Hi model builders,

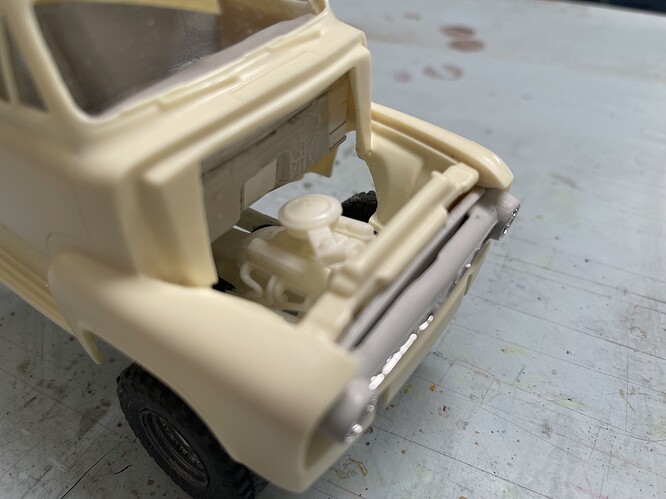

I have made progress on and largely finished the bed.

@Johnnych01, you’ll like this - the bed is made up of evergreen and the lower body parts of a Scania tractor. I mention this, because of your comment above. My sense is that if you decided to go for a project like this, you probably could - the idea being most truck chassis/suspension have a few common pieces, same with beds, engines etc.

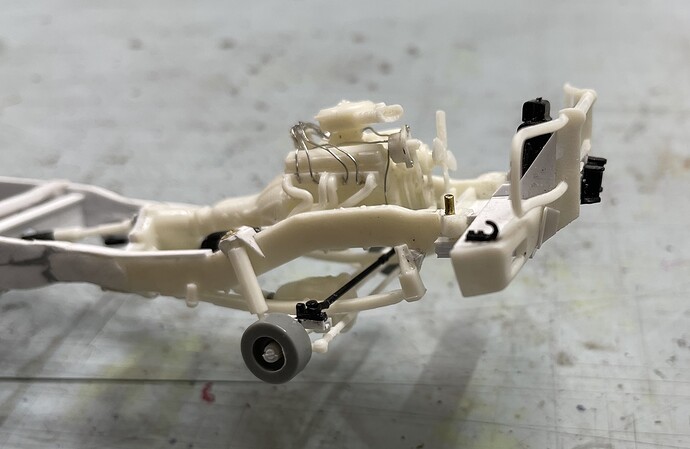

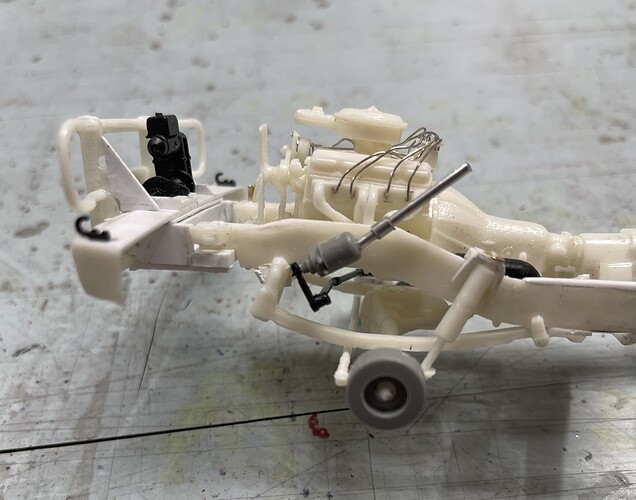

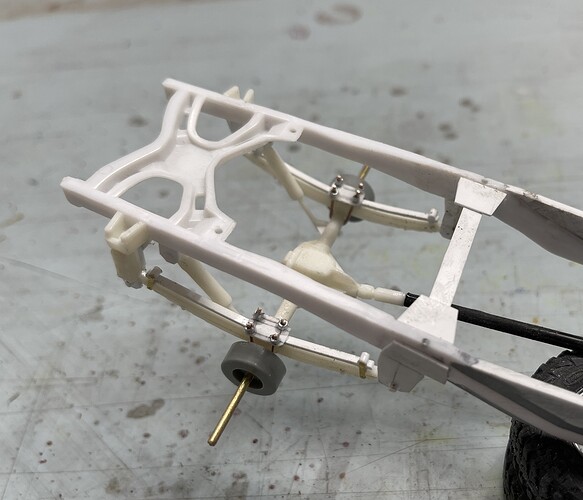

While I like to eventually add lots of detail, the first tasks usually focuses on what seem to be easy steps, but I usually struggle with them: Getting the frame straight and level, locating body connection points, and keeping axles perpendicular to the chassis. It’s worth the struggle to get these fundamentals done right, even if you have to tear them apart a few times in doing so

Like anything with some practice, you can work these up to look ok. Or, unhappily, you can usually see pretty quickly if it doesn’t! And, once you’ve built a few things that don’t look right, it gets easier to take out the saw or knife and rework whatever didn’t turn out as hoped and get it fixed.

I think getting axles centered where you want them relative to the wheel opening and one another is real headache. In addition to getting all four or six tires sitting on the ground, getting them to look correct inside wheel wells can be pretty frustrating, but essential - if they are wrong, well, everyone can tell!

Funny thing is no matter how much time you might spend getting things lined up, you can tell immediately if it’s wrong!

OK, on we go:

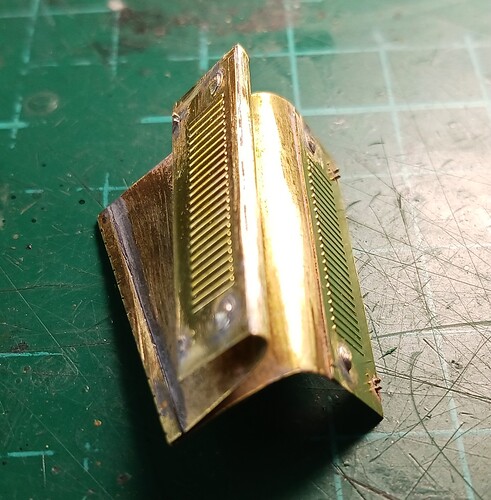

I decided to make this into a welder’s rig. It was going to have a service body, so why not specialize it a bit? You can barely tell in these picture, but the ends of these parts, wrap inward, which reminded me of the sweeping curves on the cab. I have built service bodies before and it is slow going, so thought this might be easier - well, it wasn’t, and took a long time to built, but now that it’s done, I like it.

Thanks for having a look -

Cheers

Nick