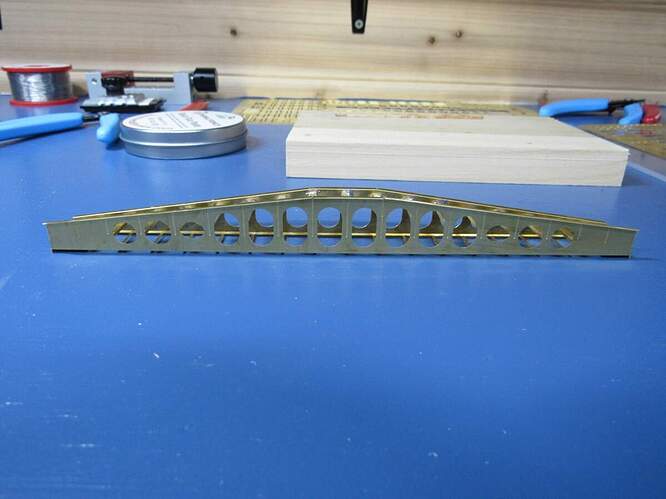

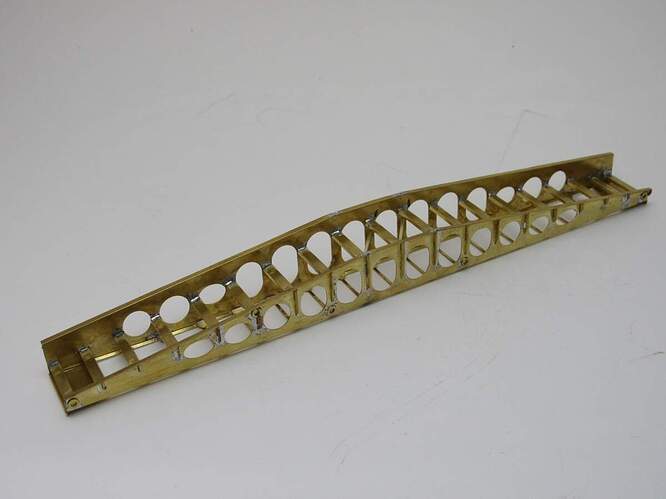

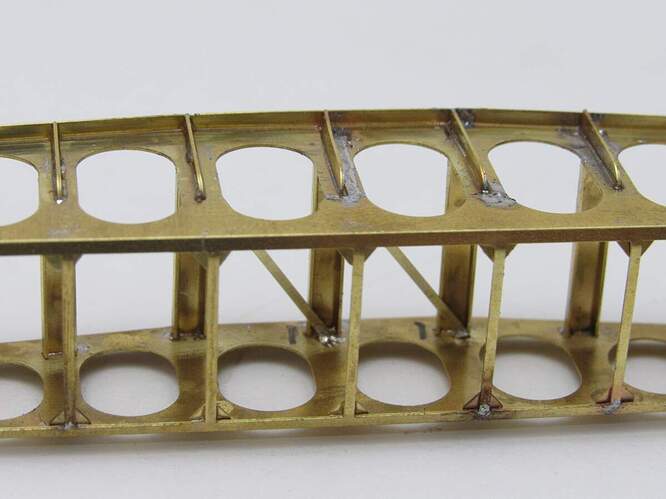

So that’s what I’ll be trying to build. The idea has been kicking around in my head for years now, and a long while back I even tried doing this with styrene. Cutting and sanding all those holes out got to me and it was scrapped. But now I’m back, with a new plan: Custom Photo-etch.

I had plans and pictures already collected, so those were ready to go, but before I could dive into design work, I wanted to have the donor kit on hand to properly scale the drawings I had found.

The donor kit. Posted a few weeks ago in the postman thread. I went ahead and built up the hull last weekend (no pictures, but I assure you it’s not all that exciting). Turns out my plans were scaled a couple mm’s off, so good thing I waited.

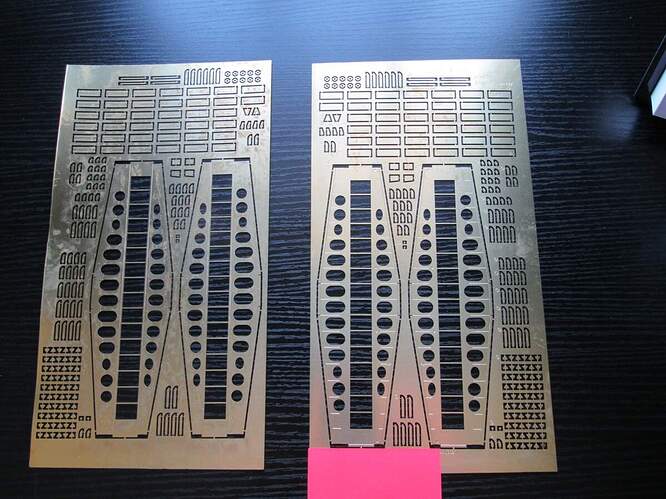

Custom PE was an option that hadn’t occurred to me years ago, but I figured there must be something out there, so with some searching the only company I found that caters to the hobbyist (or even mentions them) was PPD over in Scotland. They have some helpful guides on their site, so following those I dove into the design work.

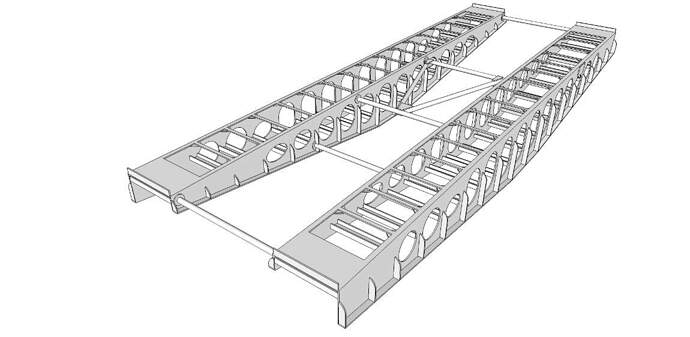

Of course I needed to double my work load. I decided to rough out the dimensions in SketchUp, matching up with the plans, and making sure everything fit together. As I made or edited a piece, I’d jump over in AutoCAD and draw it out in there too. Can’t think of a better way to check my work so this will have to do for now.

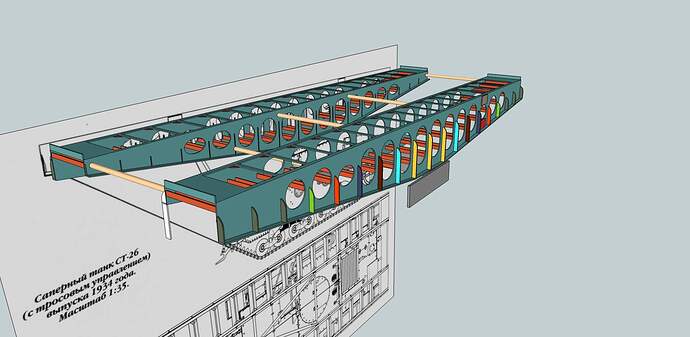

Here’s where I’m at in SketchUp,

Don’t mind the rainbow colors, just making each part number a different color for ease of counting totals and for what goes where. An exciting way to spend Valentine’s day.

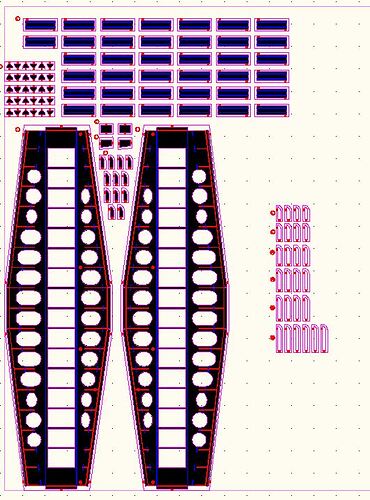

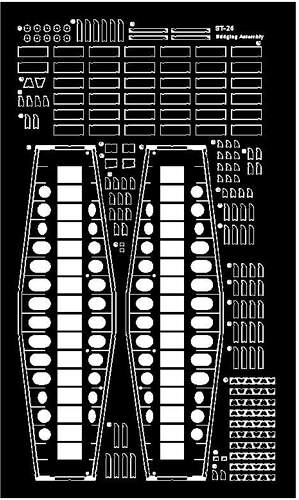

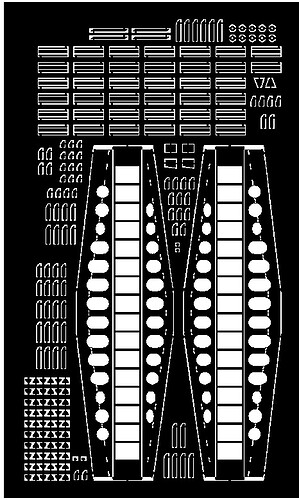

And here’s the translation in AutoCAD so far,

It’s gettin there. I’m thinking of doing this in two frets, one for the bridge itself, and the other for the hull mounted parts (this way I can order one sooner). Design wise, I’ve also been leaning more towards photos instead of taking the plans as gospel, so there may be some differences there. 100% historical accuracy won’t be happening here unfortunately, just not enough for me to go by, but I think I’m close.

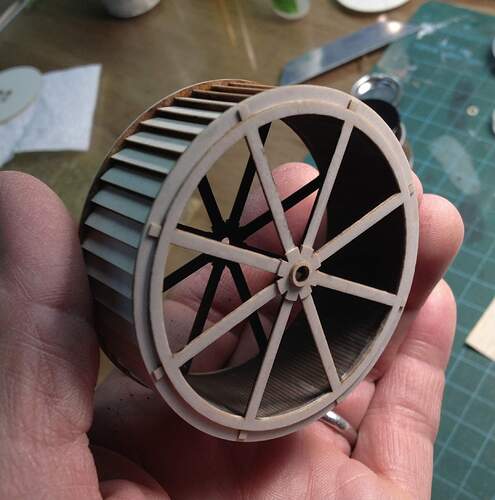

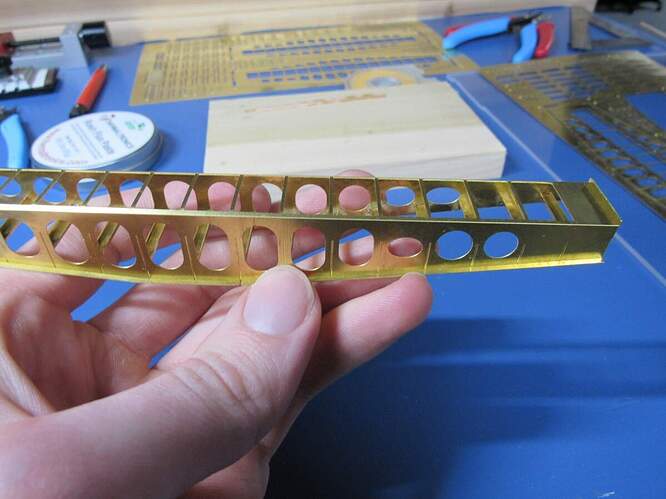

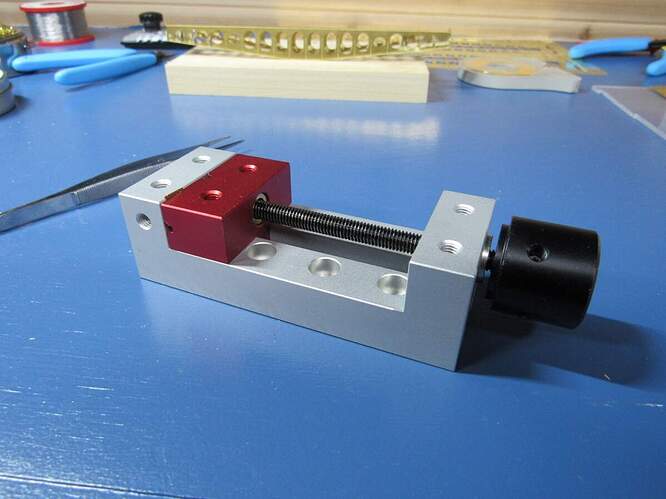

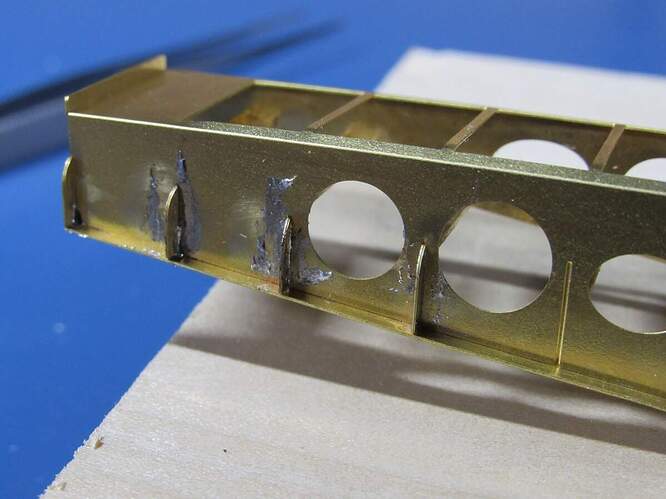

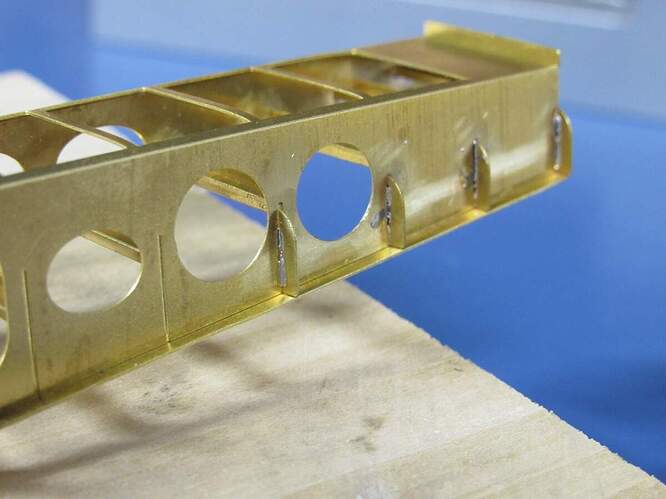

This is all a first for me. I’ve never designed PE before, never used PPD (and who knows what shipping will be like now), I also want to solder this together, which again, is something I’ve never done. There’ll be a lot of learning here. It will also be slow going, so this thread might be a bit premature, but I wanted to share it. Excited to get folding and soldering, hoping to have the bridge design complete and ordered by the end of the week.

Thanks for looking in.