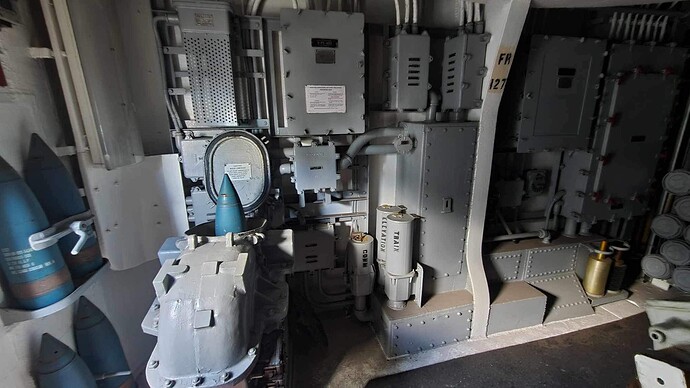

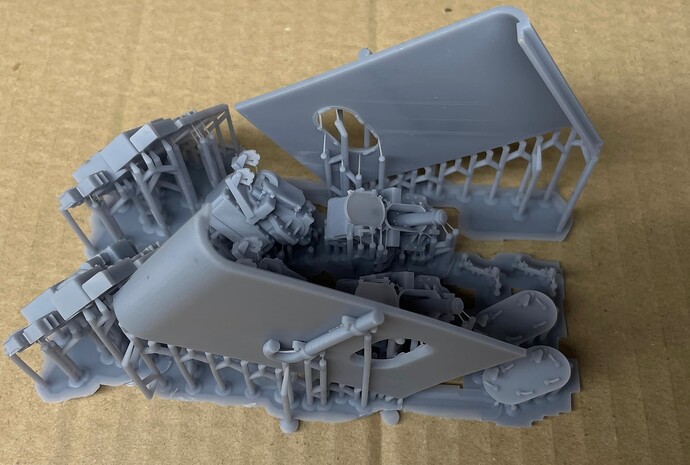

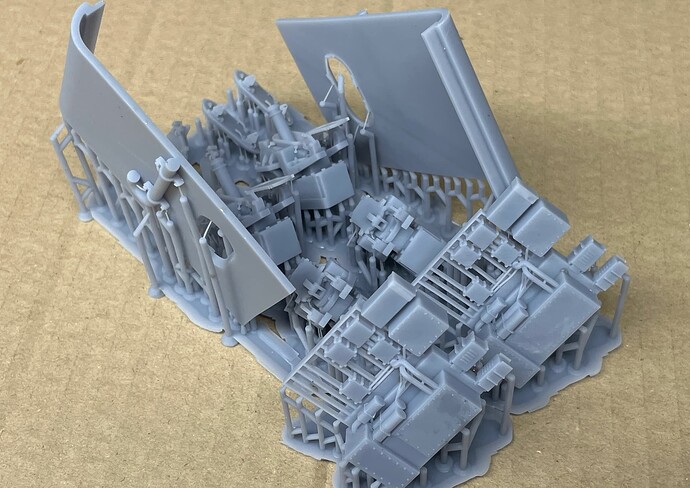

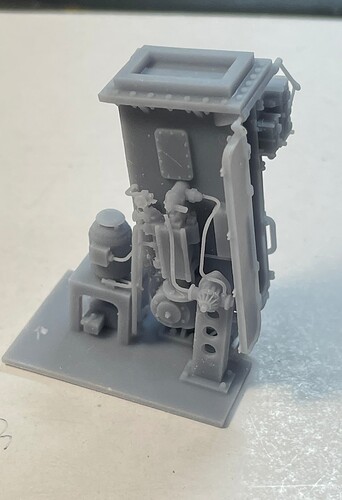

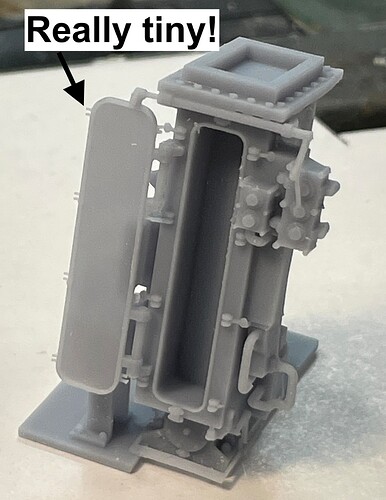

It took some extra effort to create the full ammo racks with the cartridge tanks and projectiles showing the illusions of all the ammo, but with some trickery to use less resin and make the print simpler. I got input from the SketchUp forum on how to simplify the drawings. I just pulled a huge print off the machine including all the ammunition racks for the Upper Handling Room (UHR). With the 3.1 second exposure, it seems that everything I want to print, prints, and prints perfectly. Moreover, all the tiny features have strength that I didn’t think was possible. Case in point. Get a load of the Gun Captain’s fold down platform. The side supports are really fine, but strong.

This post is going to have a lot of varied stuff.

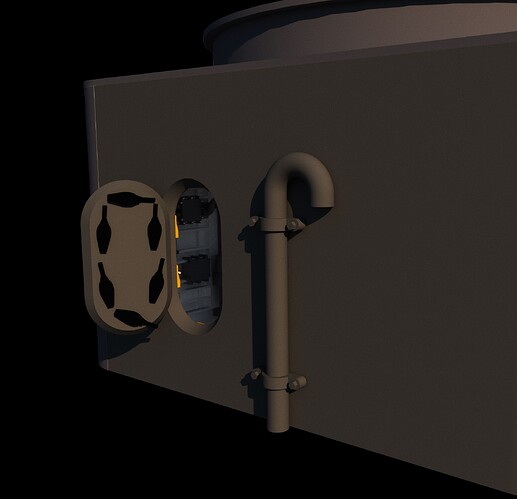

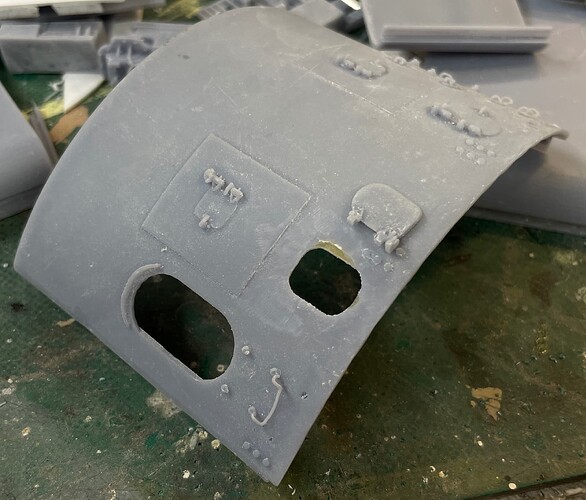

I drew this part so the back frame was curved to conform to the curved rear wall and this worked nicely.

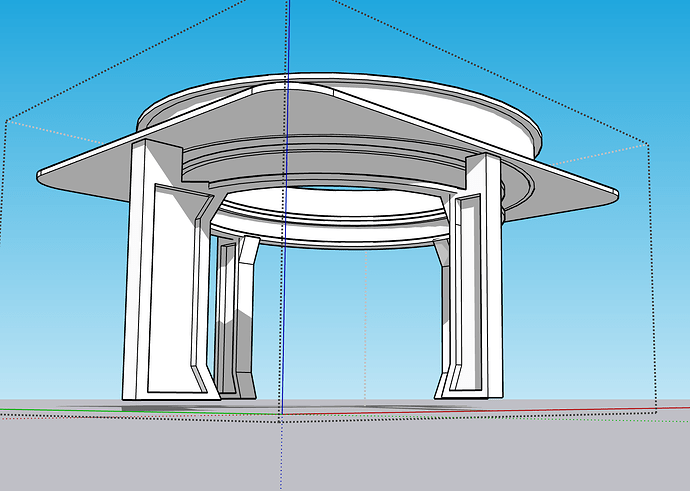

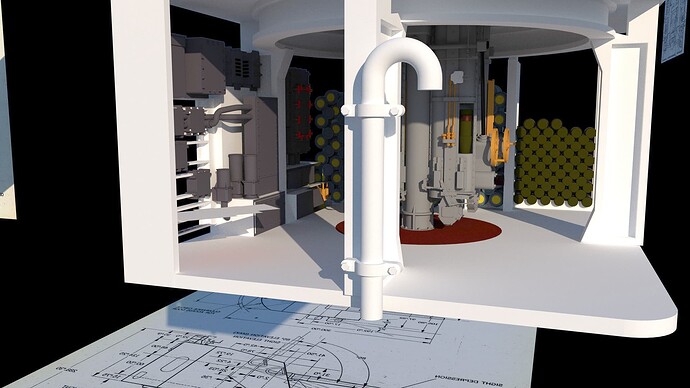

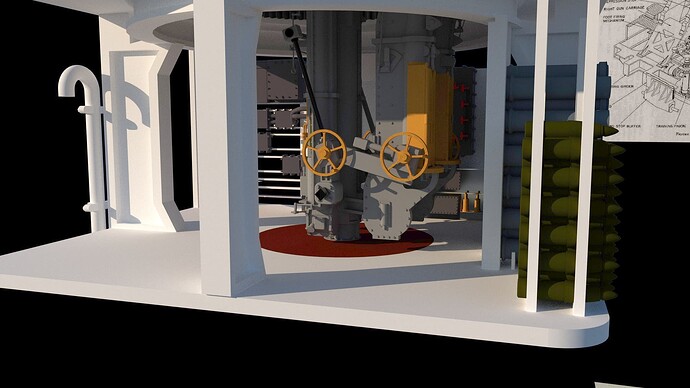

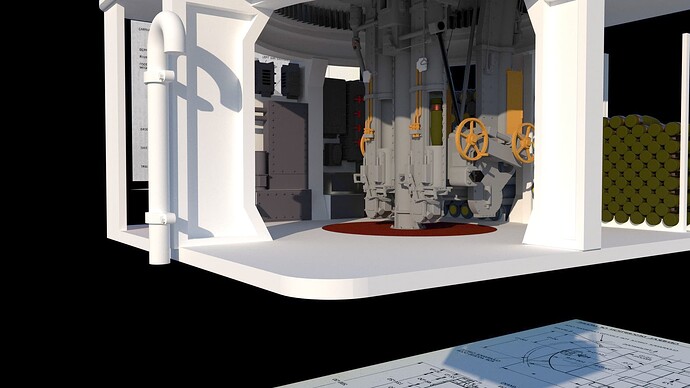

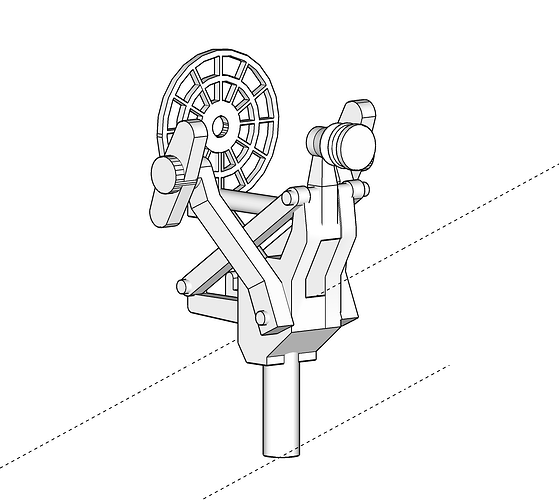

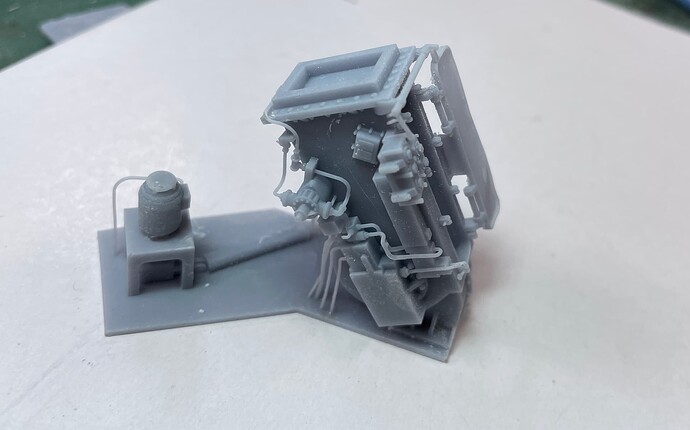

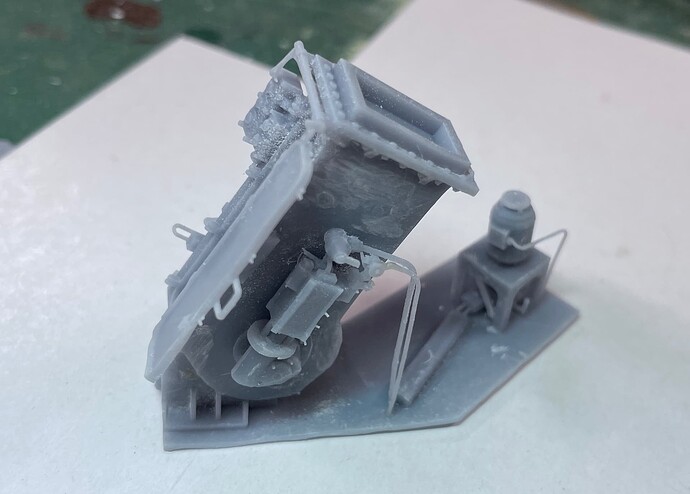

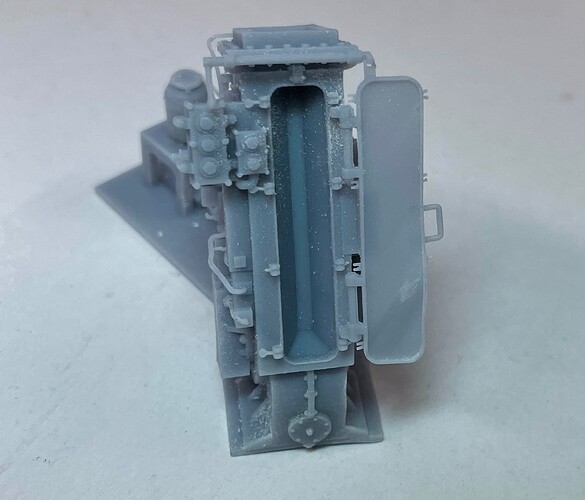

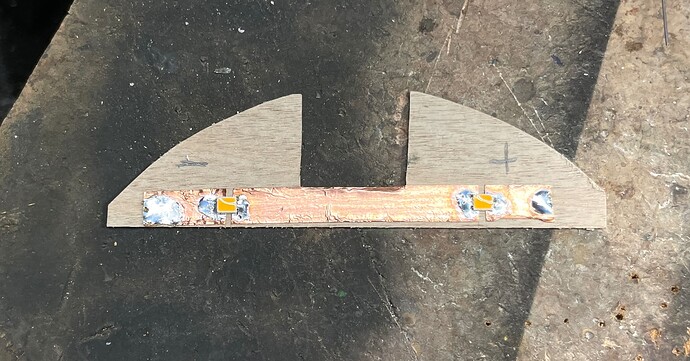

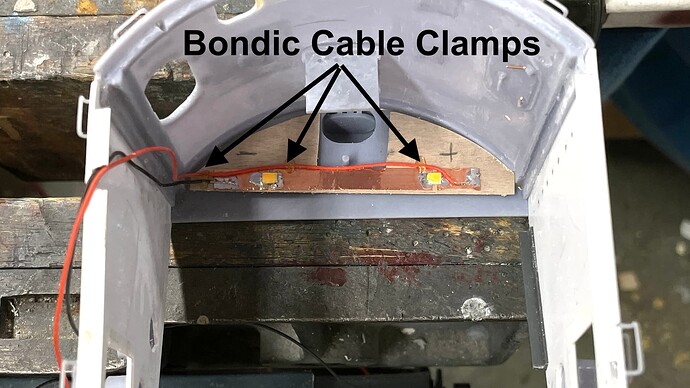

I drew and printed the massive support girder ring that holds up the massive weight of the entire rotating structure. There are form legs that support the ring and take the load into the ship’s structure. The walls of the UHR doesn’t actually support the gun house. I chose to draw and print the ring and legs integral with the UHR roof and the armored ring that surrounds the actual base. This includes the weather seal ring at the top. This was I was ensured that the ring would be centered with the rest of the structure.

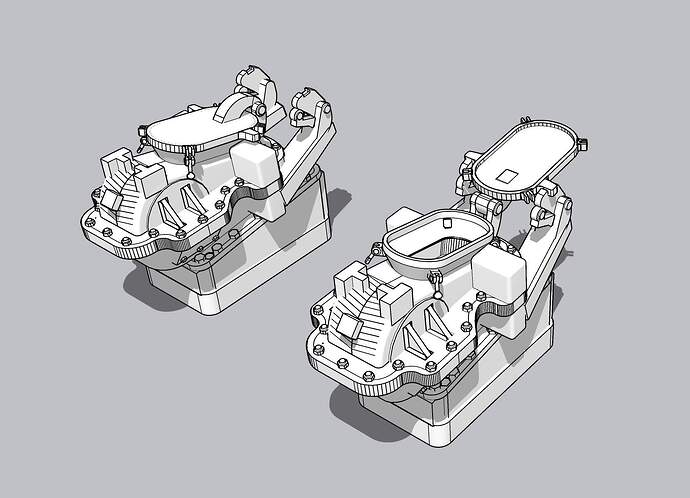

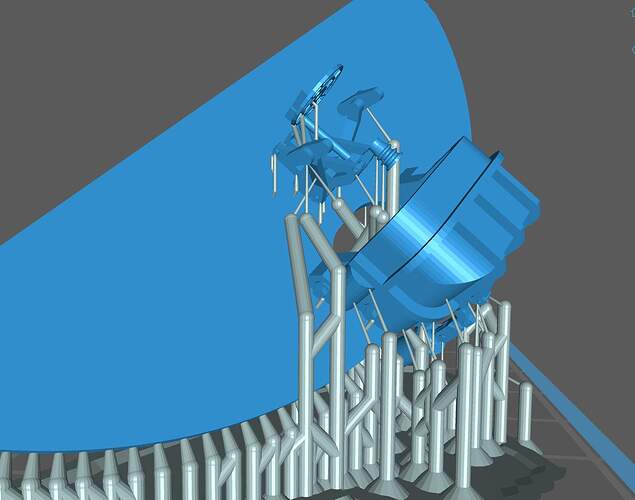

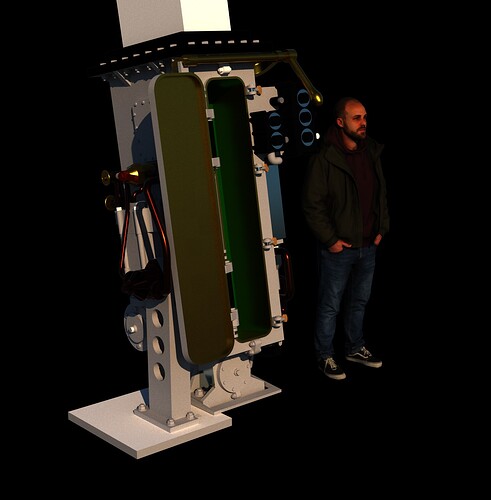

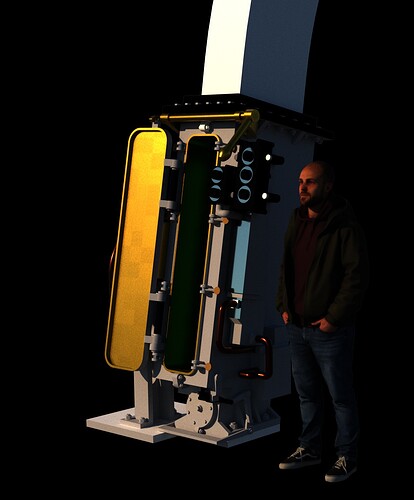

Here’s the drawing:

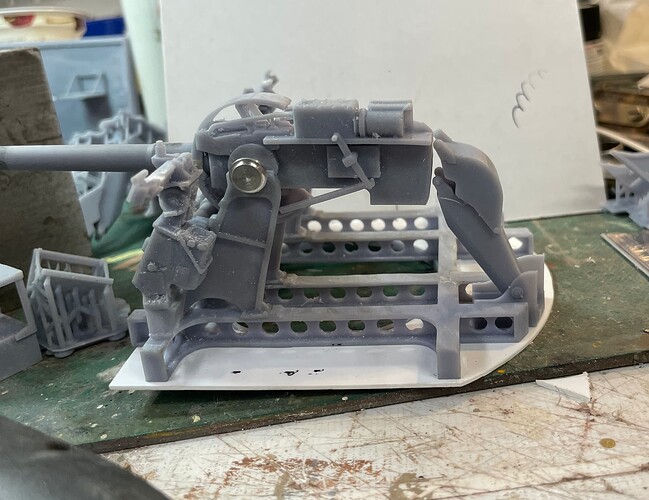

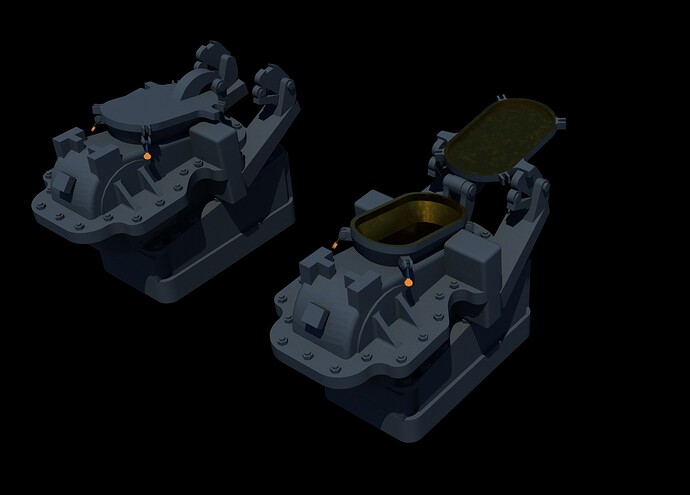

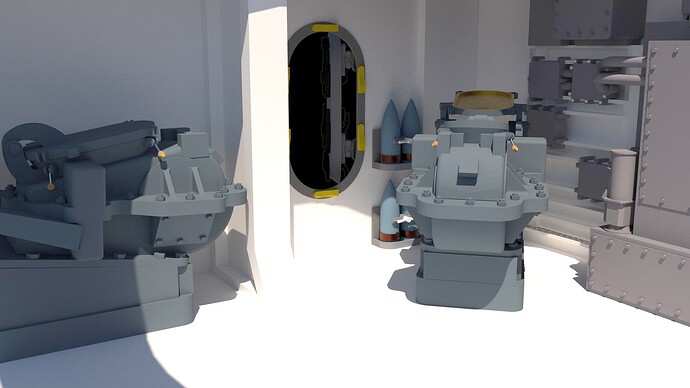

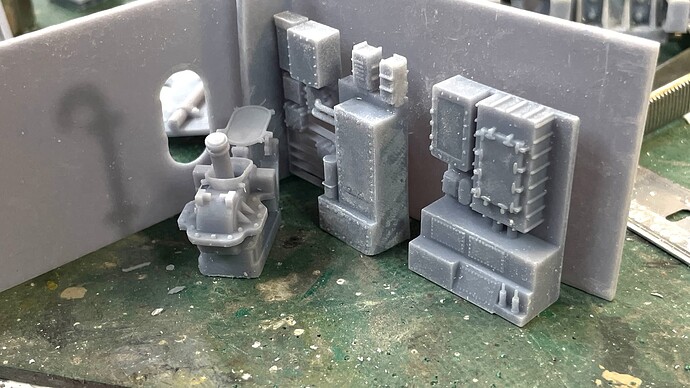

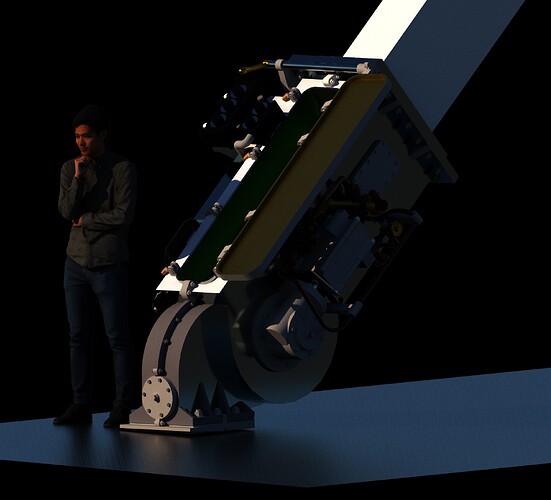

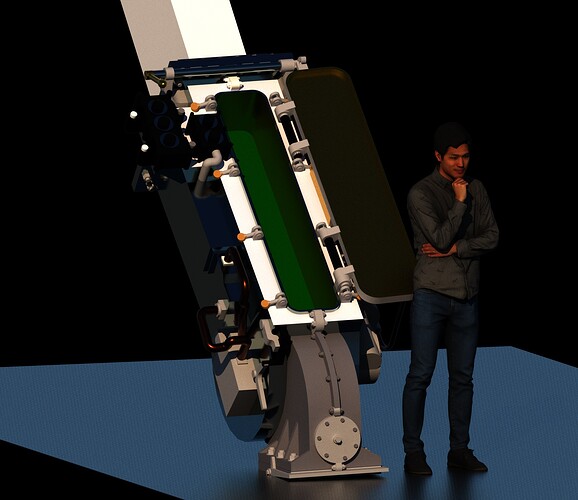

And here are several shots showing it in a test assembly.

I’m thinking that instead of cutting away some of the structure, I’m just going to leave the front wall off.

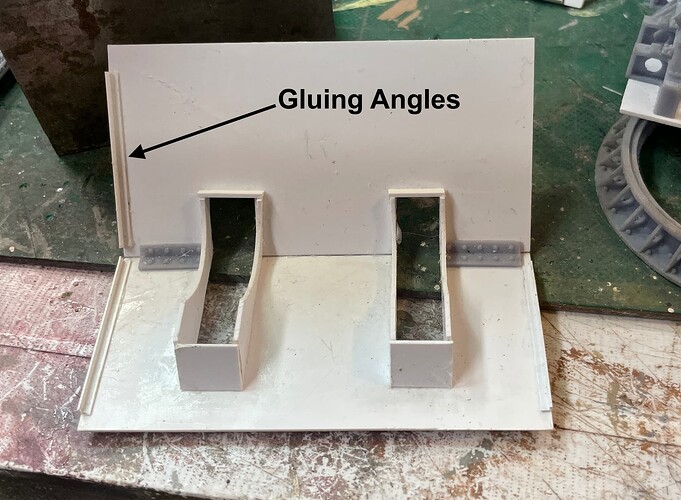

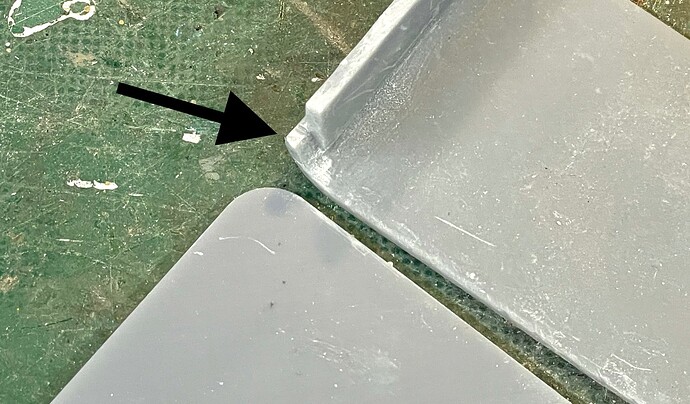

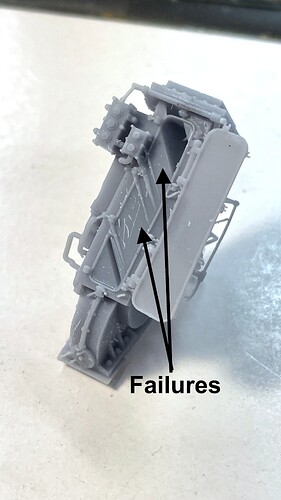

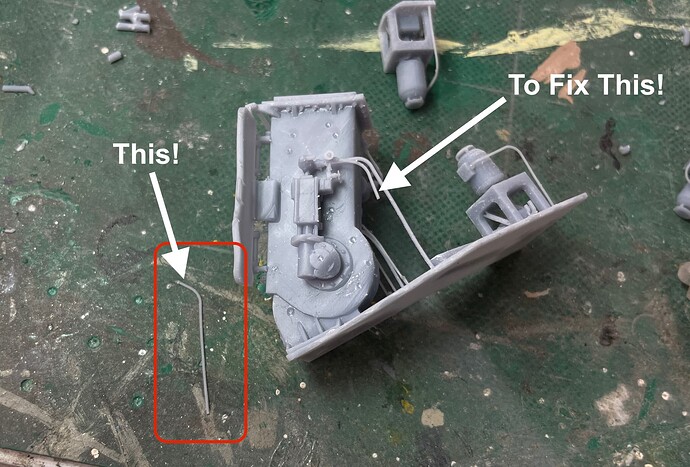

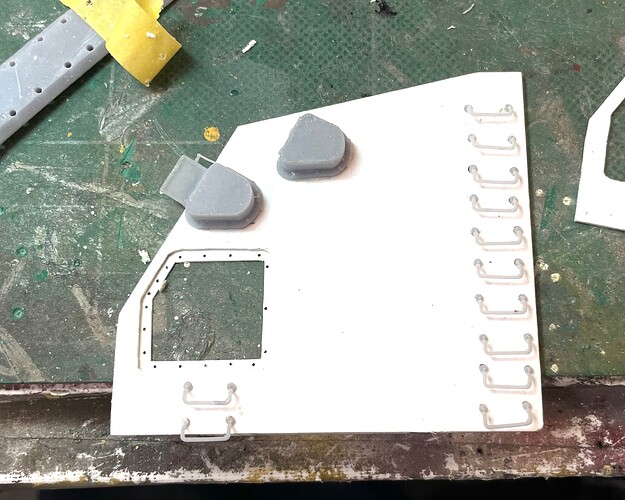

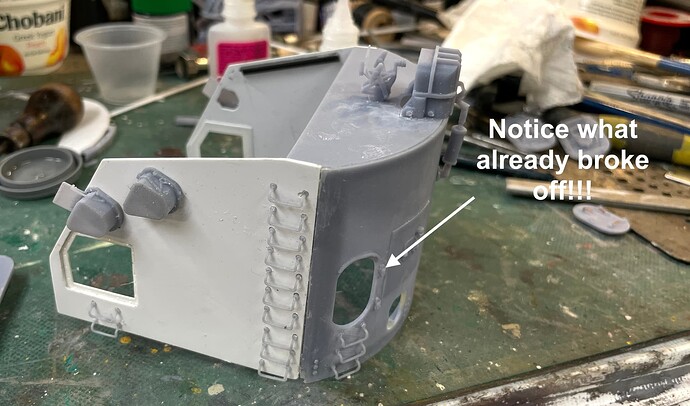

While many of these parts were in various stages of printing, cleaning and post-curing, I was getting to work on the gun house shield. I thought I was being smart by pre-installing the angle edges that would provide more gluing surface. Unfortunately, my first go was wrong. This was it.

It was wrong because the upper surfaces go inside the edges of the right and left walls. However, I had them flush to the edge, not leaving the single material thickness needed for the proper joint. Happily, the ABS angle pieces, don’t weld well to styrene with normal styrene liquid cement and I was able to pop them off. The bottom edge angles DO glue flush to the bottom edge.

Instead of fussing with the spacing I just glued them on the roof pieces flush with their edges, which, in this cae, was the correct way to do it.

I had printed some angle pieces to hold the roof pieces at the proper angles. I also finally cut the front gun shields. These were tricky piece! There was no way to really understand their shape and how they interact with the rest of the inner structure. I made them a little longer than needed with the thought that I’d make field mods. And that’s exactly what I did.

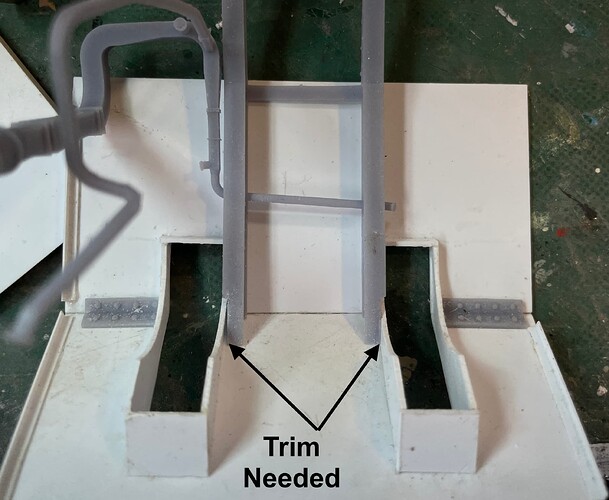

This is when I glued them to the front two angled sheets. They serve as a weather seal around the rotating gun shield and they help me join the angle pieces together. After installation the first piece I trial fit it to the gun house and found that it needed a lot of trimming. I was using liquid cement, but found it was causing the styrene to fracture. I switched to good old standby, Testor’s tube cement.

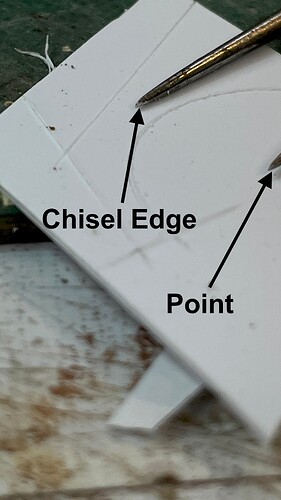

I’ve shown this in other threads, but it bears repeating. I cut circles in styrene with a specially modified machinst’s dividers. I sharpen on point to a chisel edge that’s parallel with the circular path. I can then scribe perfect circles that can be snap cut. I find it easier to spin the part and hold the dividers stationary since I can keep it at a uniform cutting angle.

This closeup shows the chisel edge.

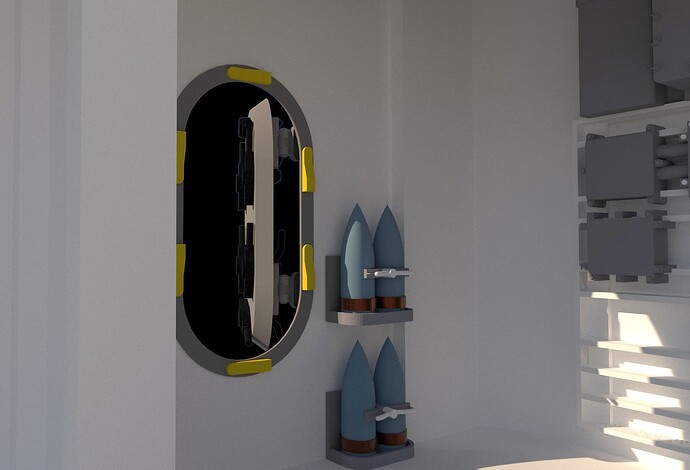

Another detail that needed work… I found that when the access doors are opened, they are swung all the way open. I had originally shaped the hinges for a 90º opening. And I wanted to have the screw holes empty and have a inner edge of the hole. I used some thin styrene sheet with 0.020" holes drilled in the matching pattern. The illusion is a good one. I’ve printed new doors with the hinges fully folded and no bolts.

The outside joint needed some filling and sanding. This was nice, normal, old-school model building job.

I drew and printed the last details for the gun house; the cartridge discharge chutes, and the cam brackets that sit at the back of the gun pan. With these parts everything in the gun house is printed and ready for paint and assembly.

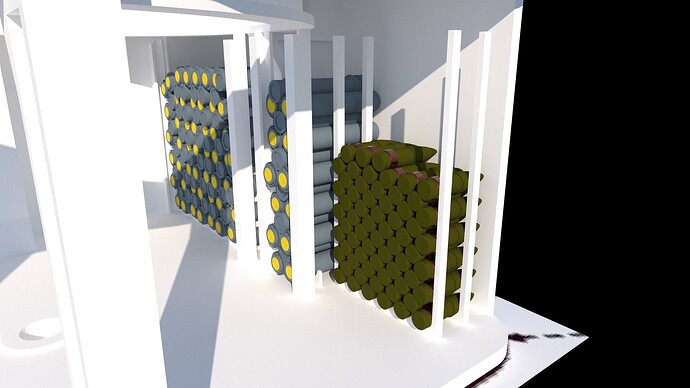

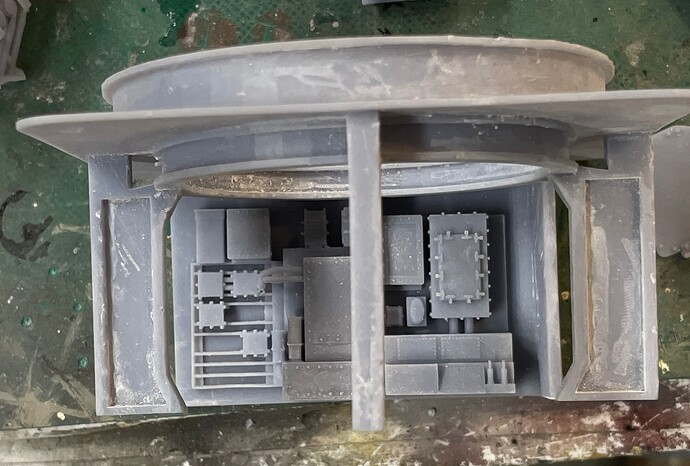

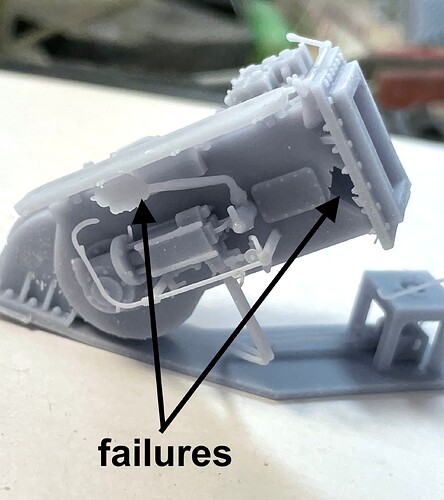

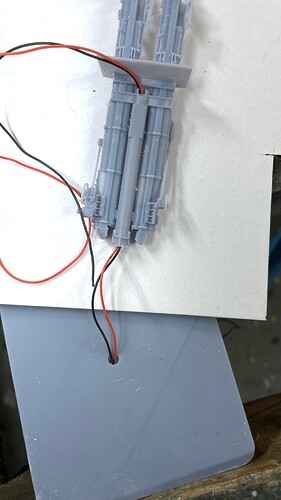

The next up was the ammo racks that line the rear wall of the UHR. After trying different methods including those offered by readers, I was able to draw and print the 80 cartridge and 20 cartridge arrays for the powder tanks, and the projectile rack. In each case there is a big chunk of plain resin so the printer didn’t have to cope with all the intersections therein.

This is what all of this looked like in the slicer. I was confident that it would all print successfully.

It did print perfectly. In the cleaner now.

Lastly, I fit the ceiling beams into the now-constructed from glacis plates. It needed a scosh of trimming to fit. I didn’t allow for the over-scale thickness of the gun seals.

Here’re all the racks for the UHR. I print doubles of everything, I only need one of each type, but experience tells me that all kinds of things can happen before the model is finished.

Tomorrow’s Saturday, so no work in the shop on the weekends. So all have a nice weekend. Don’t do anything stupid shoveling snow, it you’re in an area where it going to hit and I’ll see y’all on Monday.