Hi all,

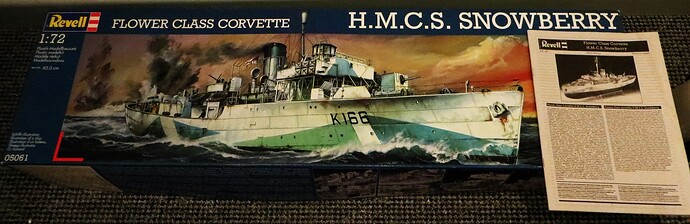

For Christmas SWMBI (She Who Must Be Ignored) treated me to the Revell 1/72nd Flower Class Corvette.

I remember seeing this, as a callow youth, in its original Matchbox guise, and though I coveted it, at the time it was beyond my meagre pocket money.

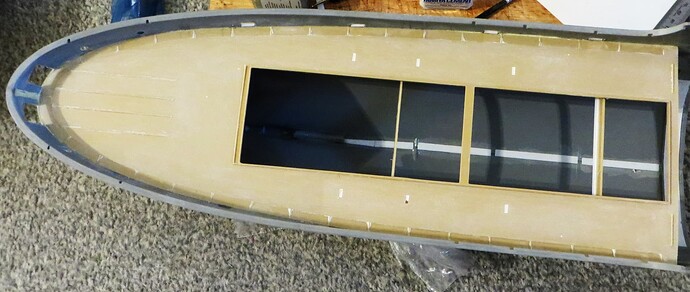

I’m not typically a builder of floaty things but really fancy having a go at this one. My initial thinking is to try to repurpose the kit as a Royal Navy Flower, if I can find out what the differences are. The idea is to then upsize an idea I’d previously used for the ‘Inaugural Railway Campaign’ started back in 2021 for an A4 sized 1/72nd quayside diorama.

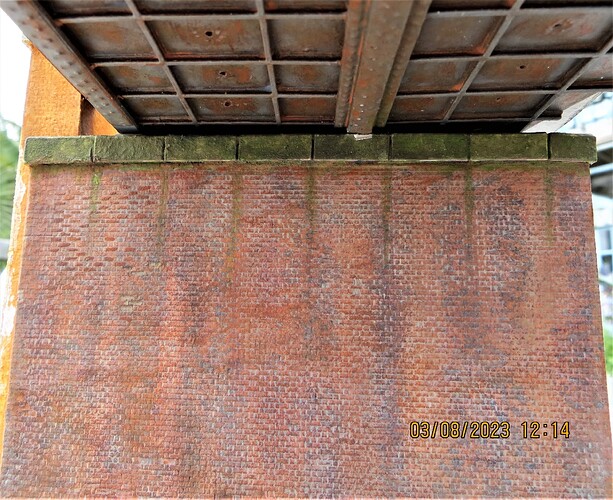

Below are a couple of images of the original diorama (more images can be found in the Inaugural Railway Campaign build).

The corvette will be moored alongside the quay.

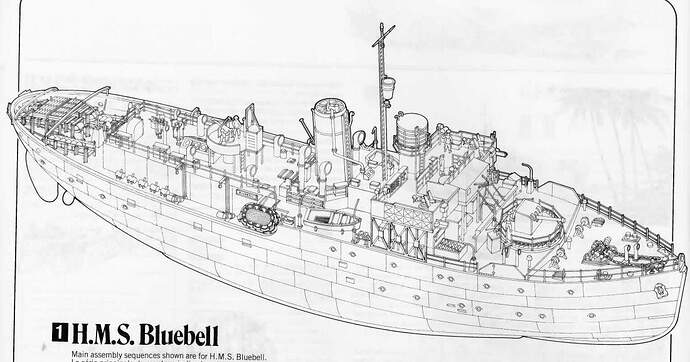

Being a shipbuilding novice means I’ll probably be asking a lot of dumb questions as I progress throughout the build.

Being both lazy and tight means that much of the vessel will be built OOB, the general exceptions will be relating to any changes needed to achieve a Royal Navy version.

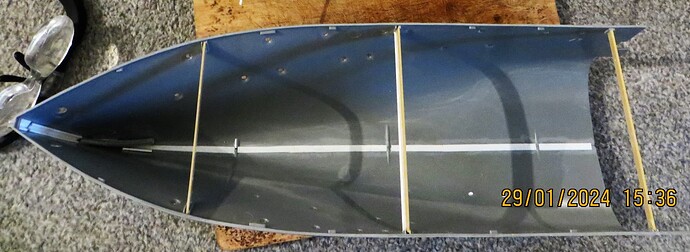

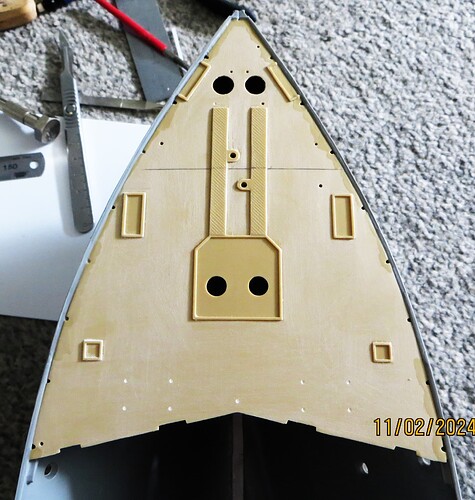

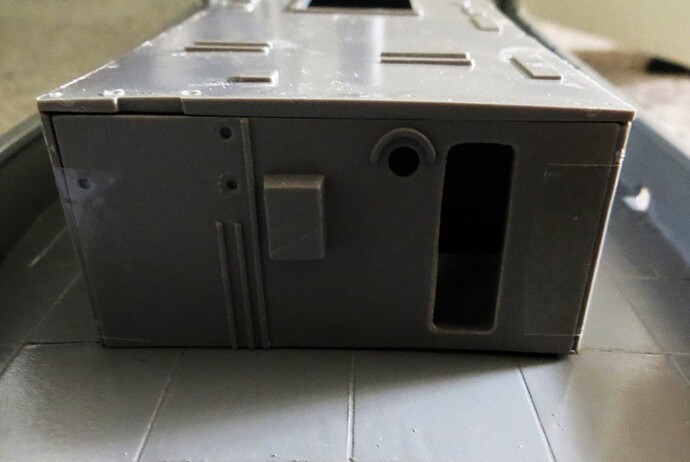

I’m starting with the hull which, I presume, will not need major work, however, the bow of the model looks a tad ‘blunt/bulky’ compared with some of the images I’ve seen online. It might just be the angle of the images, but should the bow be ‘sharper’?

Any, and all help will be greatly appreciated on this one.

Cheers, ![]() ,

,

G