My focus over the last few weeks has been completing the major sub assemblies for the interior. The Dash, door cards, Driver’s seat, what I’m assuming is a large air intake, the roll cage, the steering wheel were all built, as well as the interior pan, then they were primed in my basic mixture of Tamiya Gray/White lacquer primer.

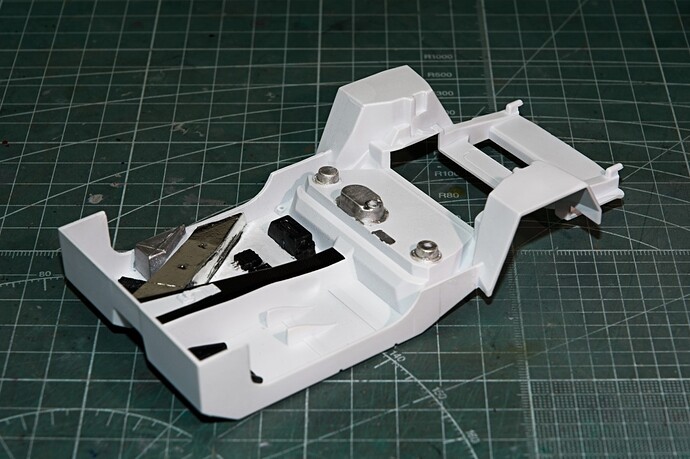

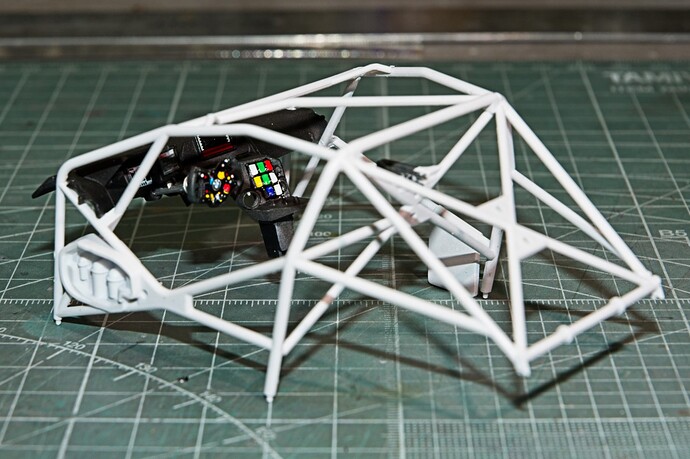

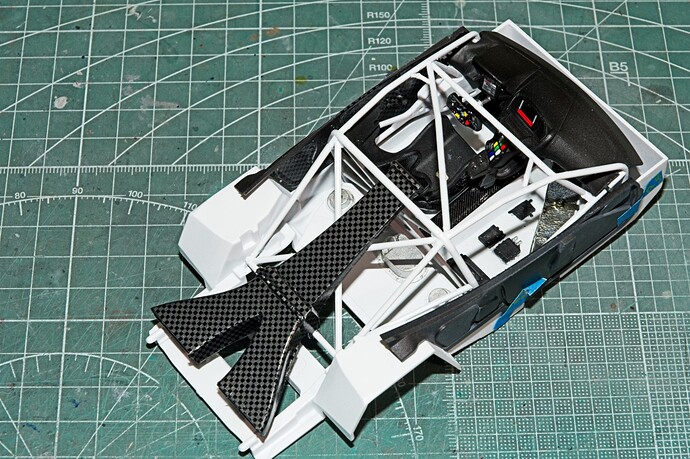

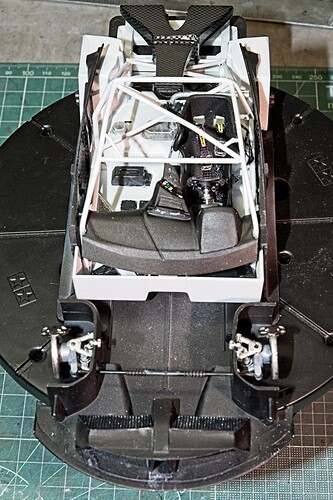

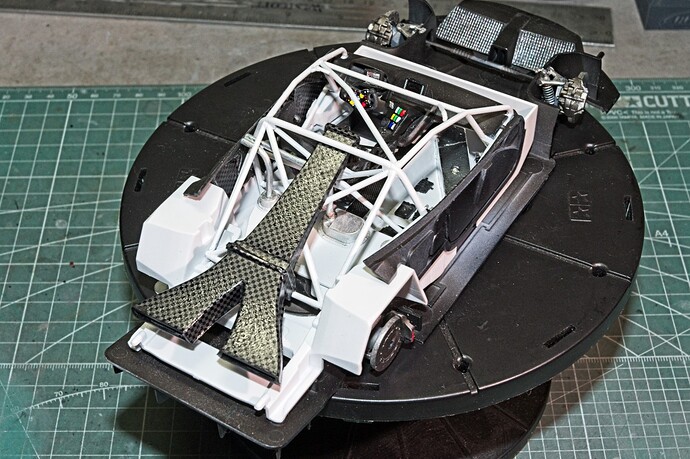

The roll cage and the chassis pan were painted in Tamiya X-2 Gloss White. I then hand painted the various molded electrical boxes Tamiya FX-1 Flat Black, and the two intakes for the gas tank, and cover for what I think is the fuel pump area Acrylic Flat Aluminum. The center consul top is a Carbon fiber decal. The structural raised area in the front right had a Aluminum sticker supplied with the kit, but try as I might I couldn’t get it to lay down flat, so I replaced it with Chrome Bare Metal Foil. The dash steering wheel assemblies were air brushed with Mr. Color Semi gloss Black, then the 4 computer screens had their decal faces applied.

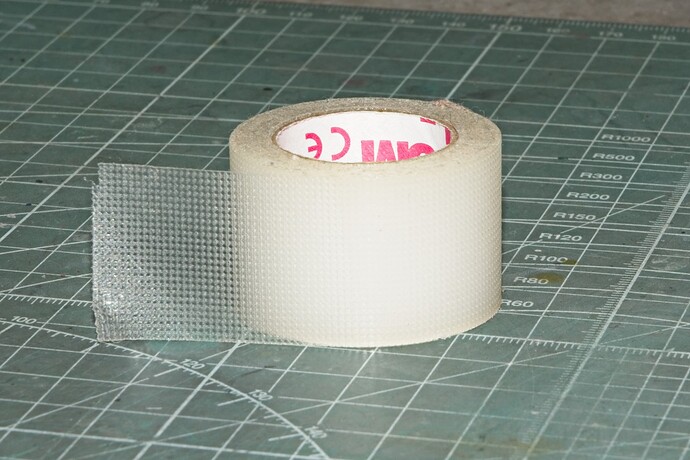

The Door cards were also painted with Mr. Color semi Gloss Black, and then the large Carbon fiber decals were applied which was no easy task as the door cards had several recesses and raised areas that asked more of those decals then I thought they could conform to. But the Microscale system, especially the Sol really helped, and then the Solvaset worked it’s magic. The end results are more then acceptable.

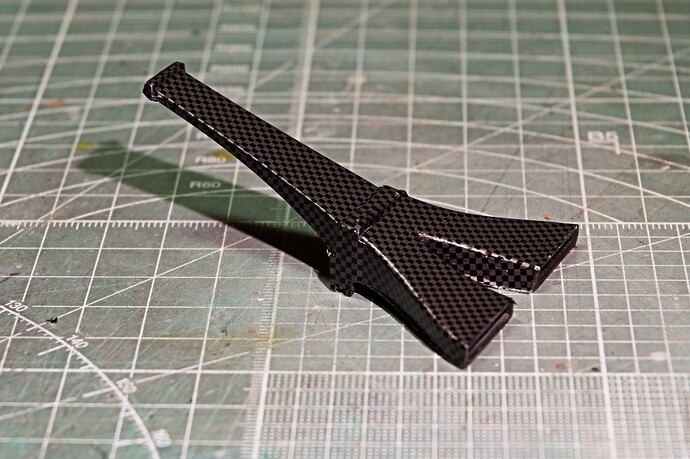

Next up was that large air intake. All four sides received plus the V were separately decaled.

The dash assembly was dry fitted in the roll cage and the fit was perfect.

Finally I addressed the seat. It to was air brushed with Mr. Color Semi Gloss Black to represent the driver’s shell. The outside of the seat is Carbon Fiber. The detail up set has one decal that has to wrap around from one side, the back, and then the other side. Well, I couldn’t for the life of me get it to remotely lay down. So put it back on it’s backing paper and let it dry for a few hours. I then cut it in half, and then cut each piece in half once again. The 4 pieces each laid down just fine, but I now have 3 seams when I shouldn’t have any. Still, it looks way better then my 1st attempt.

Finally, I dry fitted all the assemblies.

Next up is tackling the 6 way racing harness and all that PE, the tires/wheels, and then it’s back to more detail work and decaling on the body shell.

joel