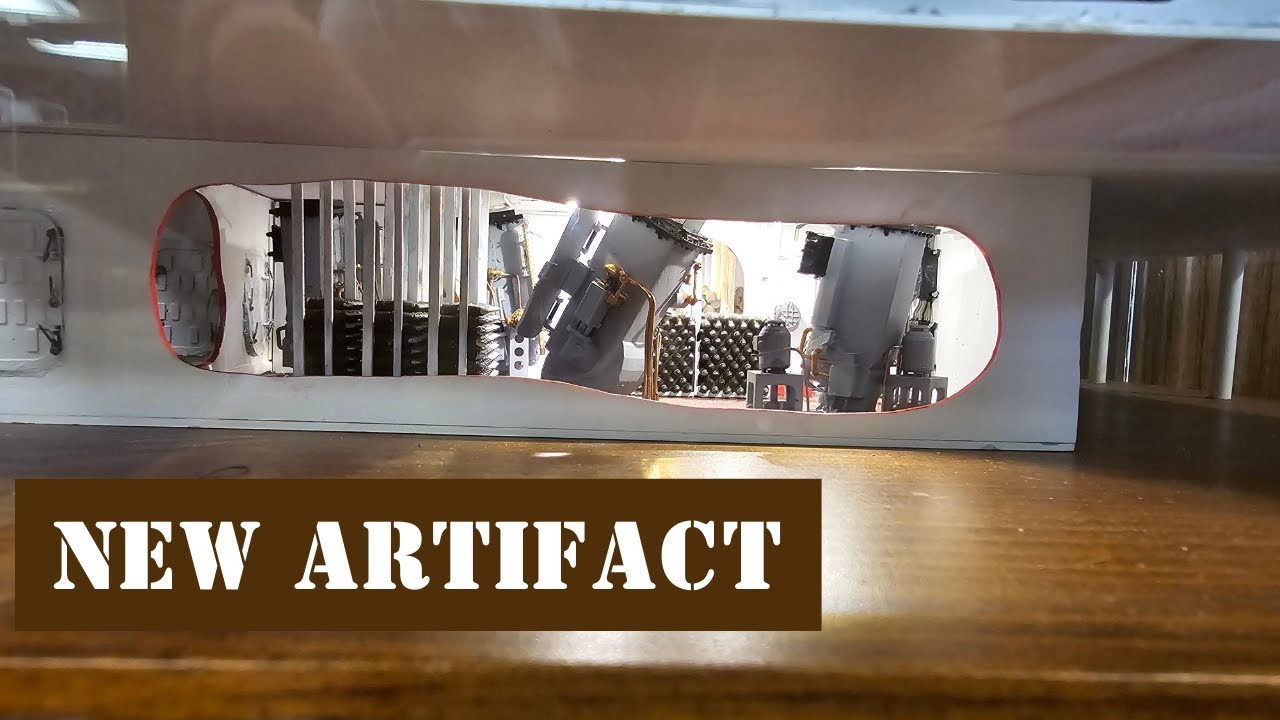

Making the connections only took a few minutes. Then I tried the lights and they ALL WORKED! Excapt for one thing… the lights in the magazine were very yellow, like high pressure sodium lights. Oh darn! I never took off the tiny pieces of Tamiya masking tape I applied to protect the LEDs from painting. The magazine is very difficut to reach now, being set way back.

Using this long machinist’s scribe, I was able to reach them even in the powder room and remove the tape from the lights.

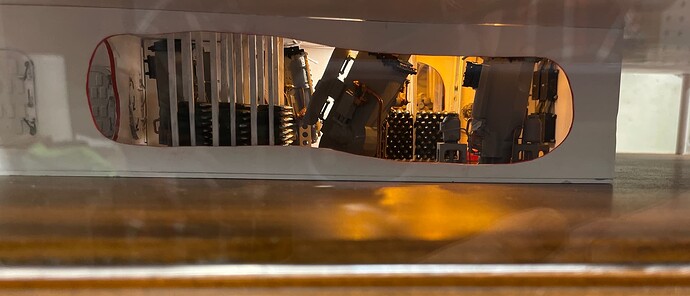

That was today’s panic moment. With the tape off, the lighting was excellent.

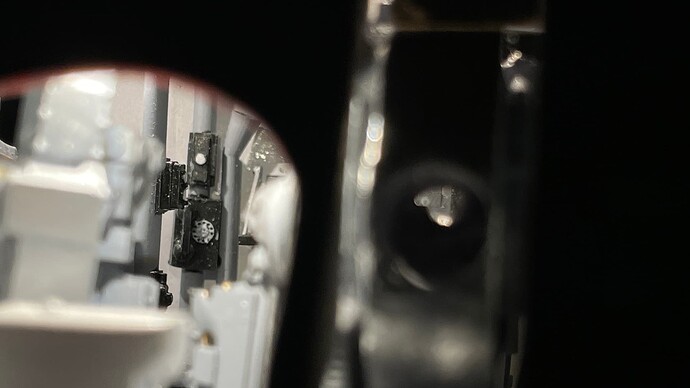

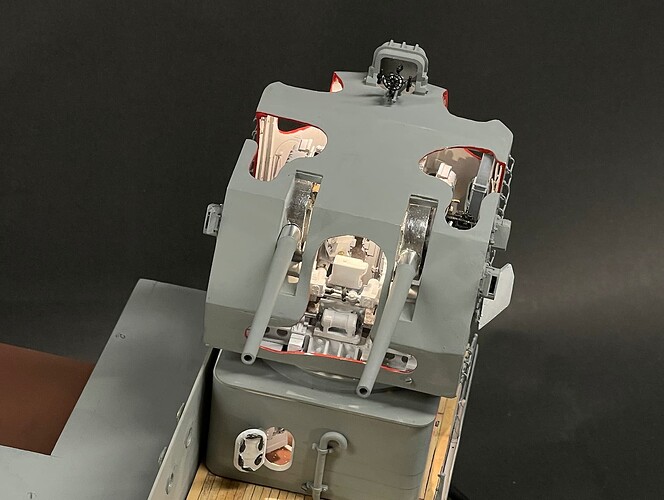

Looking from the side you can see the front faces of the those complicated hoists which I spent so much time designing, printing and painting.

I took some more pictures with the room lights dimmed and bright to see how it looks. I’m not all that happy with the light leakage at the UHR’s roof joint. With the bright lights inside I can see that it’s caused by the vertical beam still being a little too long and keeping the roof from nestling down. Nothing I can do about this now. I kept shortening them, but apparently not enough.

All that was left was the railings. I didn’t have much time before my 5:00 quitting time, but I got them strung. I only have to trim the excess E-Z Line and paint. The stanchion holes are sized perfectly and I didn’t have use any cement. They were all a nice push fit. I broke one turnbuckle, but I had already strung the first line and it was all CA’d so removal could be a problem. I am going to live with it. Actually, you probably would only need turnbuckles on one end of the run.

I took this image looking through the cutaway at the GH front and took a picture of the telephone dial. I sent the image to Ryan and he wondered why I didn’t paint in the numbers. He’s a kidder…

On Monday, I finish the railing and go around one more time doing a any cleanup/touchup and the model will be finished!

The AV program is done too. I have to purchase the digital picture frame to run it. Since I now have some time, I can order it, install the program and debug it before delivering it to Ryan.

I will take some beauty shots next week that will resprent the As-Built Builder’s Photos.

I will do a final wrap up and “Lessons Learned” discussion when it’s finished.