When I discovered that gap in the gooseneck I kept trying to figure out what I was doing wrong???

What type of glue are you using for your weld beads ? Have you considered using stretched spruce or styrene rod ? A plus is that it reinforces the joint as well.

I have had no luck with the stretched sprue method. Just cannot get the consistency of stringy rod I would hope for.

Honestly I never thought of using fine styrene rod (stupid me)

(Place Homer Simpson GIF smacking forehead here.)

My workroom supply yard of Evergreen shapes and rod is fairly extensive with plenty of fine rod!

I will look into that ! Thanks!

Yes, I suppose it’s is tricky to achieve consistency in long runs with stretched sprue .Evergreen even offers quarteround, in .030 & .040 diameter I think.

I got that in stock too!

Before this moment I always looked at that quarter round as just something to use in model structure construction.

Right now my mind is leaning towards using the very small rod.

I typically use .020 or .030 rod for welds in this scale. I’ve been building 1/ 25 trucks for a while, and they’re sorely lacking much detail

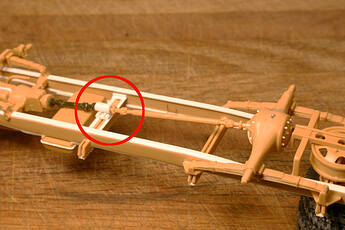

helicon ~ one of my bigger complaints (I admit I’m weird) is when a hobby manufacture will show just a single LONG driveshaft under a vehicle when clearly even these 1930’s & 40’s vehicles would have had a two section main driveshaft with a pillow bearing mounted somewhere along the length of it!

. Opel Blitz Frame . Mercedes FrameThese were my modeling efforts from long ago, to make the old Italeri Opel and Mercedes trucks much more accurate. (Never did find a proper rear differential though. The diff from the Italeri Mule or the Tamiya Kommandeurwagen would have worked perfectly but why sacrifice an entire second kit for just the differential???)

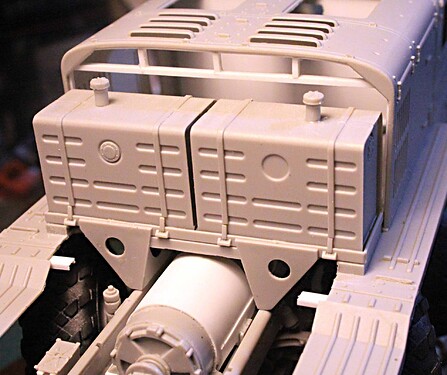

Making some progress here, working in and on the 7410 “attic”:

Still need to build that radiator overflow tank and I also want to come up with a bit of structure support for those two fan drive gearboxes on the front of the engine.

_____________________

Based on the location of these two hinged covers I am thinking there might just be two large auxiliary fuel tanks in/under that attic sheet metal???

If only I had a couple of spare fuel tanks off the old MA3-537 I think I would tuck them in there!

I really don’t want to scratch build those two fuel tanks but I just might have to.

Anyone have a “parts” 537 at home that they would want to sell off just the fuel tanks, filler pipes and the mounting/drainage tray underneath???

I do have two 537’s on my display shelves but their fuel tanks are definitely spoken for!

Having trouble getting motivated to work on those twin cabs. My favorite part of the build is now just about over!

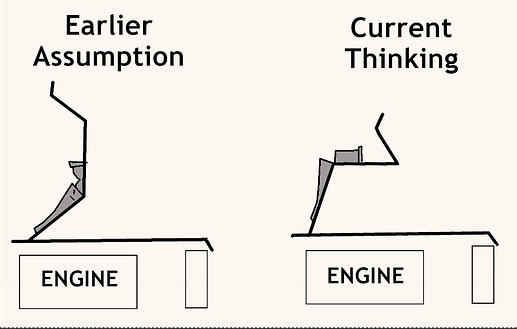

Any thoughts (or reference photos) on just how this LARGE front engine hood (bonnet) is supposed to fold???

The fact that the front third folds upward is a no brainer. This gives the operator quick access to the radiator, (cooler,) radiator hoses, the overflow reservoir and the fan drive systems.

Just how that second hinged section is intended to fold is more of a mystery because of those large ram air intake horns. At first I thought perhaps those forward horn sections were made of heavy rubber and would fold back into the rear portion and collapse as you raise that middle hood section.

But now I think I might have that backwards: ~ that intermediate section folds DOWN and it is the section at the rear that folds upwards.

I think I would have framed up and hinged the forward section directly to the body as a totally separate piece, to give the operator some place to stand while they worked on the engine

Why Michael, how do you know that is not exactly what has been done???

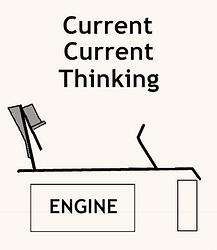

And now for my Current, Current Thinking:

(I apologize for it taking me SO long to get to what has to be a very obvious conclusion!)

I think there just MIGHT be an open engine bay in my future! And of course the twin cabs already tilt forward on the model for engine maintenance and viewing.

Anybody got a 7410 Tech Manual who could share a few photo-scans???

SIDEBAR:

All us model folks who have been loosing sleep over not being able to remove the mold lines down the center of the tires on the many assorted model offerings of big MAZ 8x8 trucks can now rest easy.

Photo by Yuri Pasholok via SVSM Gallery

There is a prototype for everything! (Only Joking)

Well maybe, but won’t that really only work on “0 hour” tires? I am guessing and will probably be wrong but at some point and probably shortly (a week or 20 miles of pavement driving) depending on use the seam disappears and back to the same issue? While similar to the German suspension seam but that one would stay “forever” this find is a temporary fix.

Not saying this is a bad thing, another tool in the tool box but I can see guys doing the Spanish school of weathering on the truck and having zero hours wheels on it.

Yes of course. All brand new real tires that I know of have that seam down the middle for the first few hundred miles but it quickly wears off.

I was only joking.

Personally I use a Dremel with a small abrasive wheel to try and wear those seams down. Sometimes that works and sometimes that rubber is just tougher than stone!

It wouldn’t really matter since the Spanish School is not realistic either, just very artistic. So inaccurate wheels would just add to the artistic expression.

OK, you guys have me on this one. What is the ?“Spanish School?”

The latest fad in weathering and finishing that includes heavy chipping and wear that was/is not present on real vehicles. It also includes color modulation, filters, pre-shading, panel line fading and all the other new buzz words. Since many model builders want the viewer to know how hard they’ve worked, the effects are frequently over-done, and don’t resemble anything seen in the real world.

Heavy ~ That has been my exact description for most of the “WINNING” tank models I come up against in recent years. I call them “painted ladies” and hoores. (whores - but with an Irish or Cockney accent.)).

I no longer compete in the “closed top - Armor” category as I WILL NOT build an Armored vehicle to look, in a manner it NEVER appeared in real life! I’ve been around enough AFV’s to know what they look like after even a day in the field - and had to clean them.

Sorry guys - not trying to offend anyone - to each his own, but I just won’t do it.

My thoughts exactly.

I am not trying to be critical of the work of others ~ again to each his own.

I am just trying to give a little public “push-back” to a modeling style that I don’t think is correct or realistic. (IMHO)

Opinions are like opinions ~ everybody has one!

(That’s how the saying goes isn’t it??? . . . or something like that! Ha.)