Solid! ![]()

Love it when a Styrene plan comes together! ![]()

—mike ![]()

nice, very nice

Scratch-built storage/stowage boxes are the coolest to build. I think they “add” to just about any armour build

Very nice ![]()

The nail detail looks really good! ![]()

—mike

While jibber-jabbering with a buddy last night, the subject of hydraulics came up. Yep, gotta’ have a hydraulic cylinder. While I was at it… upper decking and end caps. ![]()

Good thing, because Inspector No. 172 payed a surprise visit to the BombeWerks today. He may be small but still tends to be kinda’ picky.

He spewed something about… “What is this terrible finish on the Z-1? Did you run out of sandpaper or something? And what has been decided about the paint? … Schnell! Schnell!”

Well Kinder, I think that’s gonna’ wrap things up for this scratch-build segment of the ‘Z-1 Riesige Sprengbombe’ plus the ‘1.5cm Bombenschlepper-lifter.’ … Yeah, I’ll probably think of something else tonight. ![]()

Stay tuned for more stuff coming your way filmed in… ‘One-Seventy-Two-O-Vision!’ ![]()

Thank’s again for having a look!

—mike

![]() If you cut Herr Inspektor’s base off he might just go through the hatch & you could slam it shut

If you cut Herr Inspektor’s base off he might just go through the hatch & you could slam it shut ![]()

![]()

![]()

![]()

![]()

![]()

The addition of the hydraulics looks great. Good idea

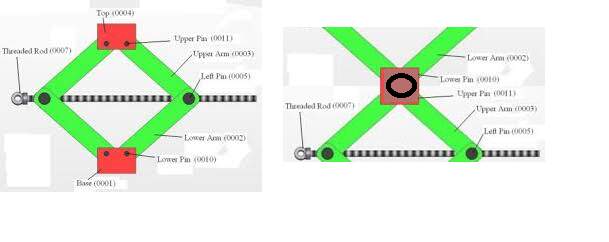

The idea of the scissor lift is that when the bottom sections close together, the upper sections also close and raise the platform, which means the ends of the scissors need to be able to get close together… in other words, both ends need to be able to move independent of the upper rectangle bomb support rack and the lower platform. As they close together, at the top, the platform runs the risk of becoming a seesaw (teeter totter?) depending on the weight distribution in the rocket/bomb - without support on the closing scissor, it might fall over. The hydraulic on the one end would tend to force that side up and the upper support over on the other side, not up, unless the opposite side was a fixed pivot.

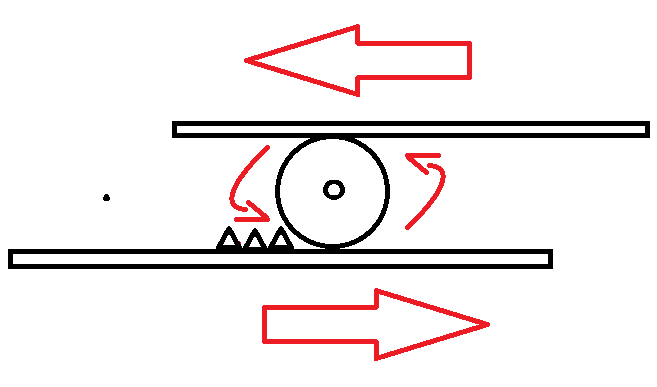

You need an actuator screw to pull the ends together. This simple jack stand shows the idea. The actuator is on the top here, as it would not be able to be turned on the bottom as the handle would strike the ground.

Basically the same principle of the manual car jack :

To avoid the lift scissors going sideways as per the jack with the fixed pivot end, you could have a centrally located motor, with separate actuator screws leading from that and attached to each end, with each end on rollers. That way the actuators pull each end together so the lift rises centrally, not up and outward… and as the central mechanism is bolted down, there is no risk of the scissors running to one end… and the limitation on height would prevent it going too high and teetering. A Hydraulic each end would be more like a shock absorber, only there to be a safe guard against it tipping.

Dr PetBat D. Sc BSA ( more BSA than anything ![]() )

)

…and by actuator screw. it could be a simple bar with teeth along one edge, like a sawblade. There could be a central gear with teeth that mesh onto a bar on the top and one on the bottom. As the gear turns, it draws the top bar in one direction and the bottom bar in another.

There’s a Petbat loose in the laboratory! ![]() Somebody get the Diorama Polizei! … and tell them to bring the big shears!

Somebody get the Diorama Polizei! … and tell them to bring the big shears! ![]()

![]()

![]()

![]()

—mike ![]()

"Once the rockets are up, who cares where they come down?

That’s not my department, " says Wernher von Braun.

![]()

That chest is mighty impressive, Witney!

again. ![]()

This really does not qualify much as scratch building nor a conversion but rather simply as adding more detail to a model: