Hello everybody,

today it goes round, borrowing from an Oldie of The Spencer Davis Group - Keep On “Bending”, so everything has been said.

The thick 24’’ ring line is on the program, and therefore quick to the work.  The hot air gun is already ready for battle.

The hot air gun is already ready for battle.

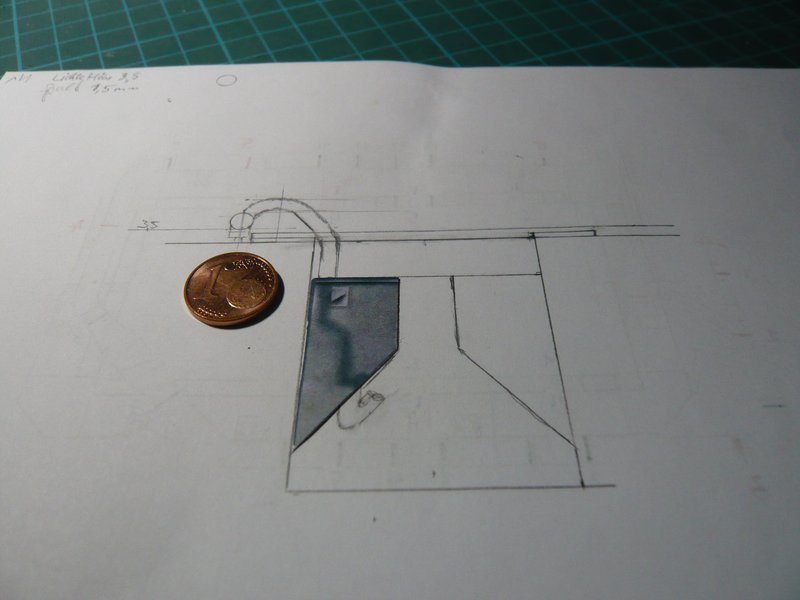

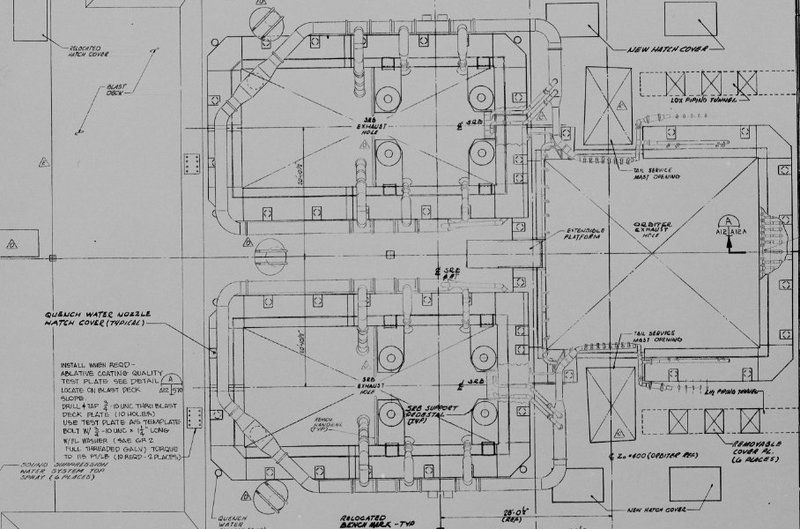

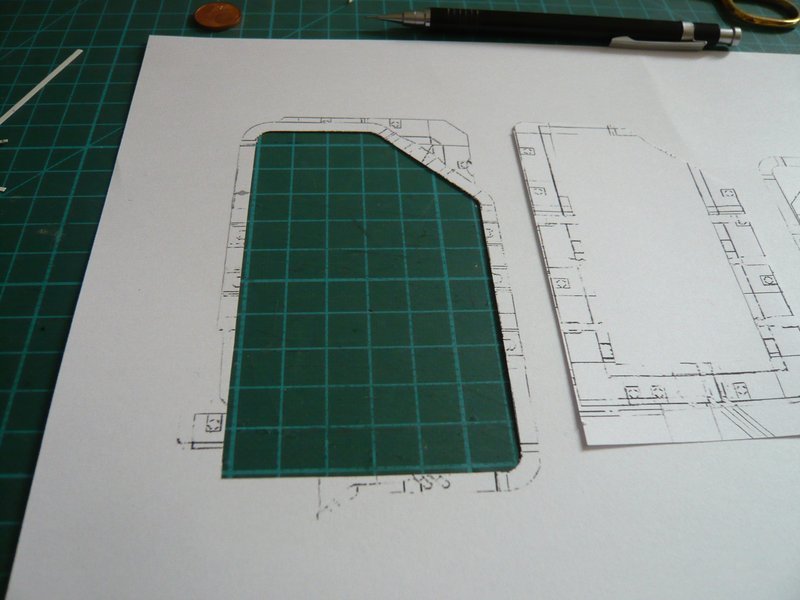

Before starting I still had cut a recess in the template, because the sleeve for the thickening of the pipe must be threaded before bending, otherwise one has a problem, because afterwards it’s impossible.

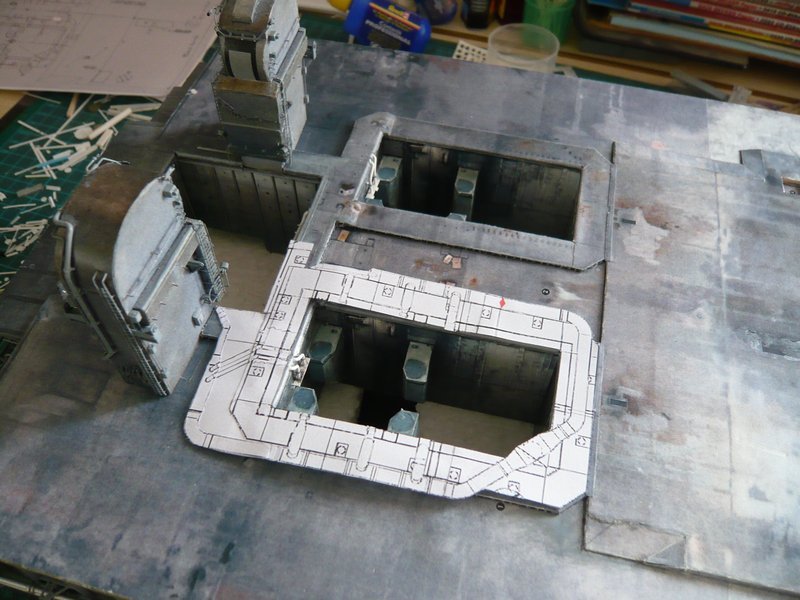

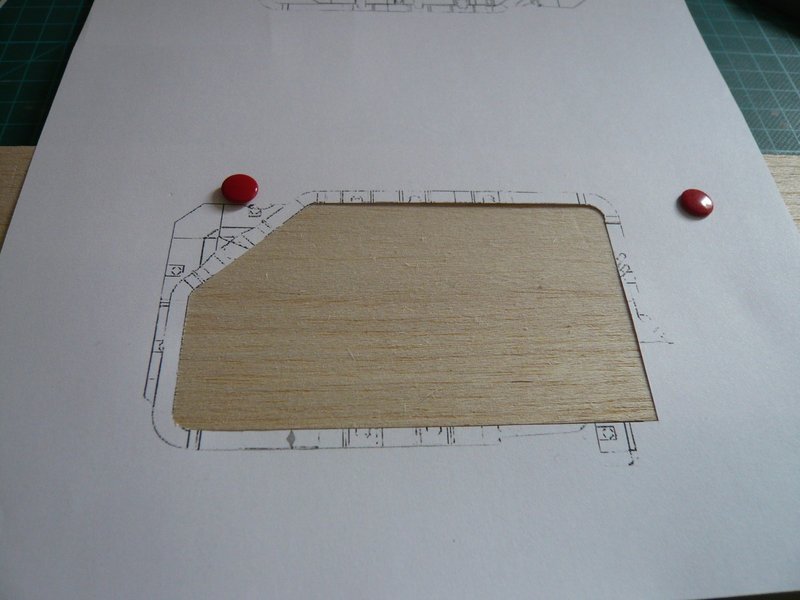

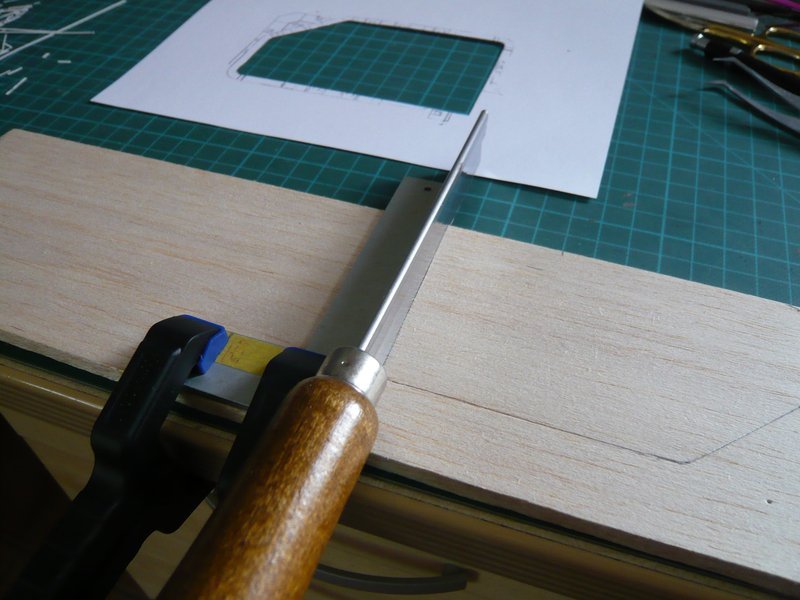

It’s important for the bending of the pipe around the Balsa template, that one gives the rod no chance to dodge, it must “obey blindly.” For this one must squeeze it into a stable Balsa corset til immediately prior to the bending point.

Then, the bending area is moderately blown with hot air while the rod is simultaneously bent gently until the plastic starts to soften what happens relatively abruptly.  Therefore one should then align the rod preferably immediately and over the entire length at the next edge and fix it in this position until to cooling down.

Therefore one should then align the rod preferably immediately and over the entire length at the next edge and fix it in this position until to cooling down.

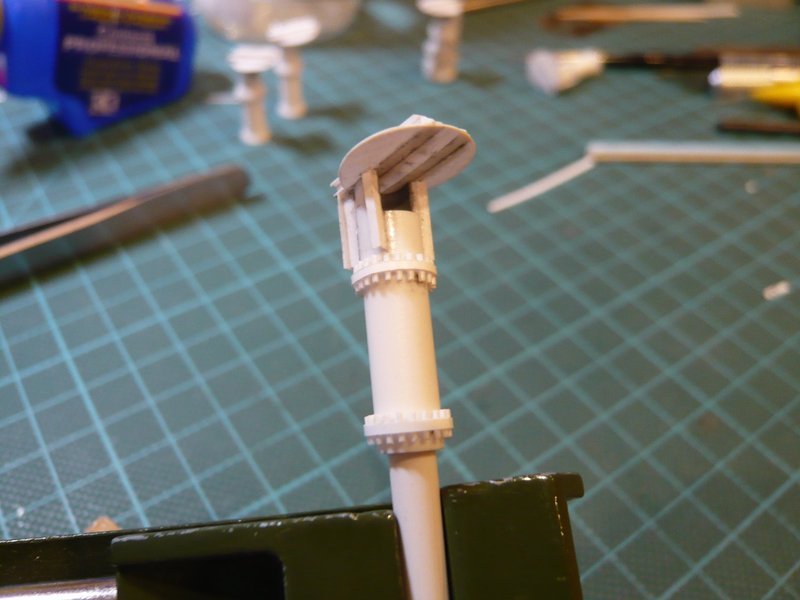

And here the handy rod (Ø 4 mm) has got already its first 90° bend.

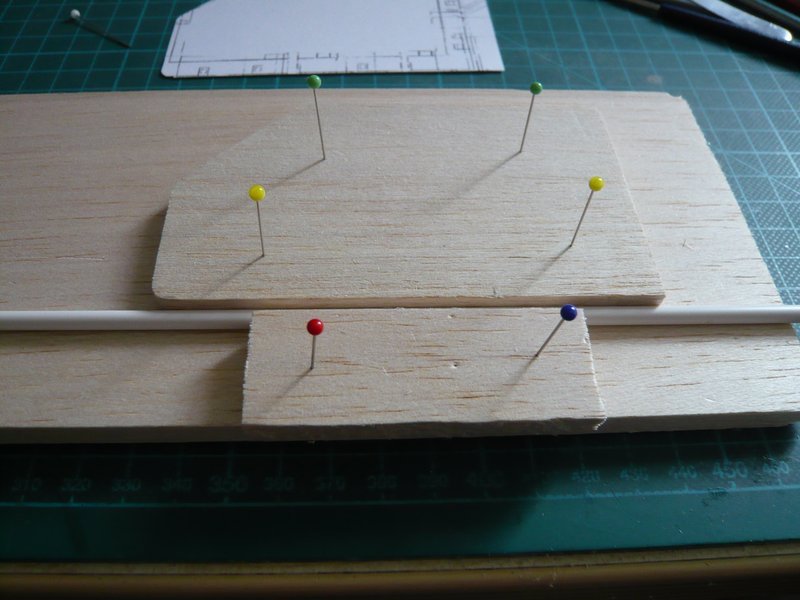

And if everything has worked well, this bending is virtually “frozen” and also after removal of the corset dimensionally stable.

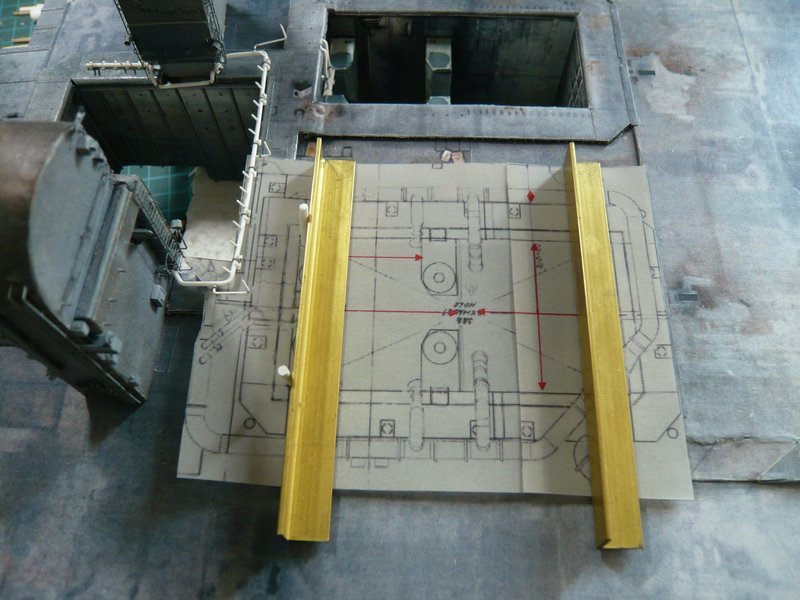

In order for the ring line remains planar during the following bends, because of the sleeve one must not forget previously to underlay corresponding compensating strips.

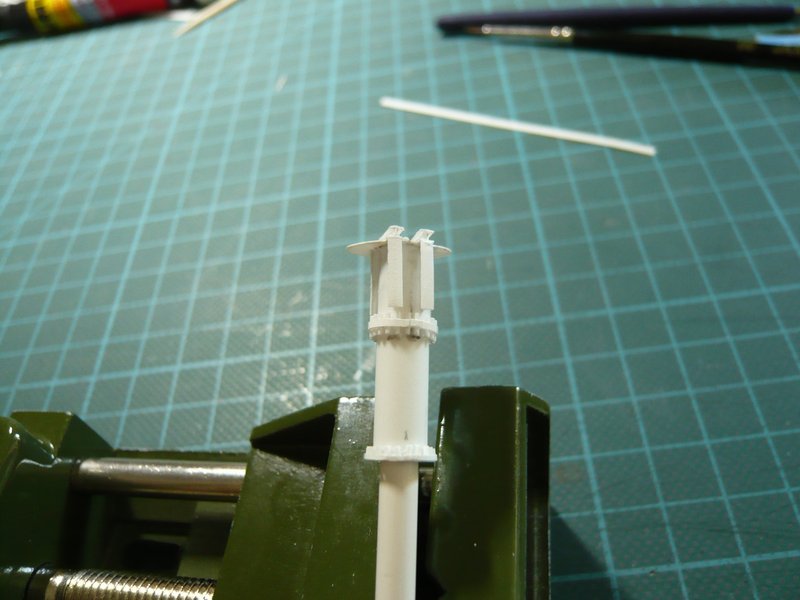

And then already follows the 45° bending along the slant with the sleeve in the recess.

Then the area for the next bending point is fixed again,

after which the second 45° bending follows.

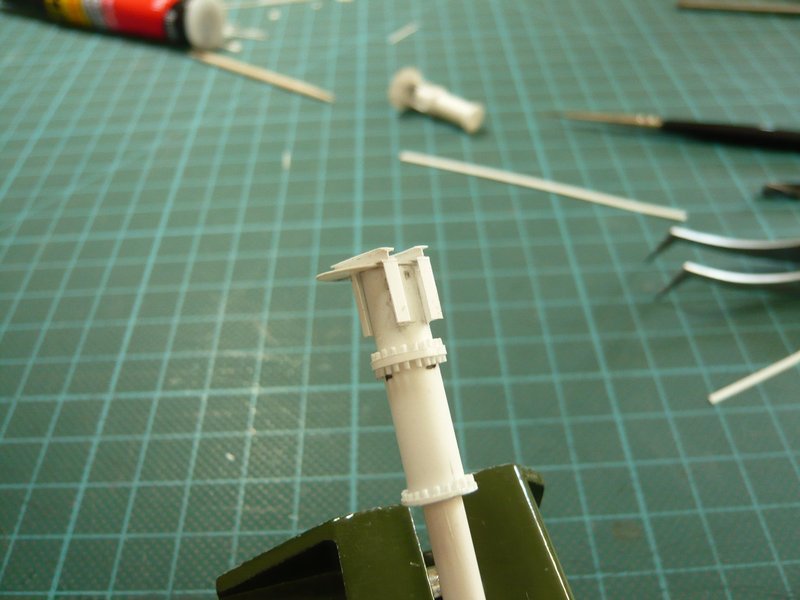

Since the next narrow retaining strip has offered too little support for the last bending,

a stronger Balsa board had to be used.

But with it then also the last bending has worked well,

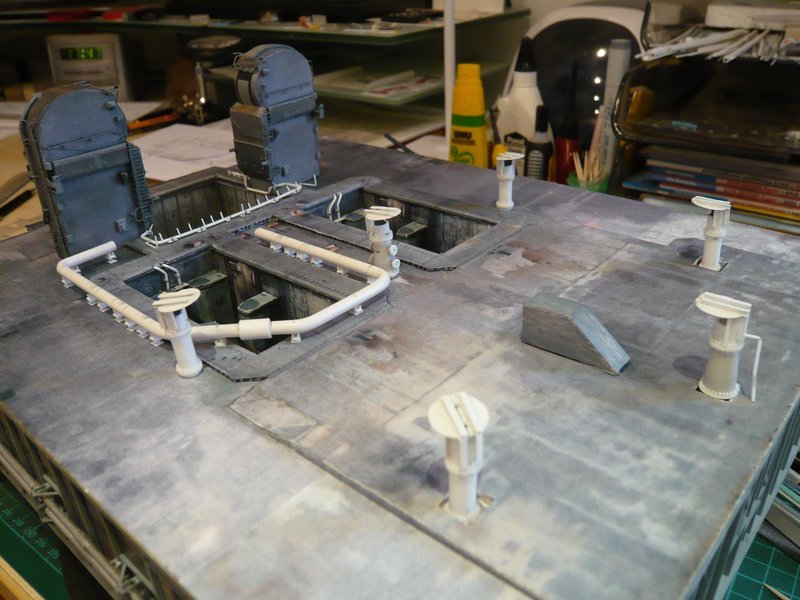

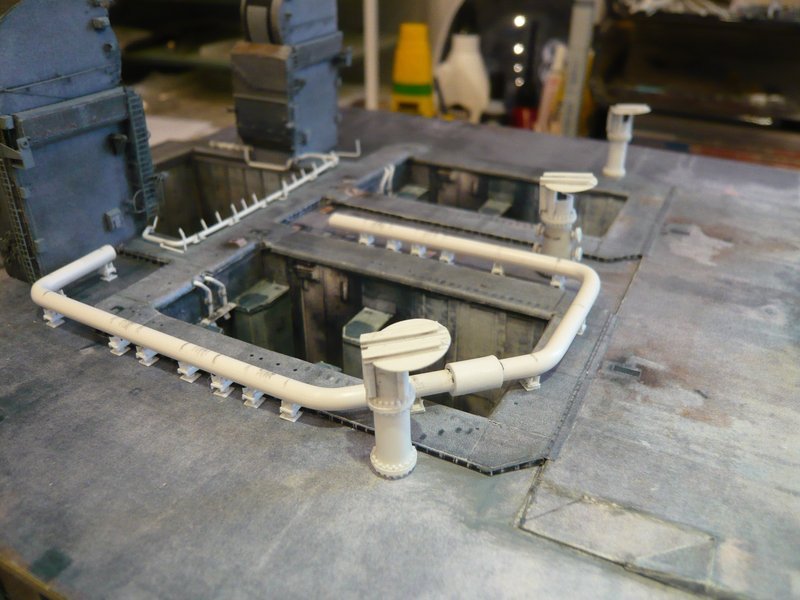

so that the ring line has remained dimensionally stable even after removal of the outer corset rods, what eventually was meaning and purpose of the whole exercise.

Okay, if you look closely, you can see that the last area still has a minimum curvature, which can still be smoothed.

And because everything works the way how I had imagined, I can also quietly bend the second ring line.

![]()

![]()

![]()

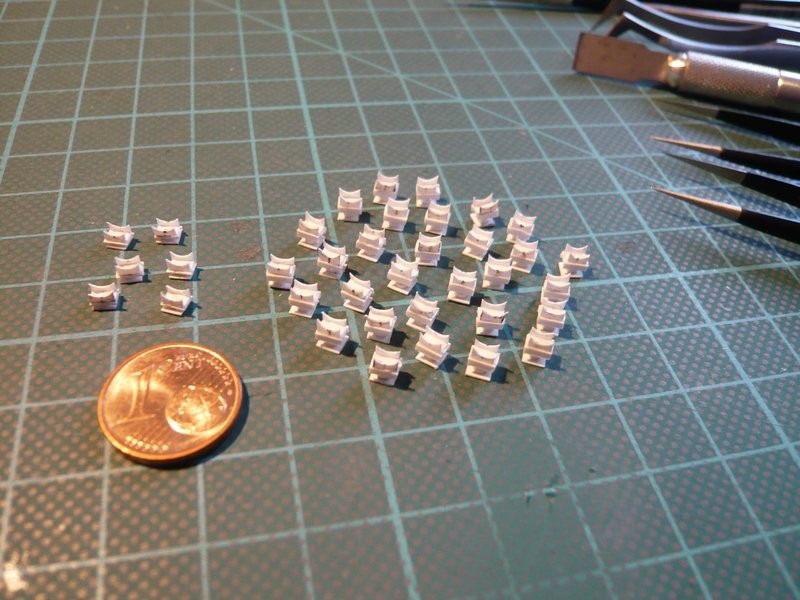

![]() as you can see here in the photo with Andrew Scheer.

as you can see here in the photo with Andrew Scheer.

![]()

![]()

![]()

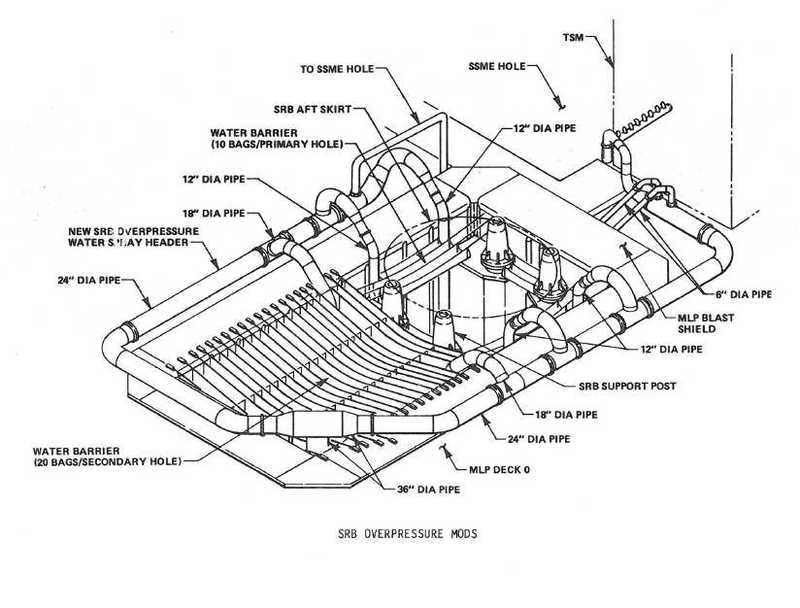

And I’m very satisfied and mean that they fit quite well.

And I’m very satisfied and mean that they fit quite well.

Therefore one should then align the rod preferably immediately and over the entire length at the next edge and fix it in this position until to cooling down.

Therefore one should then align the rod preferably immediately and over the entire length at the next edge and fix it in this position until to cooling down.