Super! ![]()

Masterfully done.

Looks bloody brilliant! ![]()

—mike

A Spit is always a looker! Well done, Erik! ![]()

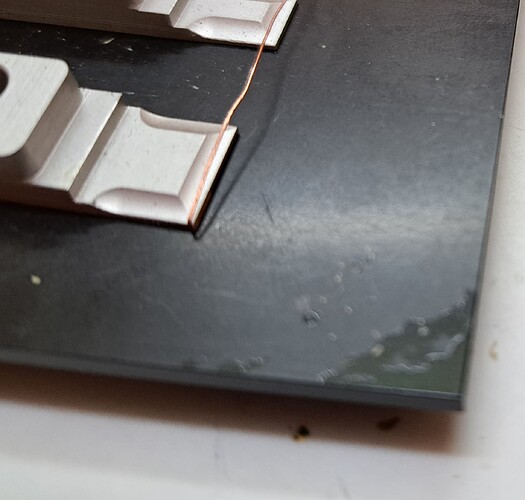

I re started my airbrush spray booth project, I say re started because originally I was using foam core boards, but gave up on that material due to fitment and strength (or more precisely the lack there of) of the material. This round I used corrugated plastic sheets. They’re actually lighter but far stronger than the foam core. Another benefit is they’re waterproof.

In the end this spray booth will have two 140mm high static pressure computer fans, giving me around 200-240 cfm total air movement. I have led light bars and filter material (sourced from Home Chef freezer box insulation (spun fiberglass 1.5 inch thick) and a second layer of carbon filter. To keep everything clean I plan to line the spray area with freezer paper that I can change out as necessary.

The booth is 19" wide x 13" tall with about 15" spray area depth. That is a 32 inch monitor behind the booth for reference.

I do hope this is 1/16 scale… you’d go mad otherwise… or still…?

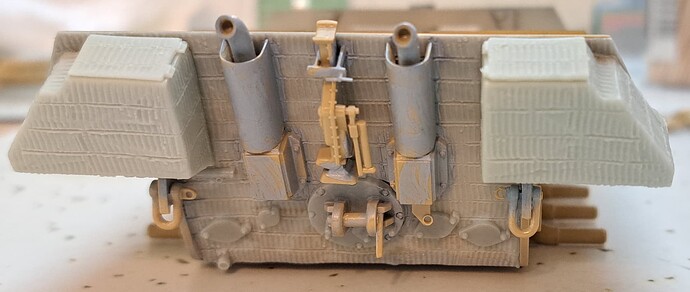

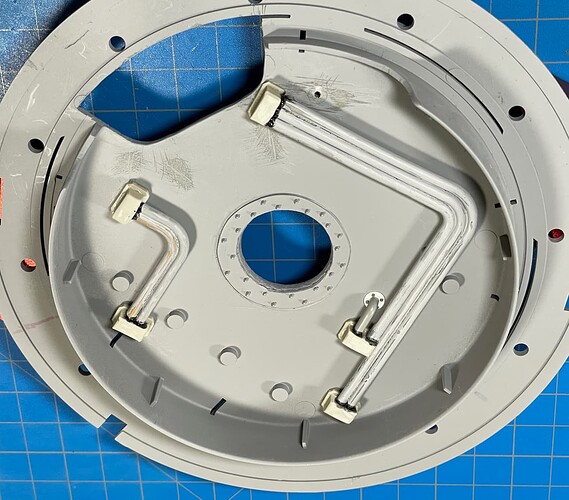

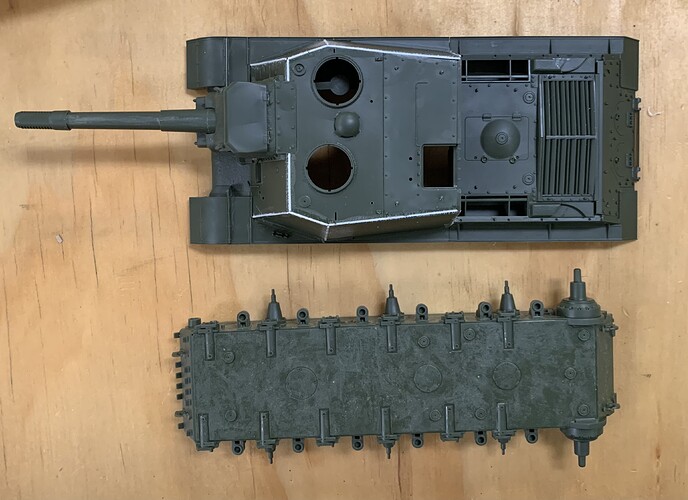

Ron, the Panther is 1/35

My display area is sadly too small for 1/16 projects.

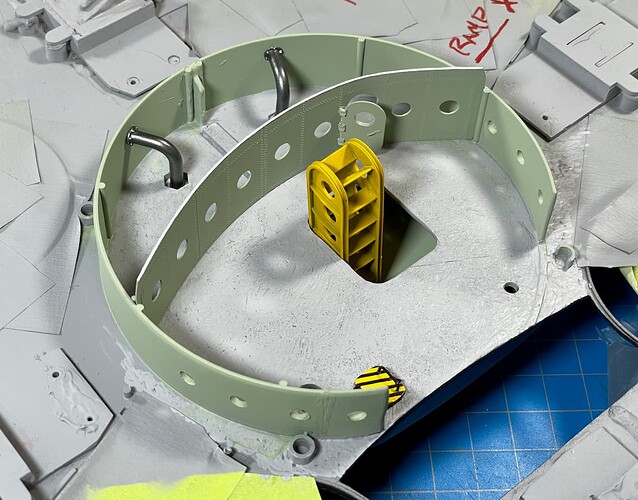

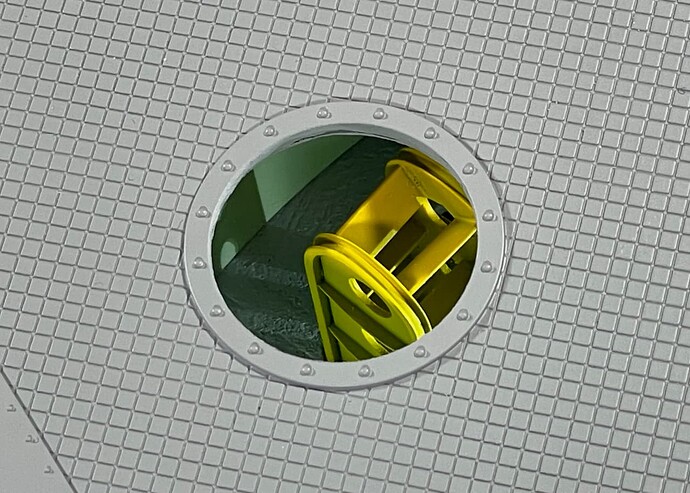

Greebling and groveling above and below deck…

Bomb Room ceiling… 🫨

Bomb Room… ![]()

![]()

A view from the Bridge… ![]()

Thank’s for having a look!

—mike …![]()

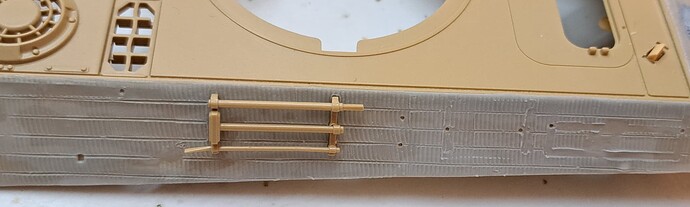

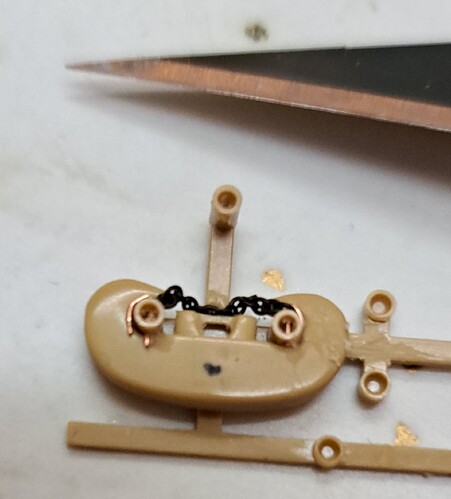

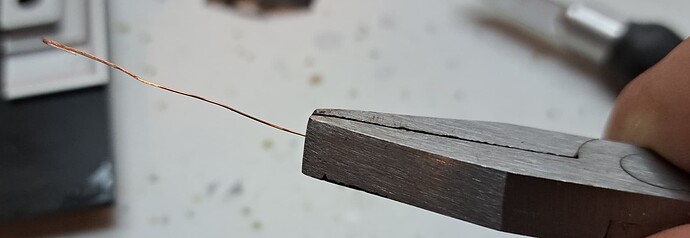

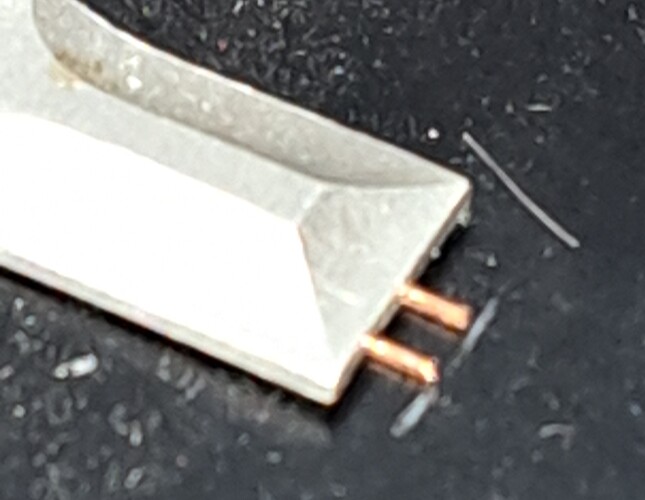

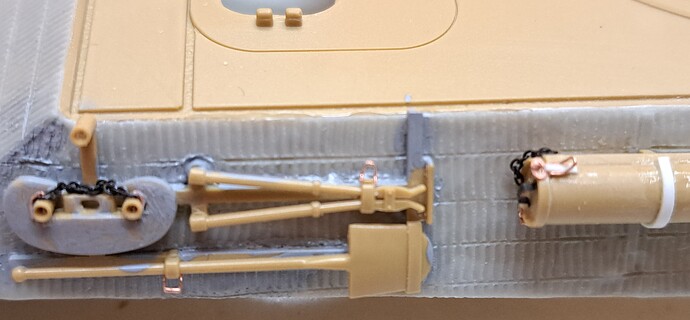

Today more 1/35 Panther fiddle bits. Skipped the PE for the tools, went old school.

Crimp beading wire flat

Bend to shape

Cut to size

Bend to final shape

Add tool clasps

Installed tool rack

The 1993 era Tamiya rack proved easy to work with as the three pipes on the left side are already hollow.

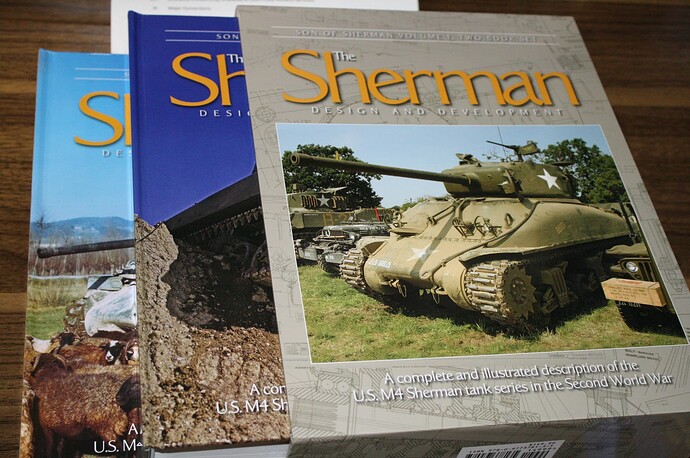

The day wrapped with nice surprise.

After a long absence from modelling due to a summer job, made the genius executive decision to start doing the tracks on a T-55AM that I started before the break. The tracks have 3 sprue attachment points, 2 pin marks, and require the insides of the track being filed to fit the links before it. All in all, not the best thing to do as my return to the hobby.

Started a 1/72. Special Hobby DH. 100 Vampire Mk.3 this evening. When finished it will be in Norwegian markings.

ahhh!

But once you have those tracks finished you will feel invincible and able to tackle any kit

![]()

![]()

Ryan, the JSU-152 is looking good!