Good detail tip. Thanks!

Aye, yah, mahn… me dem like de workable hydraul, mahn! ![]()

![]()

![]() Lee “Scratch Builder” Perry in da mix

Lee “Scratch Builder” Perry in da mix

Hydraulic Cylinders made from Evergreen or brass tube be much easier to build, No???

Drilling out plastic sprue. Wow man my hats off to your success on this!

Indeed Sir brass would’ve been so much nicer. I need to get (or build) a legit soldering station so I can work with brass comprehensibly. My first attempt was with brass but with total Fail results.

@kosprueone

Take a look at resistance soldering before jumping in

and if you want to build your own:

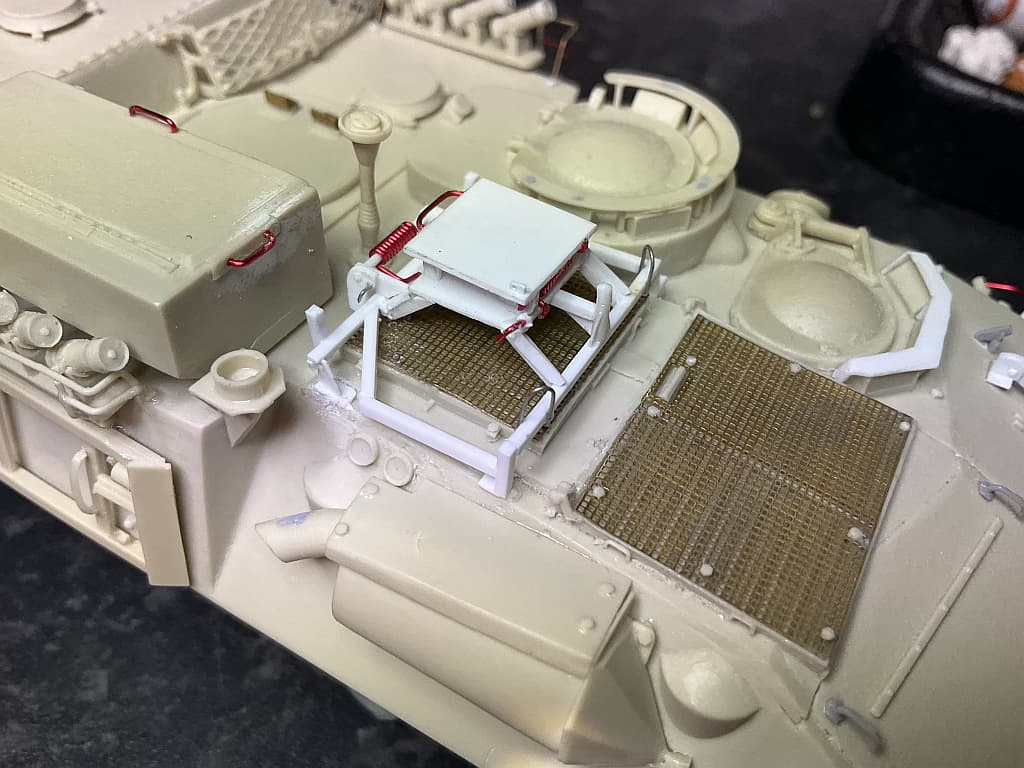

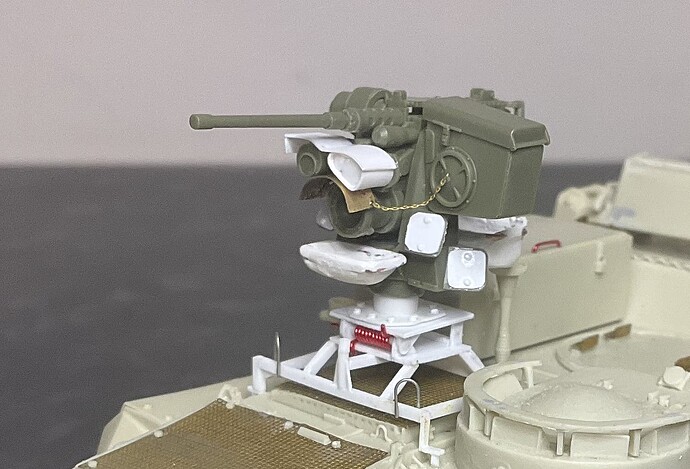

Not a fancy as some of what you guys are doing/have done, but my scratch built Seal Systems Spider mount for the ASLAV I am working on:

You may decide to get a soldering station as well since the

resistance soldering isn’t the one and only best tool for ALL jobs.

I used to be a member of a model railroad club where some members

built their own rolling stock from etched brass.

Lots of soldering points and the eternal issue with already soldered joints

becoming unstuck when soldering small parts onto a locomotive frame.

Resistance soldering worked miracles in those situations.

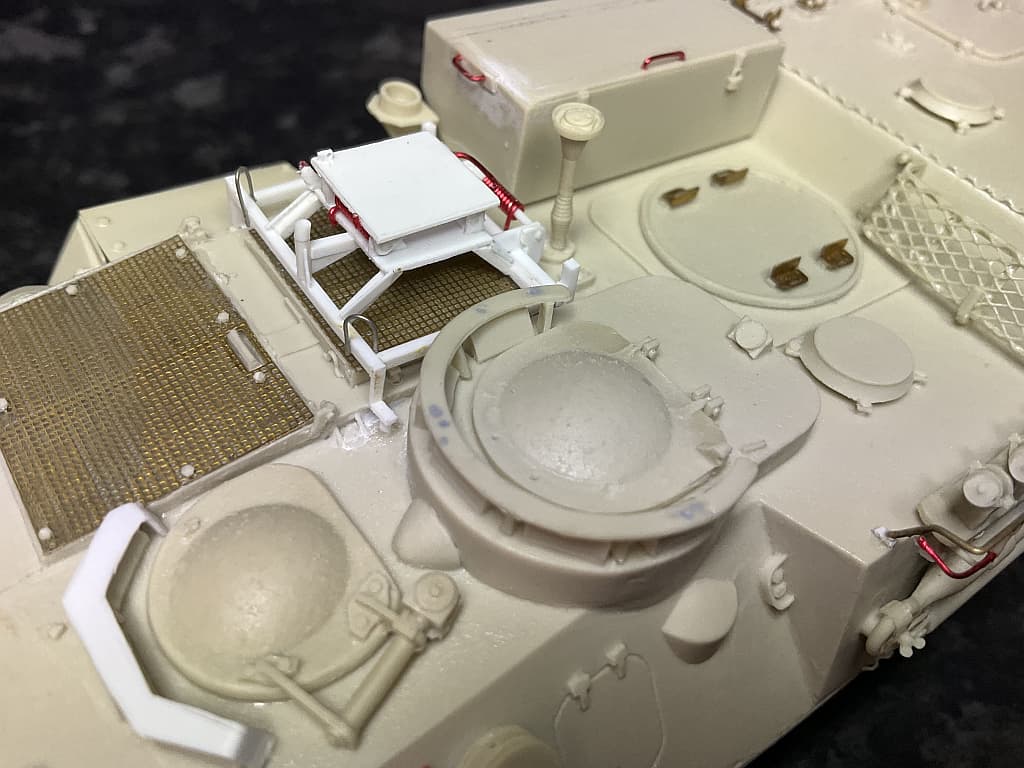

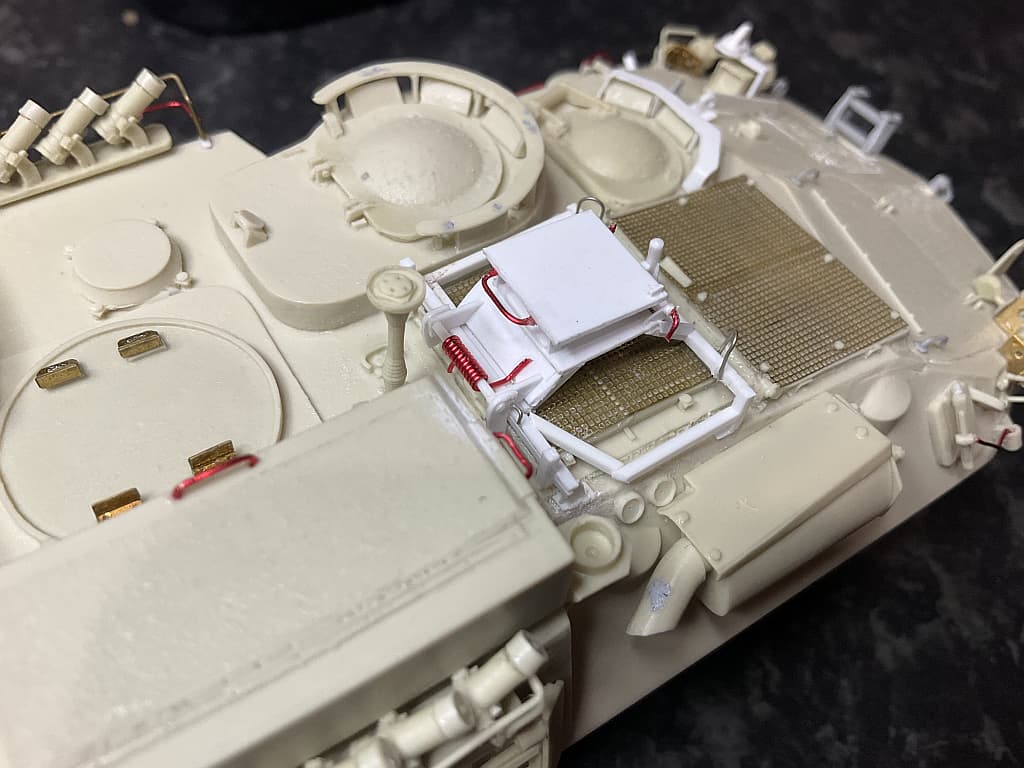

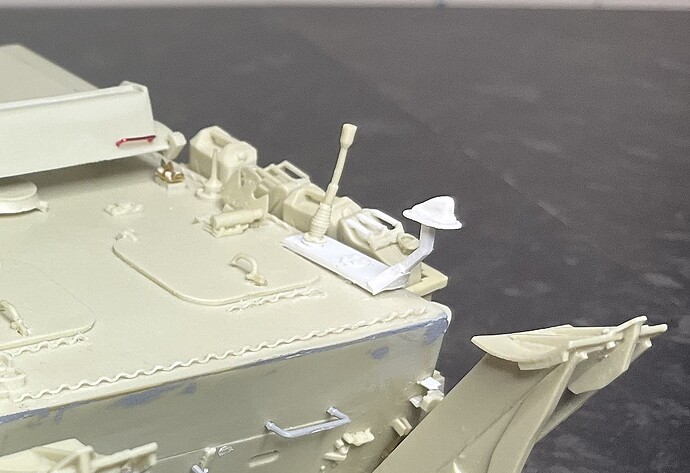

Some other bibs and bobs on it:

Since the above pic was taken, I was sent a photo of the mount minus the gun and realised the bolt plate for the gun was larger and retained the ‘point’ of the rectangle at one end, so that got changed.

Just put decals on last night:

You Aussies and your dang spiders! ![]()

![]()

Looks pretty dang fancy from up here! ![]()

—mike

Wow, very informative. I especially like the home made rig

More M55 details:

In this view of the vehicle’s right side, you can see the operable copper wire door lock, the hold-open hook of the commander’s hatch, and that the projo lift’s track consists of two parts that join sort of telescope-like. Here, you can also see the single detail that took me more time to think up than anything else: The right hand side spade lock (that looks like a trailer coupling).

In two of the earlier pictures, it can be seen open; this one shows it closed, and here’s how I constructed it:

The incorrect closer part shows the lock’s “hinge pin” of strip plastic, the other one is what went on the model:

Pushing the “hook” into the housing moves the slot over the plastic strip, thus arresting the hook. Pulling it out allows it to rotate around the strip in the round hole. Not completely prototype-like, but it works:

I think the spider mount is excellent!

So here is the box next to what it started out as:

Then the finished box, prior to painting:

The whole thing was constructed from sheet bass, cigar box wood, K & S brass, wine bottle foil, (the thick stuff), meng bolts/rivets and various bits from Evergreen or Plastruct. I THINK I am going to mount this on my 1/25th scale Sdkfz 263, well when it gets the build gets going.

I love it when cigar box wood comes out to play. Very nice work! ![]()

![]()

—mike

Justsendit,

Thats my reason for smoking cigars, “wink wink wnik”, that’s what I tell the doctor at least ![]()

Thank you for the kind post

great attention to details. Really nice work

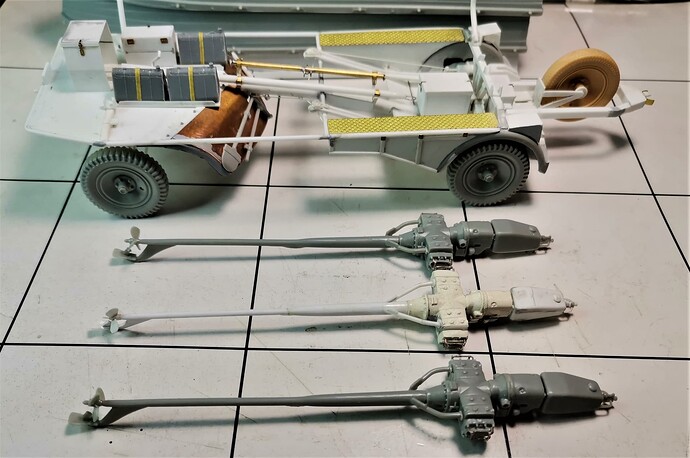

Got the third Sturmbootmotor scratch built (styrene+Miliput molded in Blue Stuff Mold)- a big Thank you goes to Mike Koenig @165thspc for his nudging!

The Sd.Anh.108 now has a full complement of Sturmbootmotors:

Cheers,

Angel