Dear all!

Thank you very much for following and especially for your kind comments, I’m glad to have you all along!

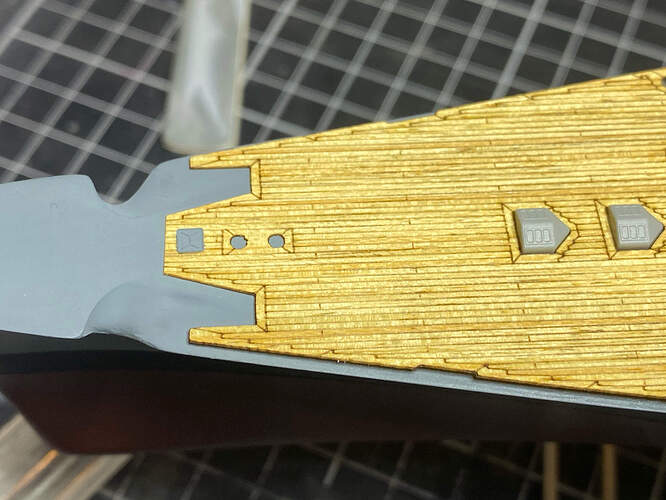

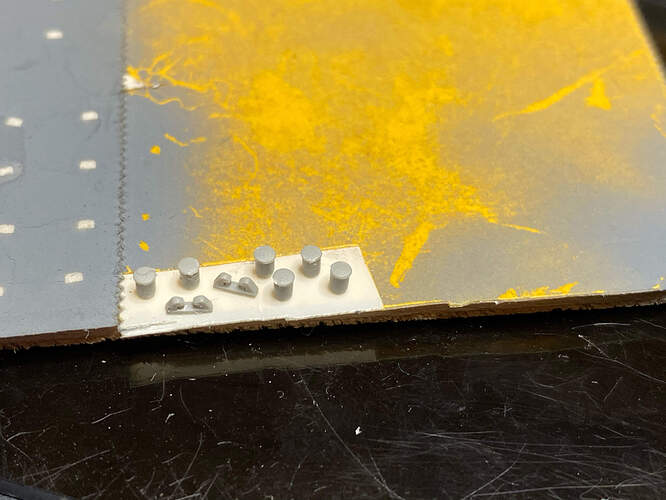

In the meantime I gave the hull a clear gloss coat for protection. It’ll all be flat again in the end, no worries…

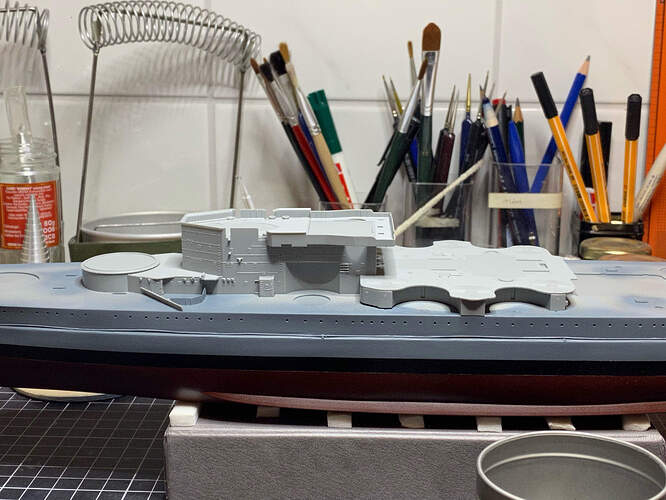

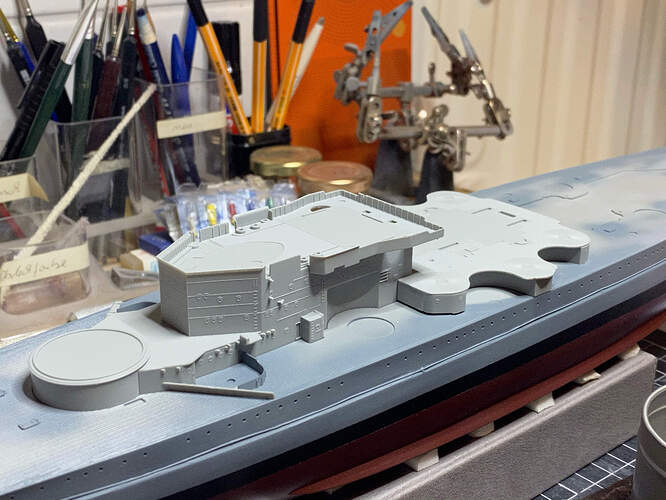

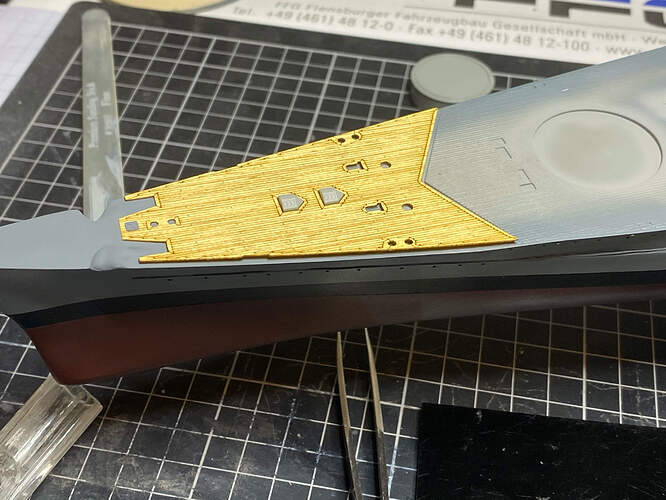

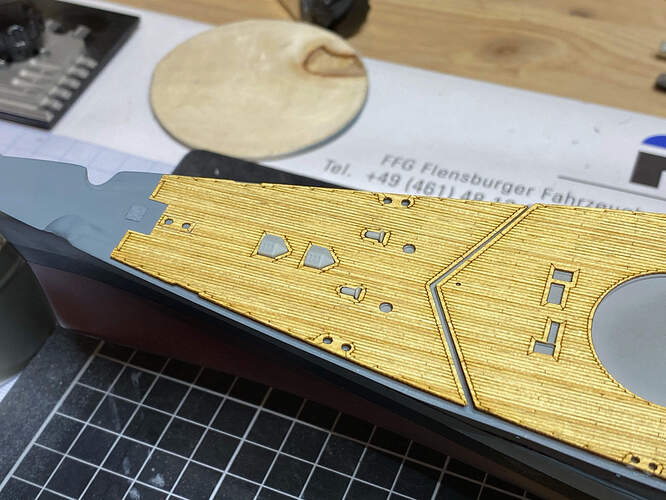

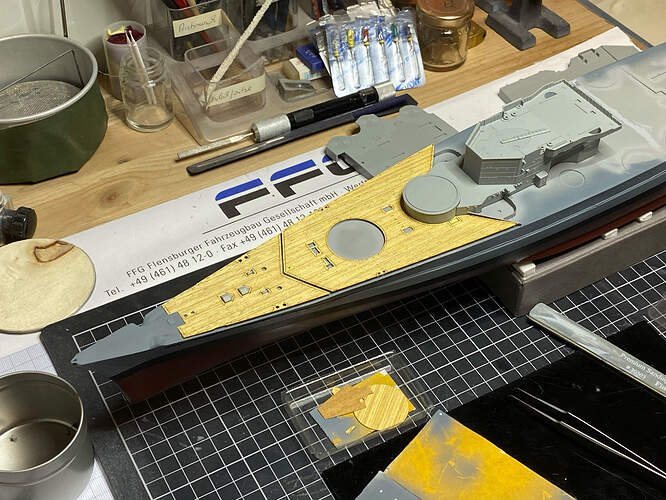

Considering how to proceed, the wooden deck should be very early on to prevent fitting issues. I had to build the main parts of the superstructure to dry fit and then get the wooden deck in place.

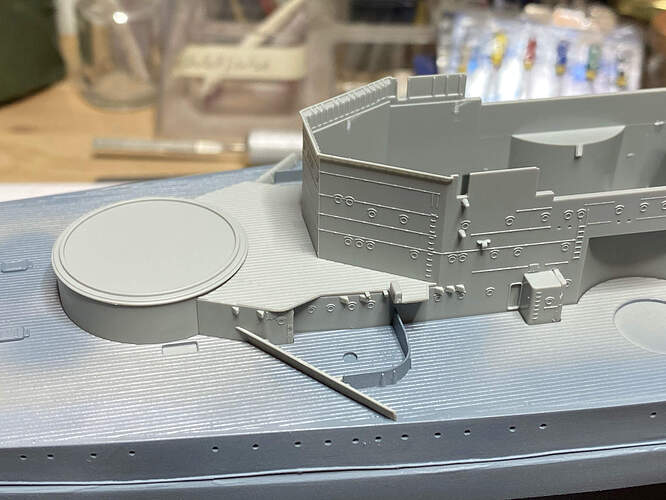

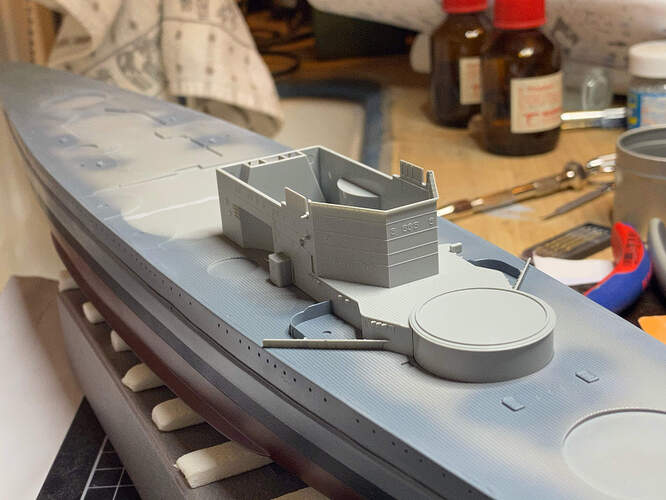

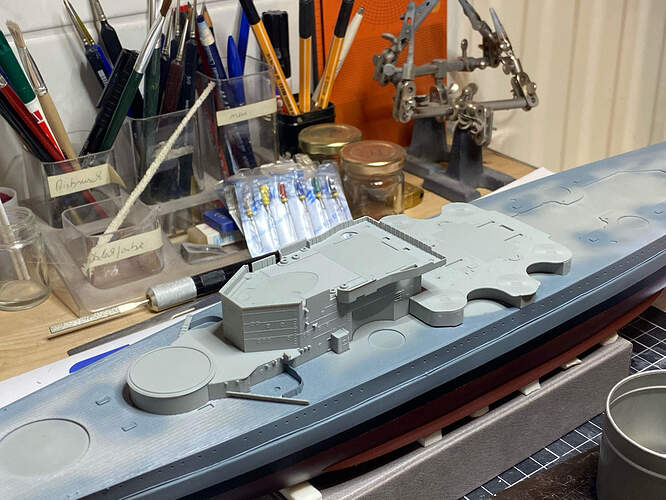

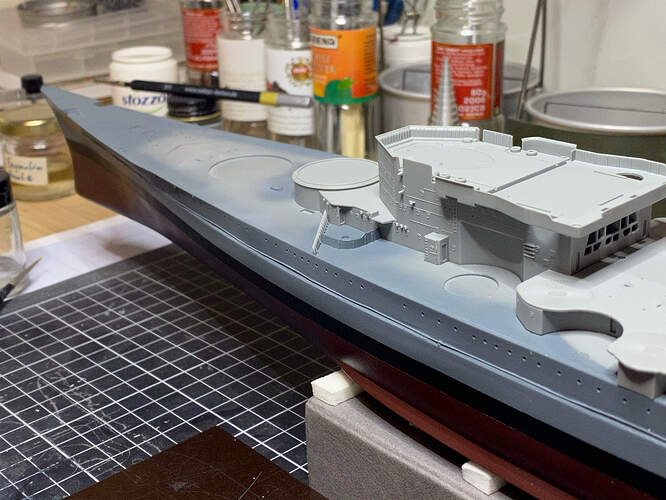

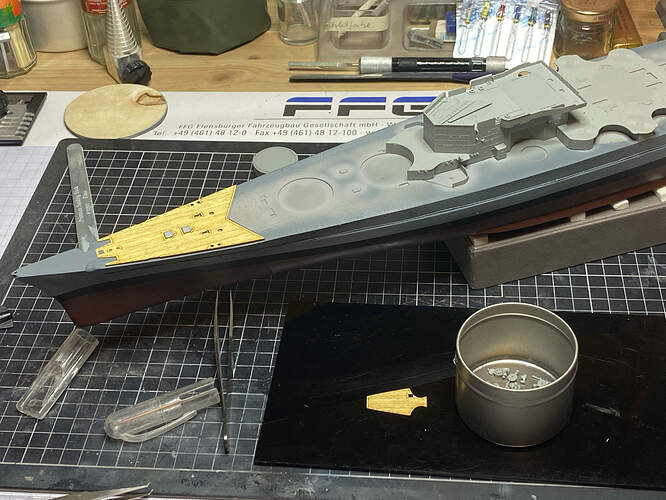

So I started to build the major assemblies that will eventually sit on the main deck. And I have to say this is really fun - fit of the parts from Dragon is really excellent, and the quality of the styrene is really nice and good to work with. Details are crisp and fine, looks really good! (…I’m sure they could have done a better job with the hull halves…)

So this looks way more than it is, it’s only the basic main parts assembled, the major assemblies glued but nothing glued to the hull or assemblies glued to other assemblies, there’s a HUGE amount of detail work waiting. And I have to find Scharnhorst/Gneisenau differences, at least the obvious ones.

With that, I realized how poor my documentation of the original is - I do have several books dealing with them, but many pictures are the same in all books, and honestly, you often can’t be sure if a picture is from one or the other, despite the author saying it is - I have discovered quite a few wrong allocated pictures in books…

I know the Kagero drawings have quite a few mistakes in them, but unless I get real pictures as references, they are as close as I can get.

Ok, pictures.

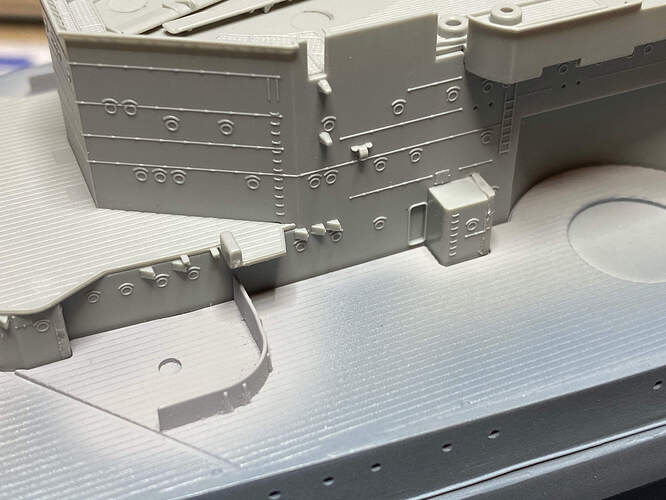

Here are the first unresolved issues - the breakwater in front of the 3,7 cm AA looks like that for Scharnhorst, but there is at least one picture that seems to show it only extending out to the “curb” of the 3,7 cm and not going all the way through. (But that would leave a scar in the wooden deck, if I cut them…have to think about that.) The little extension in front of the 15 cm may have a slightly different shape for Gneisenau - that’s from Kagero, I could not find a picture verifying or falsifying that. Would be pretty tough anyway… Well, it’s only dry fit right now, plenty of time to think and doing more research.

The deck on the forward superstructure is not glued. And even the breakwater is just a dry fit - that it sits so tight shows the quality of the kit.

That’s it for now, thanks for looking in,

Cheers

Jan