For a complete build will all the gory details you can check it out at FSM’s forum here:

http://cs.finescale.com/fsm/modeling_subjects/f/3/t/187851.aspx?page=1

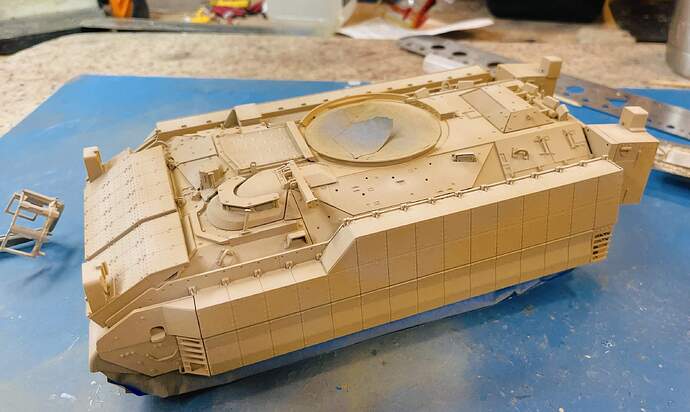

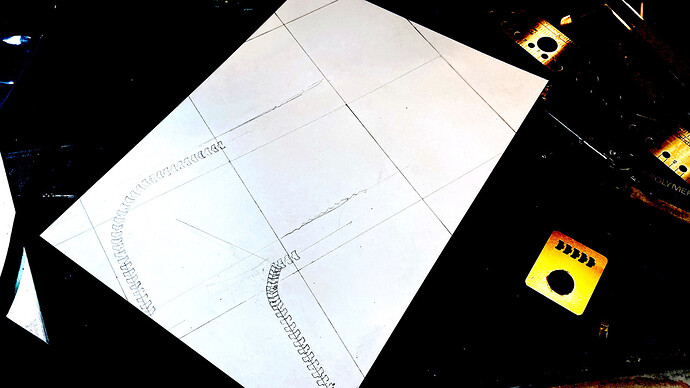

In this thread I’ll try and give some highlights and bring you up to date. I’m using one aftermarket set: Friulmodel Bradley Big-foot tracks. While I was excited with the Meng snap-together tracks as compared to the massively complex Ryefield Model Sherman tracks, I was disappointed that the tracks weren’t stable and came apart at the slightest side torque. I bought the Friulmodel tracks. They actually required less cleanup than the injection molded Meng track parts, and with a full pin going through the entire link, they are very strong. It did take some special handling to adjust the length after building them though. The Friulmodel kit came with a spool of 0.015" brass wire for the pin stock. It seemed a sloppy fit in the link tunnel, so I substituted it with 0.022" phos-bronze and drilled out the passages accordingly. Much better.

As a newbie, I’m limited to five pictures per post, so this post will be spread over several entries.

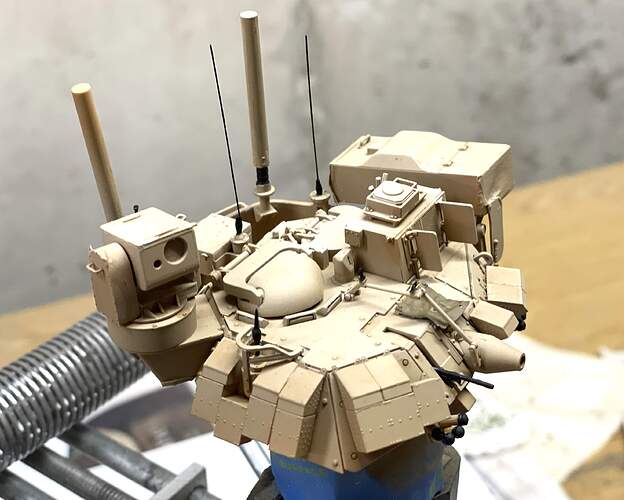

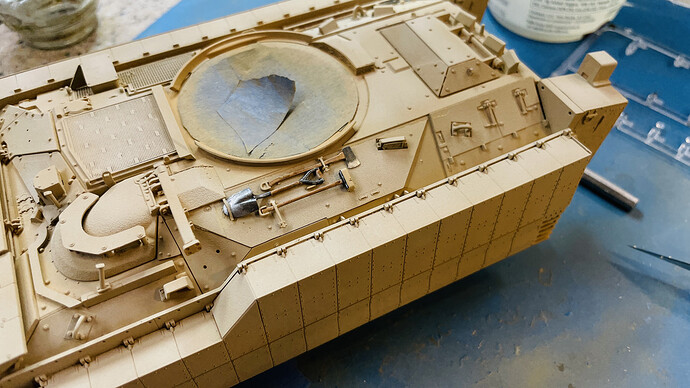

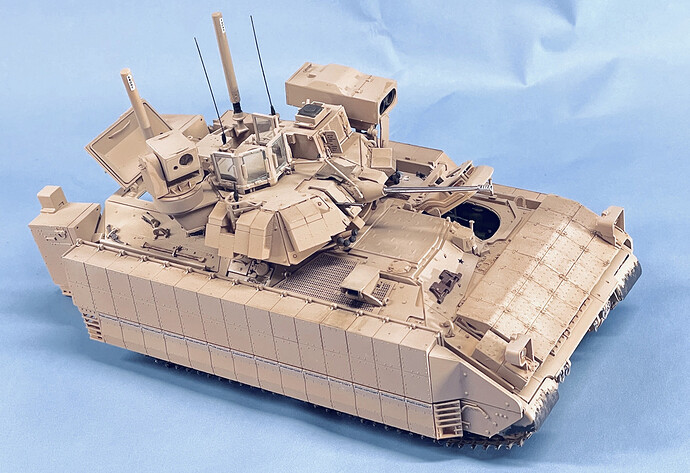

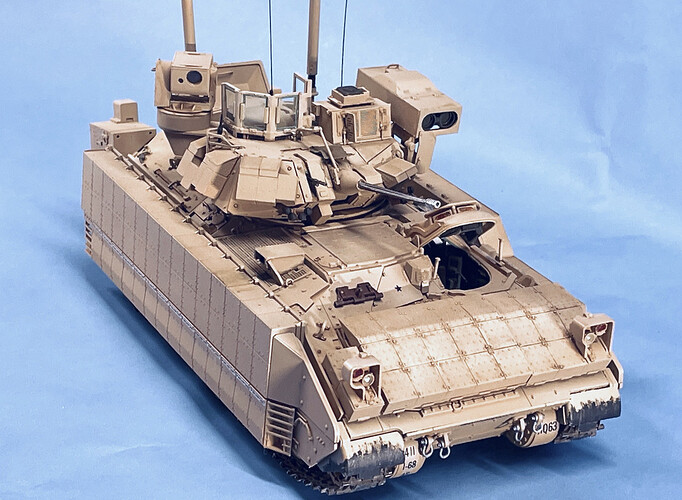

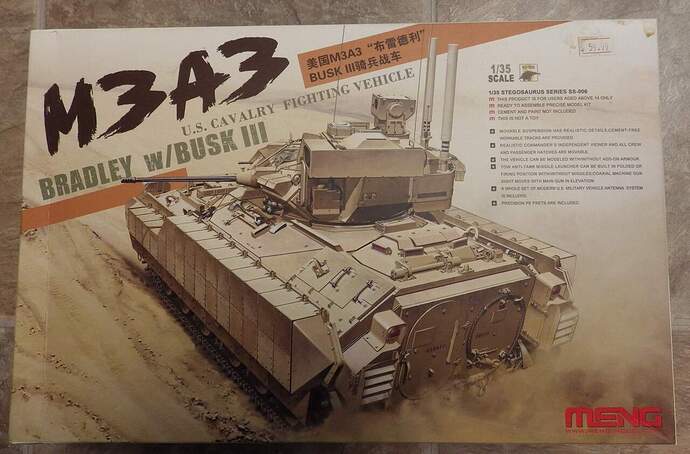

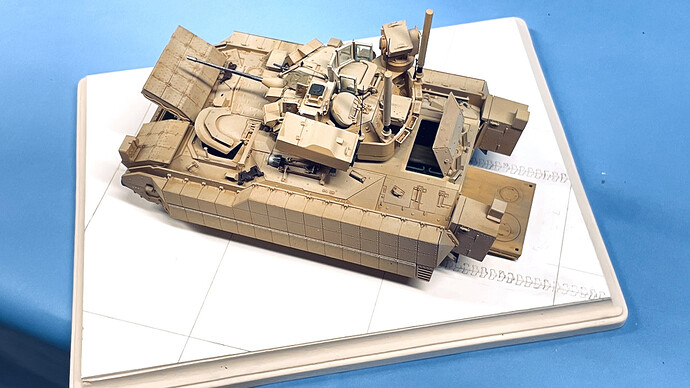

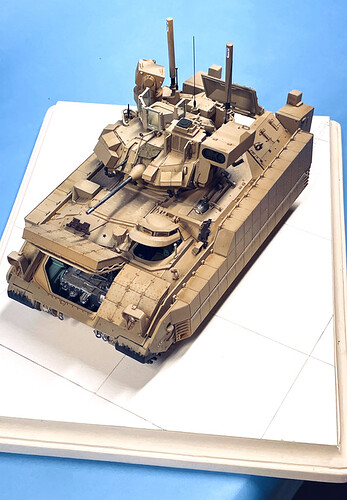

Meng, as you all know, is very similar to Tamiya in engineering and mold accuracy. It is a pleasant albeit complicated model to build. Total parts count is 874, but that includes about 170 links for the tracks. The road wheels, idler and drive sprockets are held with polycaps. Road wheels are articulated with styrene torsion bars that pass halfway across the floor pan. They work, but their suspension arms are quite flexible and really can’t do any real work. The suspension would really benefit from being die cast in metal, but that won’t happen.

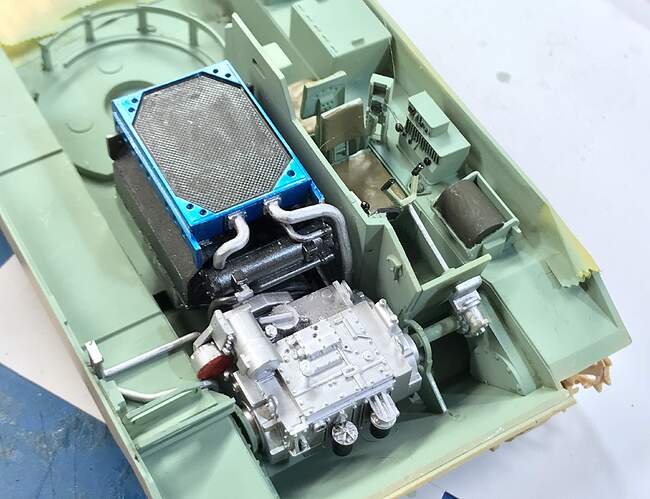

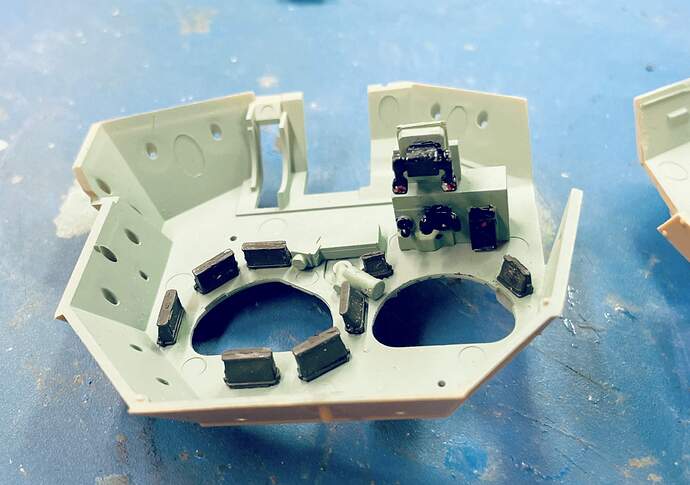

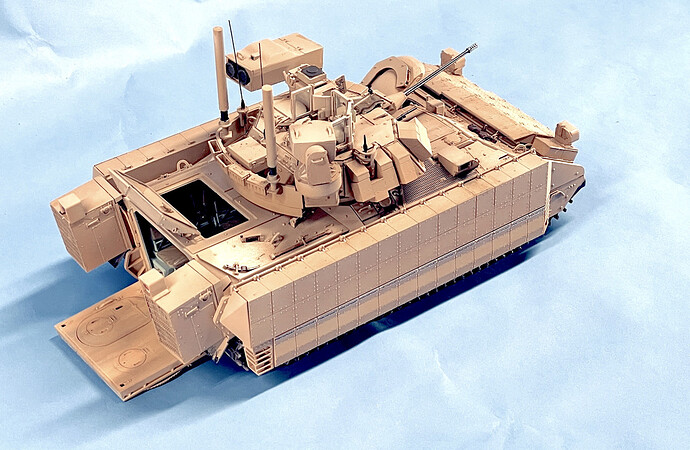

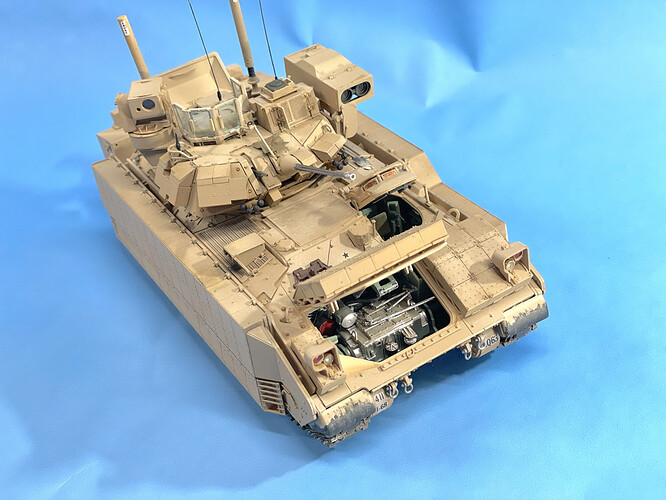

While the interior is fully detail, and I mean FULLY, you won’t see much of it when assembled. On my Ryefield Sherman I built a special display stand to hold the hull top above the bottom so you could see inside. I didn’t do it with this one. The Cummins 930VTA turbo diesel is a nice model in itself, but completely invisible in the model since it’s buried under the radiator and that’s covered by the hull top. All you see is the transmission and the trans-cooler heat exchanger at the engine’s front. You also don’t see any of the massive air cleaner box except for the forced air fan at it’s front. suspect the intercooler is in there for the turbo. I saying all this because I spent a lot of time doing perfect painting on engine and air cleaner never to be seen again. I even wasted time wrapping the exhaust manifolds to simulate the heat shields one the prototype, which also is not visible on the model.

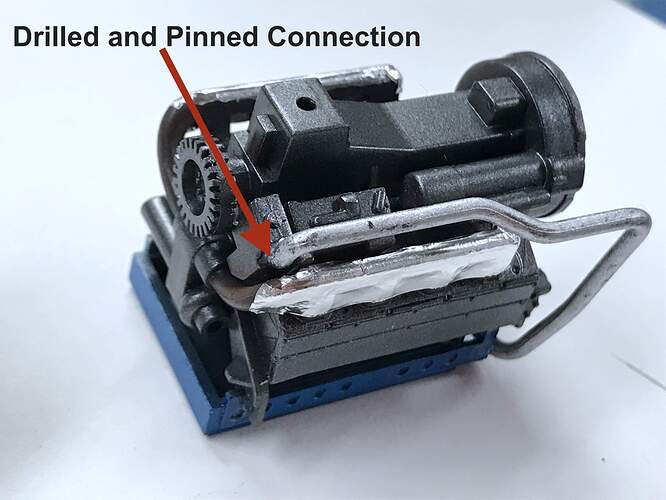

The engine is upside down in this image. The picture points out the reinforcement of the radiator tube’s connection to the engine block. The glue connection was very insubstantial and I used some phos-bronze wire to strengthen it. I’m never afraid to add metal connections in a plastic kit when it adds to security.

Here’s the air cleaner showing the non-seen paint job.

The instructions called out “Blue” as the radiator color. I chose it make it appear as anodized aluminum with a base silver coat followed by Tamiya Clear Blue. I had trouble finding photos of the real power pack that showed the true color of some of this stuff. The gun metal gray for the engine proper appears to be correct in looking a Cummins information.

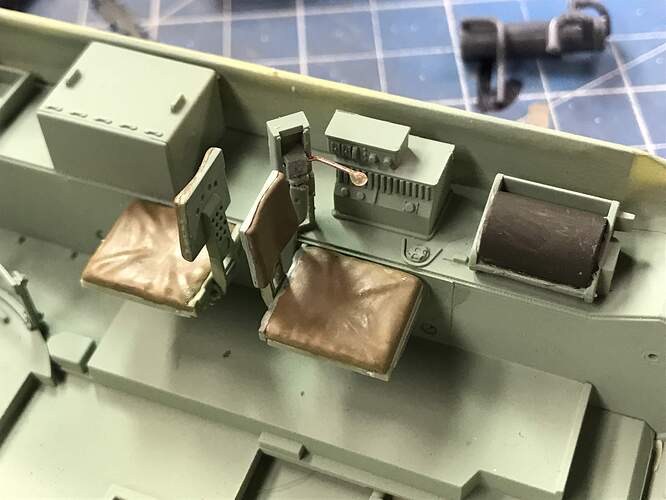

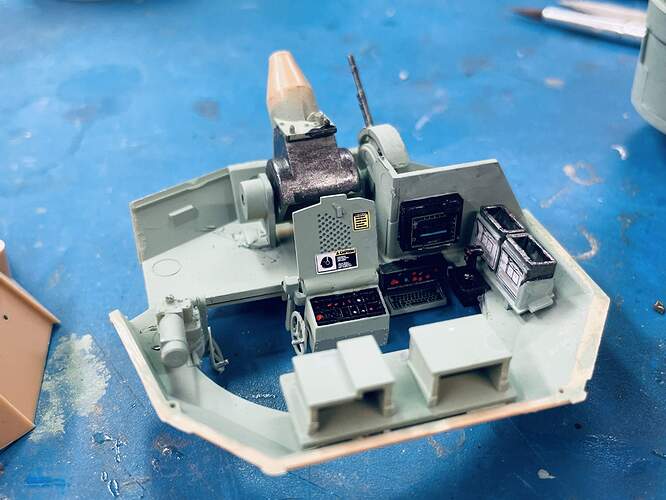

Good pictures of the driver’s compartment showed a missing seat-height adjustment lever so I made one out of 0.022" phos-bronze. I use Bondic UV-curing resin to create ball end on handles. I add the drop, hold the piece with the ball facing downward and rotate it so it forms a nice sphere and then hit it with the UV for about 5 seconds. I also use Bondic for clear lenses.

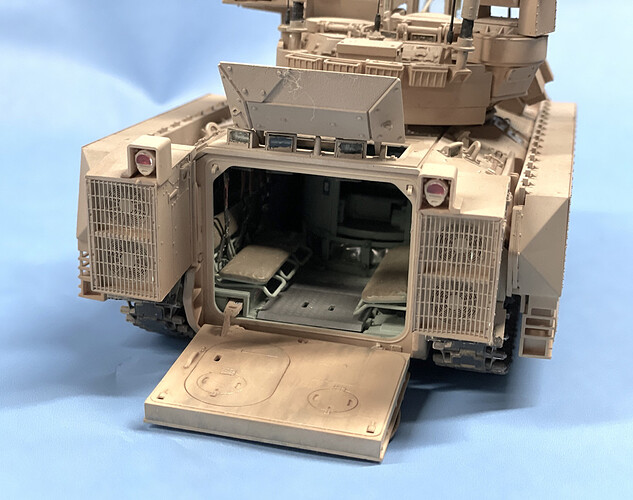

I mixed my own sea foam green using Tamiya Sky, a small quantity of blue and white. It came out pretty close. During college years and one year after, I spent my summers working at American Electronic Labs (AEL). it was the best summer job ever!

During my tenure, they had a contract to turn standard FMC M113 APCs into mobile ECM systems. This required stripping the tanks down to bare metal and rebuilding them completely adding an enormous amount of radio jamming equipment. I spent a lot of time in them and even got to drive them. This was during the early Viet Nam years, 1964 to 1968. Since they were new vehicles right off the assembly line… they even came with the 50 cal, M2 Browning strapped to the inside… they didn’t have preservative in them so needed driving once a month. AEL had a test track in the back lot and we drove them around on it. Like I said, “Really cool summer job!”

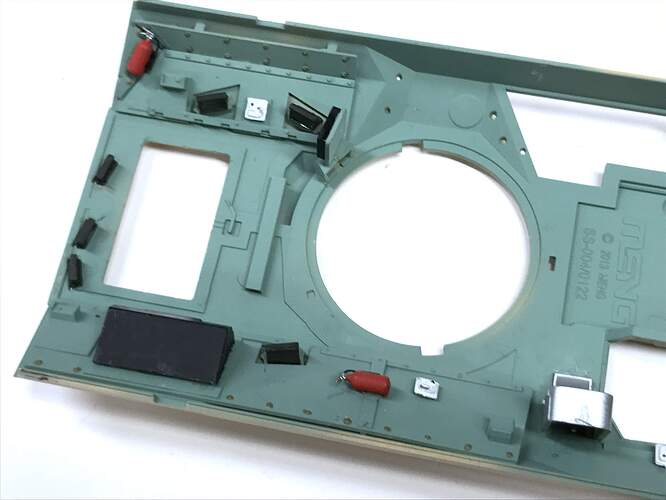

The tread plate on the floor is actually rubber on the rear Bradley so it doesn’t wear down to bare metal. It just gets a bit dirty. The lift link in the upper left is attached to the not-yet-installed lift gate. It kept falling out, so I taped it in place throughout the build until the door was installed.

That’s my five pics. On to another episode.