Sporadic work sesssions before the 4th. I did get to test fit the engines into their housings and continued building up the engine shrouds. I have to paint things before going further.

The instructions don’t tell you if it’s better to glue these two parts together before or after attaching them to the shroud base. Because of the critical nature of the fit, being a long edge with no tabs/pins, I chose to glue them now. Glad I did as it’s much easier to fit them on the shroud base when they’re together. The joint is basically invisible.

I also glued the opening portion of the shroud that serves as a work platform. It was a challenging joint with very little surface area. I let them dry for days and they’re nice and secure. The prototype photos shows aluminum-faced batting in the square spaces n the door that is probably heat insulation. I’m going to simulate that with Bare Metal Foil (after painting zinc-chromate green on all the rest of the insides.) There’s another frail “telescoping” support pole that connects these two parts. I may make it out of metal since it looks very prone to breakage.

I test fit the shrouds (before gluing the doors) to the fuze. They needed a little relieving on their rectangular pins to they weren’t a press fit. Press fits are bad when you’re gluing delicate assemblies.

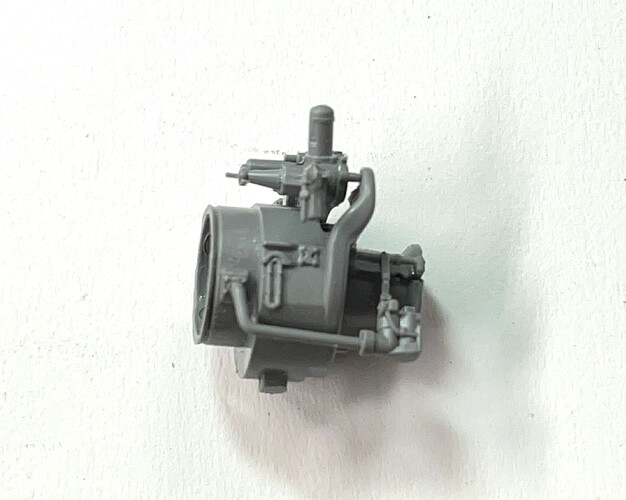

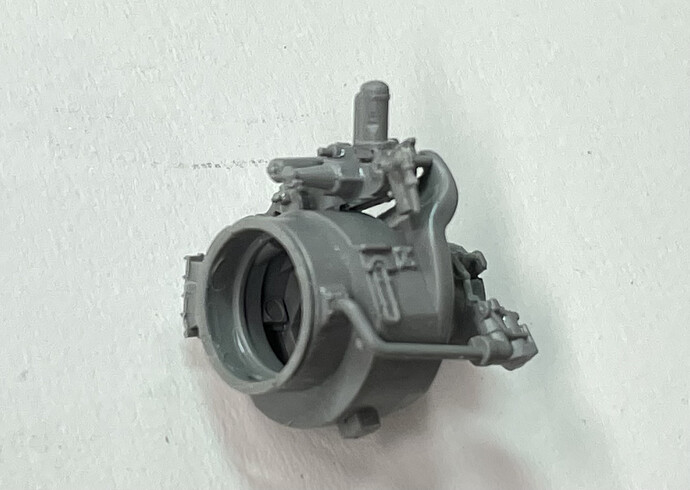

The engines engage the slots at the bottom. Before they go in, besides paint, there are a couple of unseen details that go in under the engines. Shrounds are not glued in.

There are also two, frail plastic bars that tie the exhaust coolers together, one on top and one on the bottom. The gluing surface to the tiny bit of styrene that’s sticking up was way too small for a good joint. Before gluing I had to pull the three manifolds together and CA them so they were touching. Otherwise, the bars would not align to their pins. I then used Tamiya cement and followed up with med CA. The long one, engages in a hole in the fuze. The short one looks like its end glues to the upper shroud assembly.

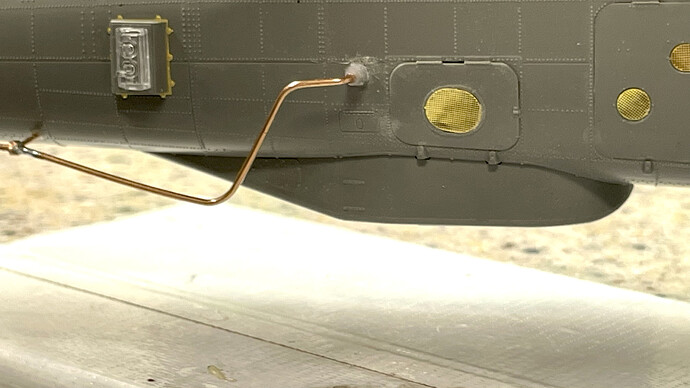

You can see where this bar engages the fuze. Nothing glued… all test fit.

With both engines fit it looks very busy.

I have another “commission” project for my wife’s cousin. Found out recently that he was a flight chief on a P2V-5 Lockheed Neptune during the Cold War. I found a Hasegawa kit on eBay and will build it to his plane’s id.

Decals were very, very old and yellow so all need to be redrawn and reprinted. Not being able to print white, and using white-background decal paper, means that white lettering either has to be individually hand cut and placed, or I have to match the glossy sea blue background and have the lettering connected with the background color. I’ve done this before with decent success. it just takes a lot of fiddling with colors on CorelDraw to get a match with inkjet ink. I make color swatch sheets to do it. Last time it took 14 test colors to get it close. If I use Vallejo Gloss Sea Blue, I already have a match for that color. I don’t like Vallejo since it takes so long to dry. I’m thinking about using Mission Models colors. Not sure I’m going to post this model.

Here are two pictures of his actual plane. His plane was the one that tested the nuclear depth charge in the early 60s. Historic!

It DID NOT have the top gun turret.

The Neptune was one of the first Piston/jet craft made along with the B-36. The piston engines were the amazing Wright R-3350-30W. These were the final evolution of radial engines with turbo-compounding. Instead of using exhaust to drive a supercharger (turbocharging, the three turbines were geared directly to the crankshaft through a fluid coupling. They created an additional 500 horsepower. There’s a cutaway version of this engine at the Franklin Institute in Philadelphia that really impressed me as a kid. I had no idea how special that arrangement was. The three exhaust stacks spaced around the nacelle equally (180º) is one of the ways to identify this engine. The engine produced 3,700 hp with the same fuel consumption as the ubiquitous R2800.

This engine was also found in the Lockheed Constellation, the DC 7, and the Globemaster 1 cargo plane. The B-29s had the 3350s (along with the A1 Skyraider) but they weren’t the turbo-compound model. 3350s were also one of the first engines to have direct injection into the combustion chambers to rectify the fuel imbalance problems. There’s a nice docuementary on this engine. It was a monster to perfect an there were 8,000 engineering changes before it finally proved itself. And it did! They make over 8,000 of them.

Being a flight engineer on these piston/jet planes must have been wild. They used the jets for take off, and had shutters that closed them off during cruise so they wouldn’t windmill.

Okay… enough digression. Every one who celebrates have a safe and happy 4th of July Holiday.