As real work is slow, well, a guy can spend some time in the fab shop, working on this!

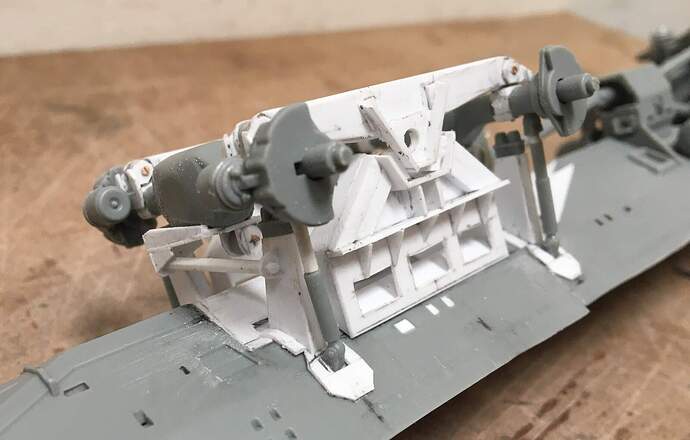

That rear end, is no picnic to scratch build. I am glad to have used that jig, as I kept it in place for a relatively long time during this process, and the results are pretty good - specifically, it sits level and the parts are square - I had doubts about achieving both.

On we go:

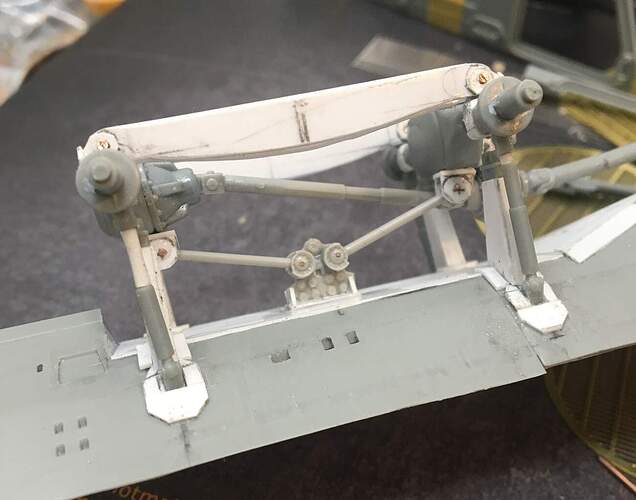

It turns out the shocks from the kit were just a bit short, so I extended them, and, added metal pins to the top and bottom - which allowed me to plug them into the hull and axles. This worked pretty well, to help keep things squared up and where I wanted them to be.

The torque arms are from the M1083. I also used pins to hold these in place - which allowed me to first glue down the central mounting plate, then I could freely tilt the arms to sit on the axles - they were then flooded with glue! Next up were those bump stops. This was a bit harrowing - as they are mounted on small towers that have a sloping base and taper inward from the hull… ![]() Despite their being firmly attached to the hull, they don’t touch the axle, so don’t help with stability.

Despite their being firmly attached to the hull, they don’t touch the axle, so don’t help with stability.

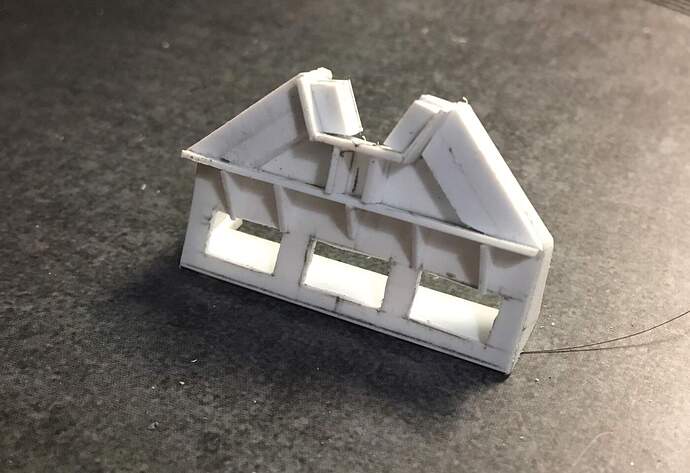

I won’t recite all that’s going on here - the key element is the structural frames for the suspension.

While Rob’s photos don’t have dimensions for this there are several very clear pictures of what they looks like, and one straight-on shot that shows enough that I was able to trace off the spacing between the parts shown in the photo, and establish some proportions and not to scale dimensions.

Then establish a few key dimensions on my build and determine percentages of distance, to allocate spacing relative to the photos. While a bit tedious, it worked fine.

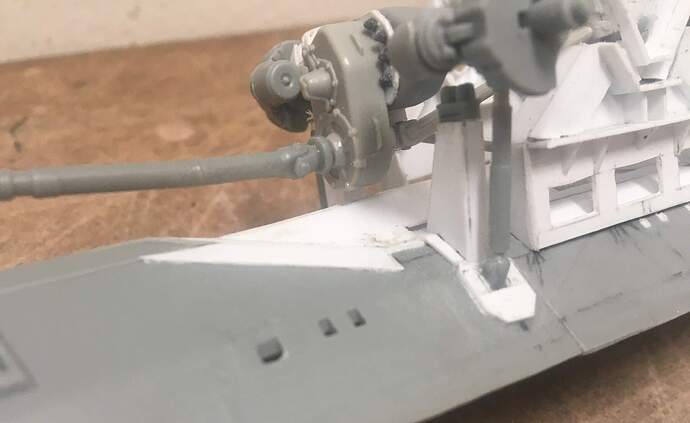

Next - I concluded that while I needed to cut the hull to get my axles to fit, I couldn’t live with the resulting flat spot, so, when this was all done, I went ahead and added the hull shape back, albeit slightly lower than the rest - in the parlance of design review, I think it demonstrates convincing realism! Unhappily, there isn’t much contrast in the photo, so you’ll have to take my word for it, there is indeed a “V” shaped hull in there!

And guess what? nobody will ever notice! ![]()

As for the truck right now:

In the lower picture, you can just see where I added the “V” hull - lol- again, not all that obvious - which I suppose is good news - the better news: This sits level and is pretty solid.

This needs some cleanup and bolt heads - they are apparently on their way in the form of some hex rod.

Next up, I’m trying to decide - cab or hood?? likely the hood -

Thanks for having a look -

Cheers

Nick