OK, new product of the combin-o’-bottles!

Available here: https://hobbymarket.gr/en/upgrade-conversion/1538-135-bottles.html. It’s a set of 60 bottles: 20 soda bottles (middle), 20 water bottles (right), and 20 classic coke bottles (left).

If you guys want this set, just know that this will be available. I still have the clear resin in the other printer and I know it works and works very well. I’m printing it right now. I might have also gotten my other printer working again, I’m not sure. The MICH helmets I had been using as a test printed mostly well in my last print so hopefully I gotten it working again but I’m still knocking on wood.

4 Likes

Nice way to litter the interior of any vehicle with water, soda and Gatorade bottles. or load up the Coolers that RFM supplies on some of their modern kits (Parts Tree “O”)

4 Likes

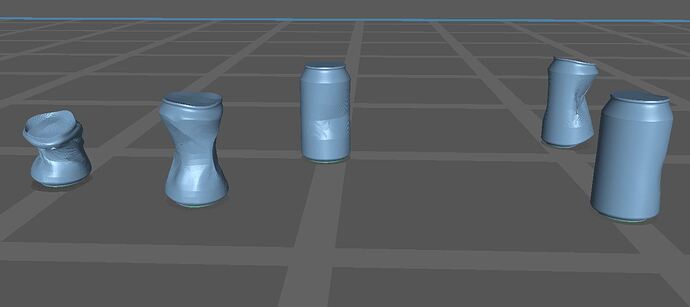

Unfortunately you gave me an idea… And those are dangerous with me. So I decided to crush some cans.

7 Likes

Crushed cans will add realism to a typical street in the Iraqi suburbs.

3 Likes

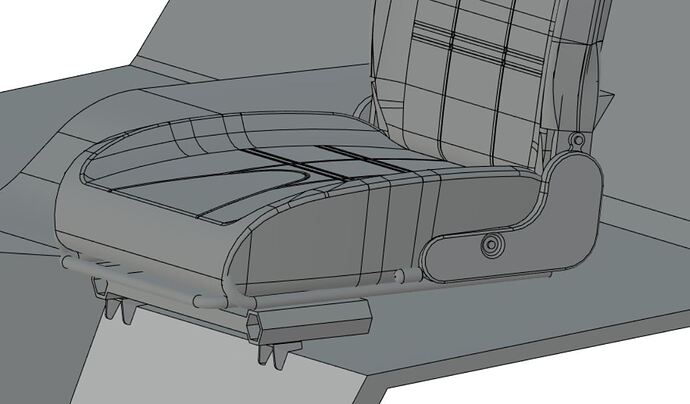

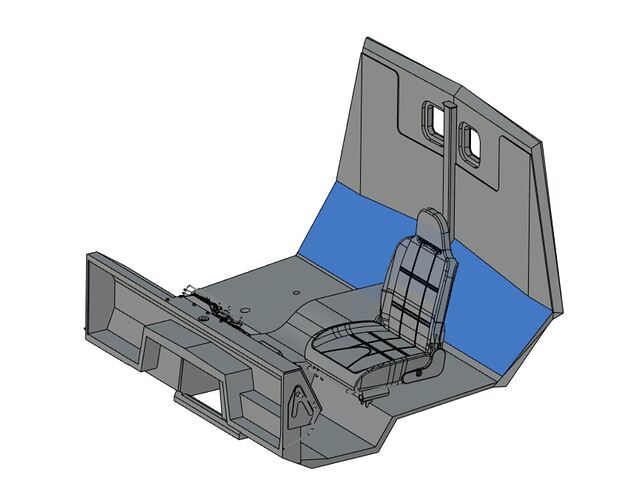

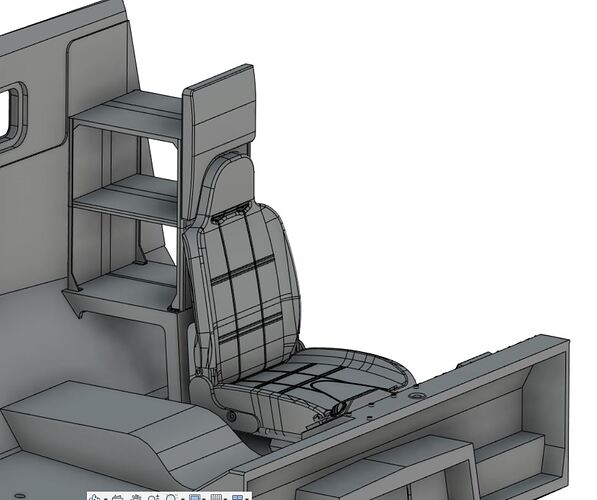

The LTAS seats are done. Haven’t started on the under-seat detail yet though. This one seat alone took up 29 sketches and 134 operations.

4 Likes

The seat looks very nice. Can’t wait to see cmplet cab.

And the work done on the lower half of the seats in the cab.

6 Likes

Very nice. Can’t wait to get these. It looks awesome.

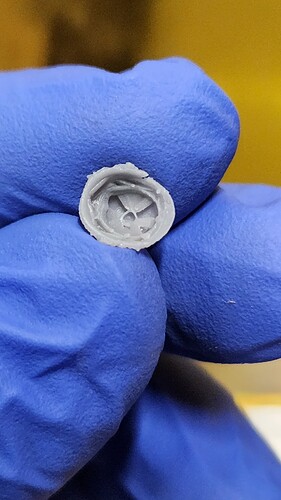

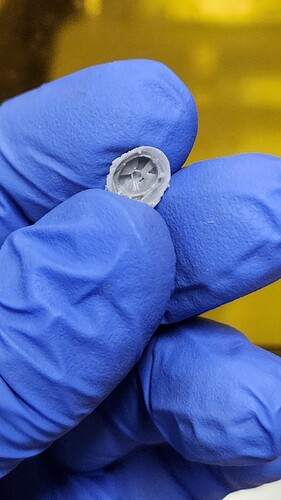

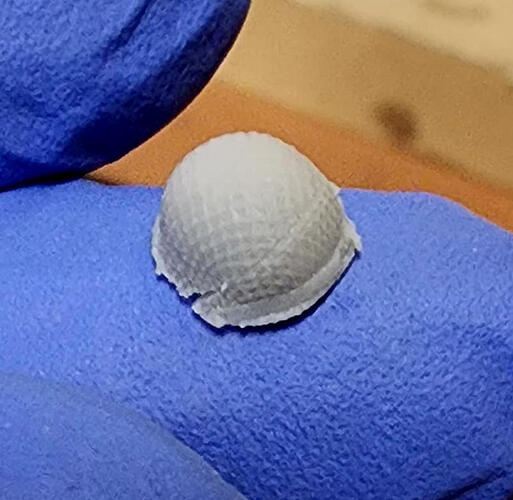

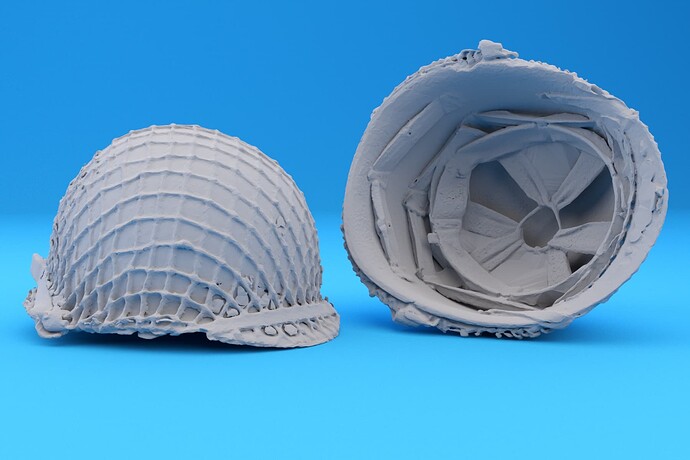

Don’t mind the photo quality, it’s late and a bit dark in the basement where I have to do my work. But this is why one uses 3D printing. An M1 helmet with netting and printed webbing. The webbing is 3d. It’s not just a simple blob protruding from the inside of the helmet. But don’t mind the defects you see here. It was printed on the “bad” printer as I was hoping I had it working. I’ll get a good version printed with the new printer… After I fix the hole in the vat film that CAME WITH THE PRINTER… Just my luck, huh.

I forgot, I do need to thank @165thspc Mike Koeing for sending me the helmet to scan. Took a while but I finally got some good scans out of it.

6 Likes

That’s impressive Mikey!

If you wanted too, could you change scale and print the same helment in 1/48 or 1/25 etc?

2 Likes

Needless to say; injection molding can never reach this level of undercut detail.

Looking forward to seeing your finished print of the helmet.

FYI - Just ordered your overload springs x 2 and the new firefighting accessories set from Shapeways.

I am corresponding with “graflex.com” to try and get them to date the flash unit I have as either wartime or post-war but for some reason they keep answering questions I didn’t ask, (perhaps they have me confused with someone else.) I have ask yet again and am still awaiting a reply.

I suspect mine is post-war but the designs did not change all that much except as to how the flash attached to the camera. The main tube still had to be of a size to hold 3 D cell batteries - that fact was universal to all the Graflex flash units.

Please add that Graflex camera case to your to-do list along with the film holders and the flash. These would all make for a very nice combined set to sell on SWs. (The 3 styles of camera, the flash, assorted film holder stacks and the carry case. Also consider doing the portable typewriter and it’s carry case as well.)

Just a little close up here.

2 Likes

They can be scaled but I’m not sure it can be scaled down. They’re pretty thin as it is and I’m afraid that any smaller and they’d be prone to cracking.

1 Like

And strangely enough this just now came up on my Facebook feed from Andrew Mooney:

And the new printer is down for a few days. The hole can’t be fixed. On the new FEP. Now I need to wait a few days until the new FEP cartridges come in. I’m really beginning to accept that it’s the screen in my big printer that’s failing. It’s just very annoying and time consuming to replace but come tomorrow that’s exactly what I’ll be doing.

I think I got my printer back up and running. I just need the FEP to be tuned correctly and I’ll be ready to go on!

I’ve been using slightly different print settings so I was able to lower the price of the MICH helmets by about $0.35. The M1 helmets are now available for sale. I’ve built up a small stock of them, a few dozen, so the first few orders will be shipped out quickly.

5 Likes

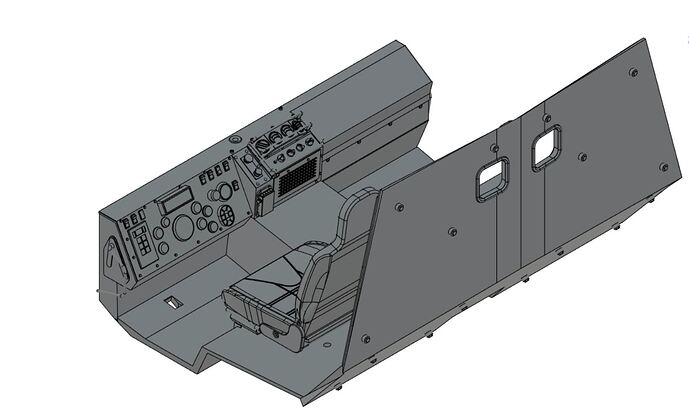

More work on the LTAS cab. For the past few days it’s been the radio rack. Still needs more tweaks because it doesn’t quite match up to the real thing with the ceiling attachment points. I’m also back in the printing game! I got the printer and vat figured out and everything’s been going pretty well so far, knock on wood.

5 Likes

A little bit of detailing added the AK-74M based on this picture that Frenchy posted. It still needs some detailing for the locking lever and other details but I can’t find any pictures of this particular side rail anywhere. Some come close but they aren’t this one so I need to kind of mash things together.

Haven’t gotten to the ribs on the handguards yet but that’s coming up.

2 Likes

@ MikeyBugs. I have a printing suggestion: Workable hydraulic cylinders in different sizes with brackets at each end. Is that a possibility?

—mike

I think that’s best done in metal. I can’t achieve a fine enough wall thickness that would also survive processing and I can’t achieve circularity (wow, my GD&T quality control class has actually come in handy!) between prints that would guarantee that the two cylinder halves would slide without interference. Solid cylinders, that I can do, but I can’t do workable unfortunately.

1 Like