Hello hello once again guys, I come to you with yet another conundrum…

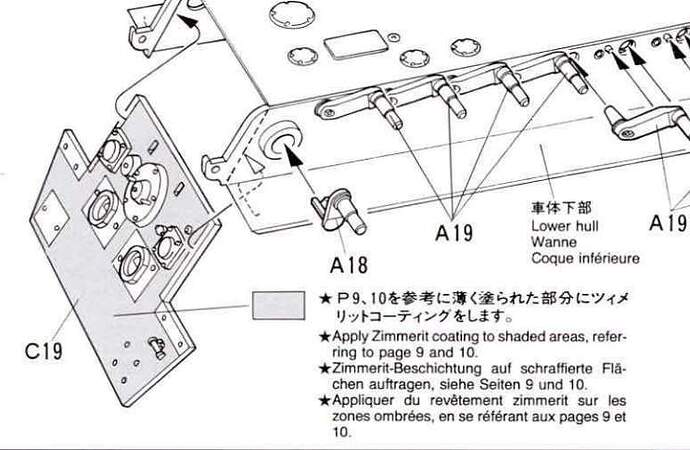

I am currently in the progress of building a spare scrap Tiger II model (Tamiya), because I want to practice both Zimmerit and 3-tone camo on it before I need to do it for real on my German tank models, and I’ve never done either cuz I’m still very much a newbie

So I bought myself zimmerit paste and zimmerit tools

But when I got to the point of needing to apply the zimmerit, it was a catastrophe. I couldn’t apply the zimmerit in a nice even, or hell, even consistent layer. It just smeared and blobbed all over. I tried to apply it with a hobby knife first, than a popsicle stick, then an actual kitchen knife (like you would peanut butter), but nothing worked, it just plopped and smooshed and was horrible.

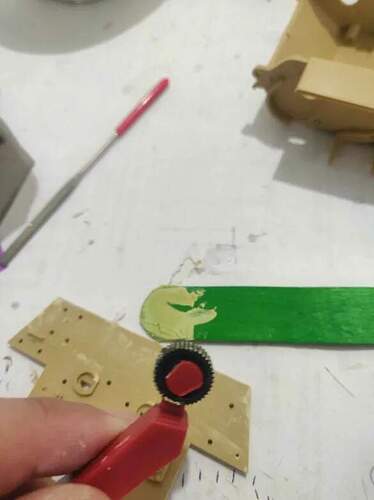

Now I figured it doesn’t need to be a nice even layer, when I use the zimmerit tools, they’ll work it out and spread and push aside the excess when I use them, right? No, they worked horribly. I tried the roller first, and this was the result:

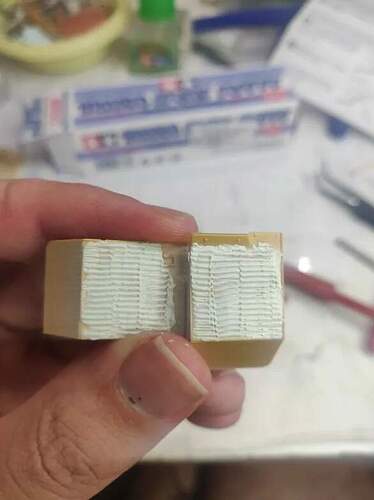

I figured it was just because the paste was too wet. so I let it dry, and also used the zimmerit press next. Didn’t help, same problem.

The zimmerit paste just clung to the tool, and it tore it off. And if I have let the paste dry anymore, it’d be like hard clay, and not workable at all.

Both my zimmerit tools are now clogged with paste

I soaked them in water, I hope I can salvage them…

Anyway, total disaster.

I have no idea how I am supposed to apply the paste, let alone how I am supposed to do so without it getting on where it shouldn’t be

By the way, if it’s of any concern, I use/d Liang Model’s zimmerit paste:

I know this entire post is a huge jumbled mess, I apologize for that

I’m sure I’m doing something, or everything wrong, so, I’d love some help and/or advice from people experienced with zimmerit paste

Thanks in advance as always!