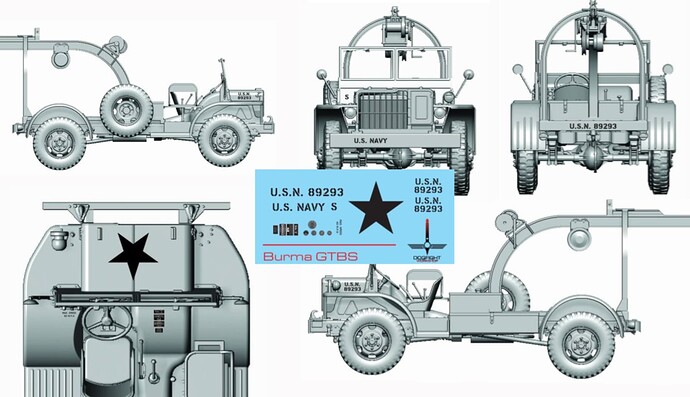

My decision to build the M1 Bomb Truck using the Ford truck and the Chevy M6 Bomb truck has led to what the Army likes to call “second and third order effects.”

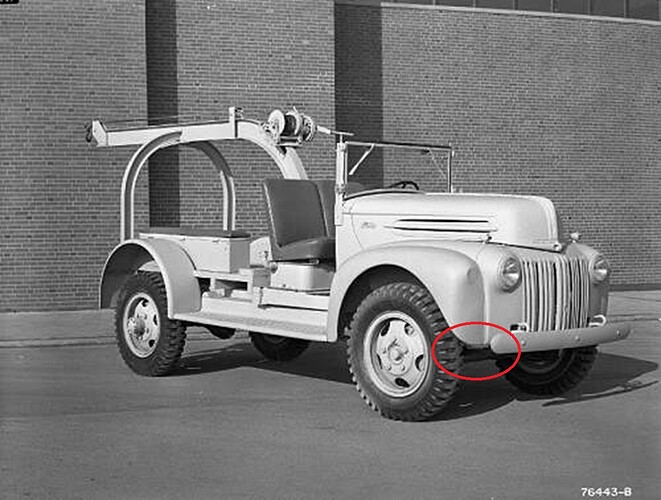

The first thing I discovered is that the Navy, unlike the Army Air Corps, did not feel that four wheel drive was necessary for airfield duty. An odd decision given some of the conditions and locations of Navy airfields in the Pacific. So the whereas the M6 Bomb Truck has four wheel drive, the M1 does not:

I decided to kitbash these kits by mainly using the Airfix M6 kit with a modified Ford cab. I can use the Ford front axle as well. That means that I have a left over Chevy differential (pumpkin) with the distinctive ribs on it.

You might recall my G7107 conversion above in which I commented that the rear pumpkin would be incorrect. Now I can fix that. I just have to center the pumpkin in the axle.

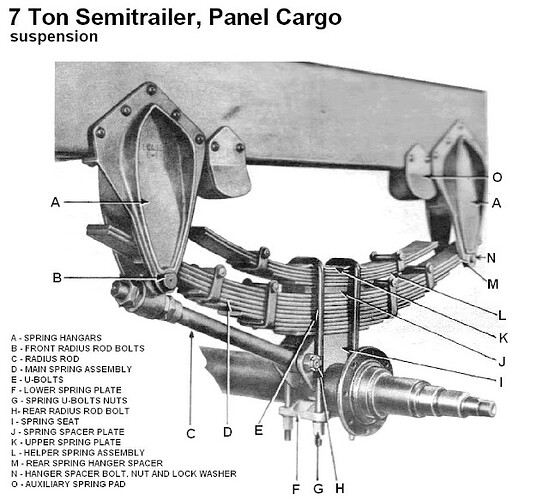

The next bit of luck was the rear springs from the Ford truck that I would not be using.

After a little alteration, these:

Can be used for this:

And finally, the other part of the G7107 build that bothered me was its rear springs. I had to try to cobble together springs for a single axle from springs for a double axle:

The results were not pretty:

I tried to tell myself no one would really notice, as with the differential. But I notice, and it bothered me. Now I can use more appropriate springs left over from the front of the Ford.

Now on to building. The Ford cab was a bit of a disappointment, the PST kit actually supplies a cab from another one of their kits that you have to remove the side hood panels from.

Once that’s done you’re left with an incorrect door angle. But since I’m cutting up the cab, I have to remove that seam altogether. Once again, my favorite method - CA, accelerator, sand - takes care of the problem in less than a minute.

This:

To this:

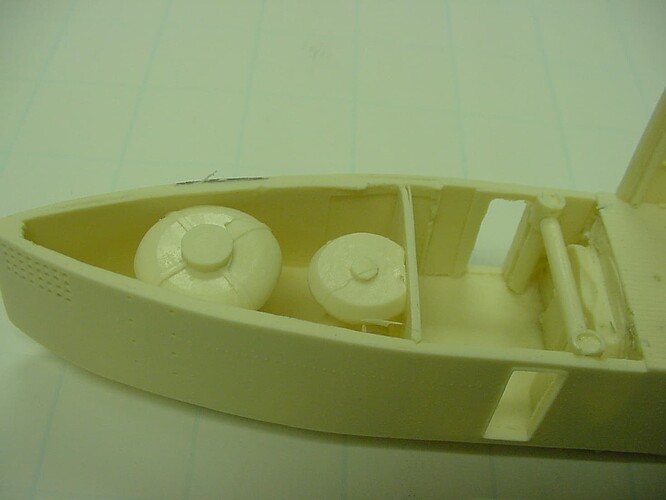

After cutting the cab I discovered none of the PST parts work well with each other. The upper cab, lower cab, and floor don’t fit together at all, So I just temporarily glued the lower cab to the Airfix frame to see how things would look, At this point I was more concerned with getting the frame level front to rear. The frame is level, but that Ford axle looks a little low, even though where it is puts the front wheels at the right height. At this point, the fenders still sit too high over the front wheels, so maybe lowering everything will make the axle’s position look better. Also, when I actually cement the front of the lower cab to the frame, it will sit level. The part has a slight warp that goes away.

The whole thing starting to come together:

I’ll need to extend the rear fenders on this ford version by splicing fenders together from two of the Airfix Chevy kits.