So I have a pile of vinyl tires left over from modern wheeled vehicles, replaced with resin units. I was thinking about using the left-over vinyl tires as cargo for various vehicles. My question, is how are spare tires shipped to combat or maintenance areas? On pallets? Wrapped in plastic? Loose? For instance, straight off a C-130 unto an M-923 and off to the front. I’m sure I’m not the first one to think of this, but I can’t seem to find an answer of pictures.

Thanks in advance

I can tell you that the US Army got away from being able to order tires by themselves. Now you need to order the wheel and tire assembly as one piece generally aired up so you can throw them on and go. I have seen them stacked on palettes and with the shipping label just stuck to the tire and sent by itself. it’s a little bit how many you ordered and a little bit who was working at the supply point (SSA).

Not sure when it changed, but they could still be ordered by just the tire when I retired in '17. They usually came banded on a pallet. Two of the larger tires to a pallet, four smaller tires to a pallet.

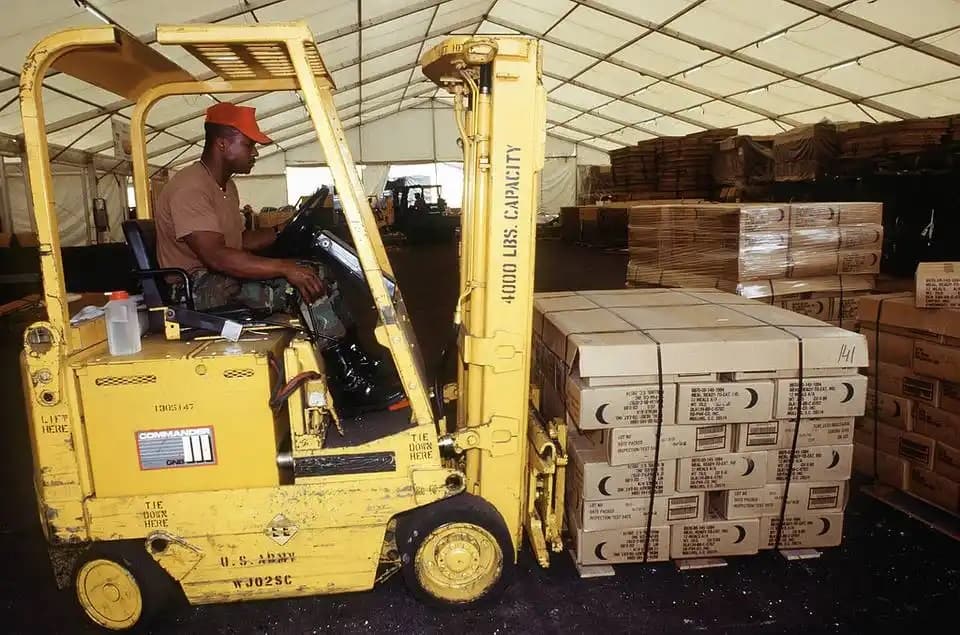

Most Army supplies (including replacement parts) came banded to a pallet to make them easy to ship and move around.

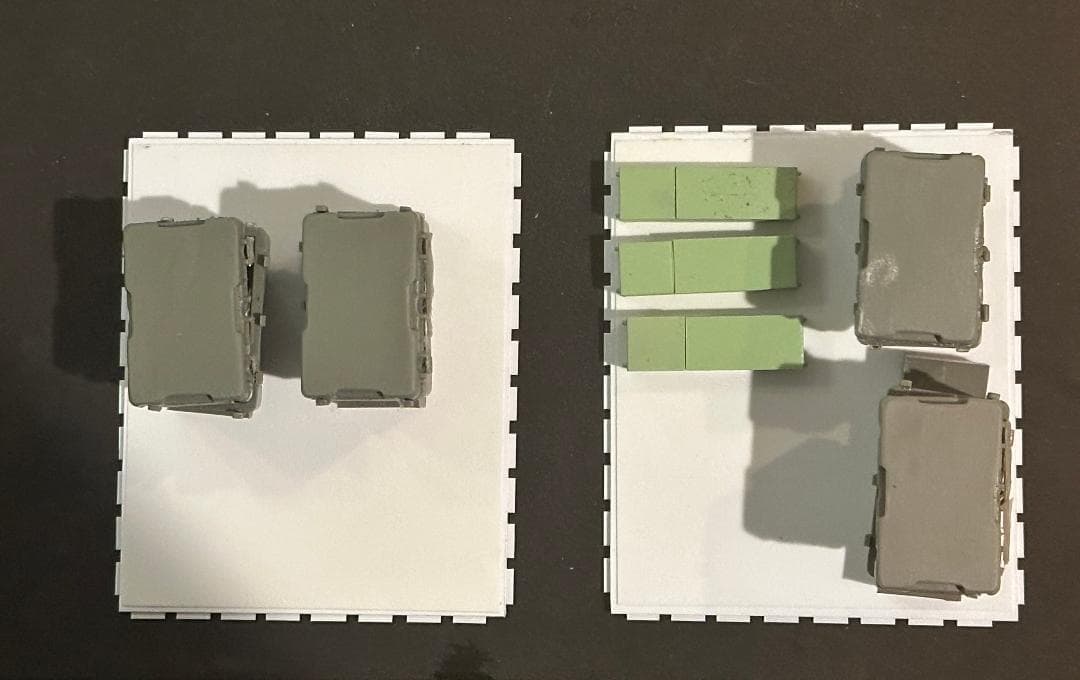

I made a whole truck load of palletized items a few years ago for a ODS USMC resupply truck/trailer combo.

I work JBMDL -DIX main store some time we have to take pallets of merchandise to the TMO at McGuire to ship to our store up at Thule AB ,one time i was there waiting to get unloaded and seen pallets with tires with the rim already mounted also of interest was was 2 pallets with a entire set of brand new

tracks for a Abrams and if anyone is wondering the metal parts are painted gloss black

I was a Logistician for 30 years and had worked very closely with Traffic Techs prepping cargo for A/C movement. Almost everything is either wood or plastic palletized, then placed on an A/C pallet, netted and strapped.

Edit.

The same goes for shipping by Seacan/ Conex. Palletized and strapped

I think since around '07 on it was that way. I think from then to '16 I only ordered one kind of tire not already mounted and that was a nightmare.

I was not. But I did take the the Air Force Load Planner’s Course. (and slept in a Holiday Express) Indeed, everything must be palletized in some fashion to protect the floor of the aircraft. Even a piece of gravel from a vehicle tire can pierce it. The 463Ls are easy to scratch:

Was wondering where those hot boxes ended up.

Where did you get the air force pallets at?

Wow, outstanding information from all, exactly what I was looking.

Thanks all

Just a quick scratch build.

if you ever market them let me know.

Done for protection in storage. Back a while, there was an article in, IIRC, Business Week on the refurbishment of Abrams tanks, and one of the pictures showed a rolled-up track that had been cleaned a couple of days prior, and the metal parts were already a bright orange from a light surface layer of rust; painting it black protects the metal until the tracks are mounted, and the paint wears off quickly in use,

Re Tank tracks:

I’m not sure about today, but when I was in, new tracks were NOT painted but coated with a sticky, gooey black compound (cosmoline or similar) to protect the metal parts.

This stuff wore off pretty quickly once in use.

Ken

Last time I ordered them it was still there

On a side note…Forklift mounted track roller ![]()

https://www.army.mil/article/23470/depot_invents_builds_track_roller_for_vehicle_repair

H.P.

I’ve seen that, but not on action at the time. ![]()