I never saw that kit. Do you have any more information about it?

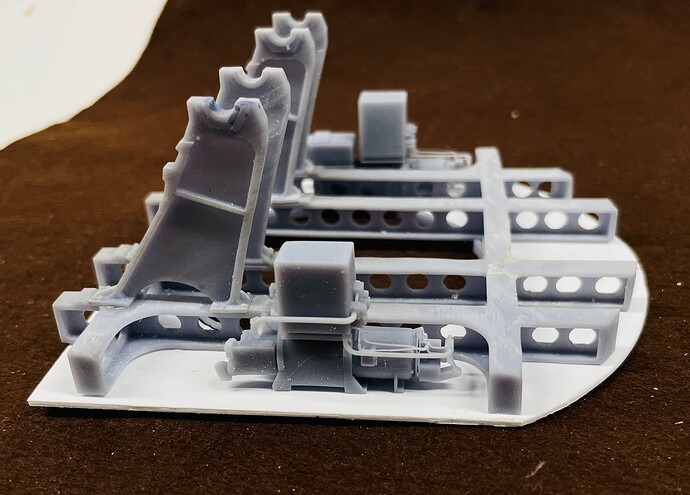

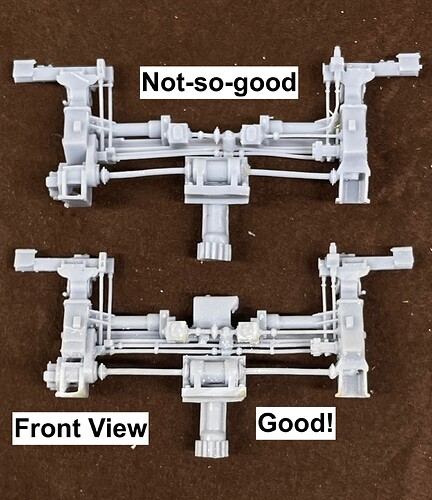

I printed the more robust ladder rungs and I’m pleased with the result.

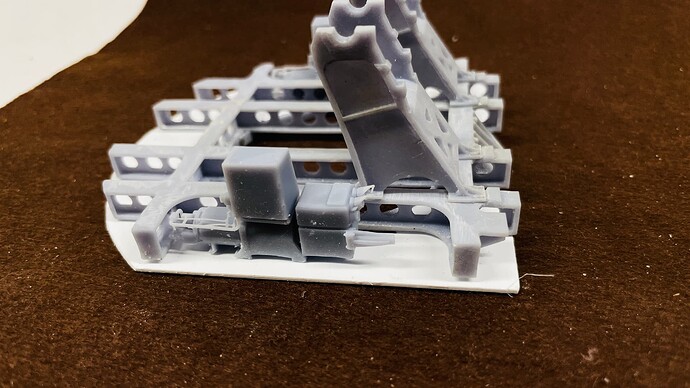

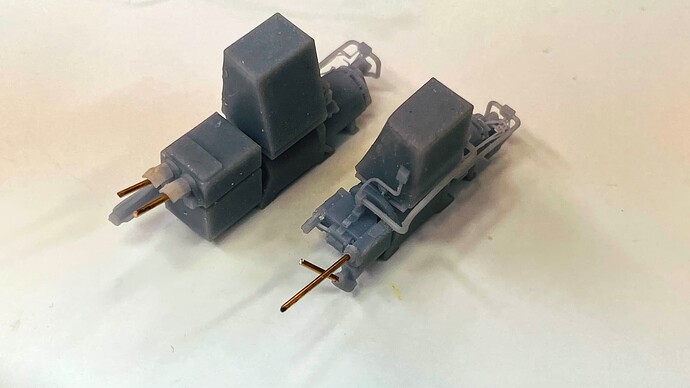

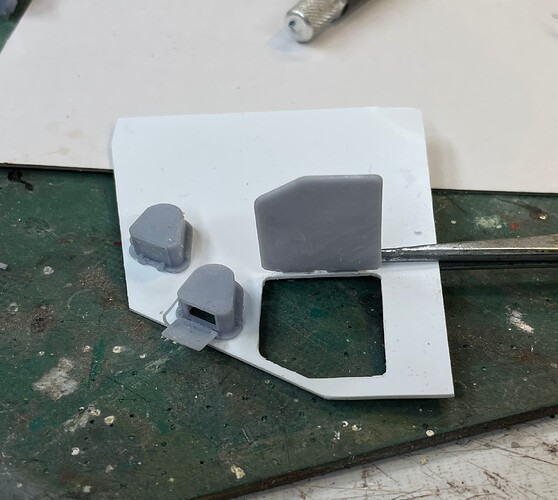

This shot was taken during the removal process. I’ve found that using the flush cut tweezers thing that MicroMark sells seems to work pretty well in snipping tiny supports. I also used a very sharp #11 blade. The blade only works on parts that ARE NOT post-cured.

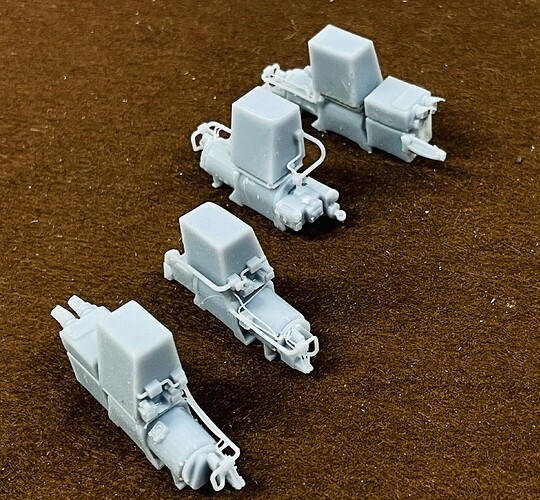

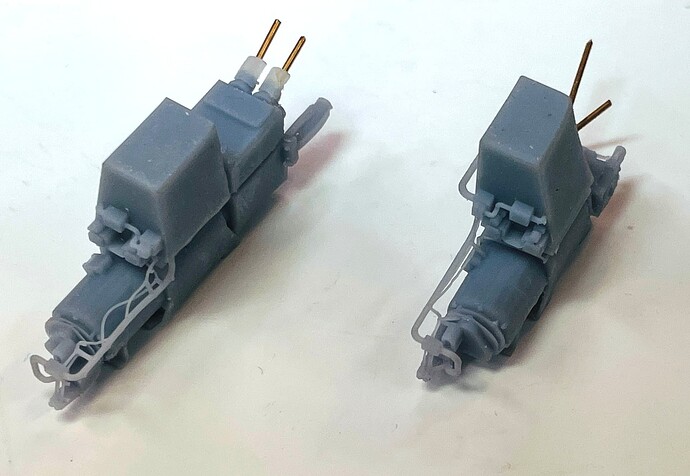

And here they all are ready to go under the UV lights for post-curing. In their native state, they were too flexible to be useful. That flexiblility is imparted by the Siraya Tenacious flexible resin in the mix. The extra girth really added survivability to these delicate parts.

I was at the local hobby shop and picked up the scale I-beams and some 5/32 angle stock to build the gun house.

I’m in a highly unusual situation. I am working five projects at the same time. I usually work one at a time, but not now. I have the turret project running concurrently with the Takom 1/35 AH-64D Apache. I thought I’d get the latter completed in time for my modeling club’s regional exibition, but probably won’t and will enter some of my previously built models instead.

Speaking of the show (in September), I slated to make two 45 minute presentations on the 16" turret project, the title of which is: “21st Century Modeling: Traditional Skills+3D CAD+3D Printing” That’s project #3.

Project #4 is creating a small n-gauge train layout for the window of the Newtown Hardware House in Newtown, PA. This commission job stems from my creation of an O’scale version of this iconic Newtown building that was a hardware store since its inception in 1869. The store’s owner was so impressed with the fidelity of the build that he asked if I could do the RR. I just happened to have built such a small layout with the grandsons 12 years ago and will modify this layout for the store. I’m making an n-gauge version of this model. At that size, I can 3D entire walls in one go, unlike this one where I had to have the walls laser cut.

Project #5 is helping a good friend and fabulous modeler, Chris Bowling, refurbish a 1:15 scale model of the NASA Space Shuttle. I’m tasked with creating the artwork for 1:15 scale vinyl wrap that will have the heat resistant tile design. I met Chris through our modeling club and his work is spectacular. We have sort of a mutual admiration society going. I’m not quite as festidious a modeler as Chris, but I experiment more and push the envelope. I’m sort of the R&D department. The model was originally built by North American Rockwell and will be on permanent display at a new air museum in Bowling Green, KY.

So if tend to drop out from one project or another, don’t worry, it’s just me doing what I do.

s

s