Forget soldering PE parts, John, for this you should use Gator’s Grip.

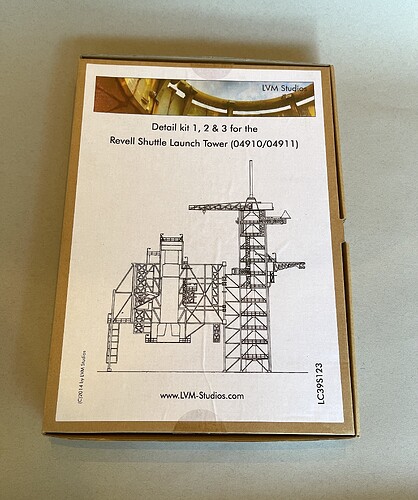

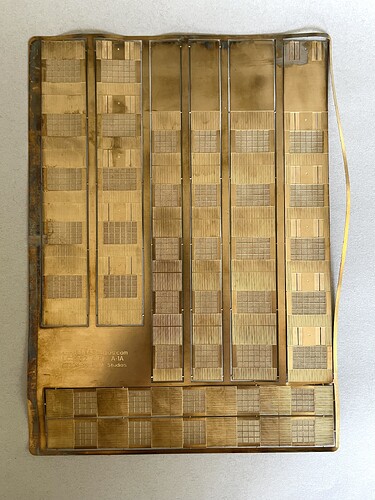

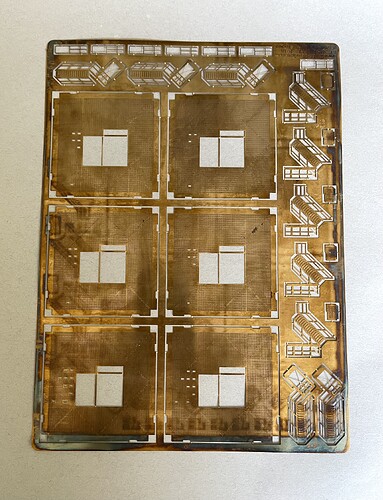

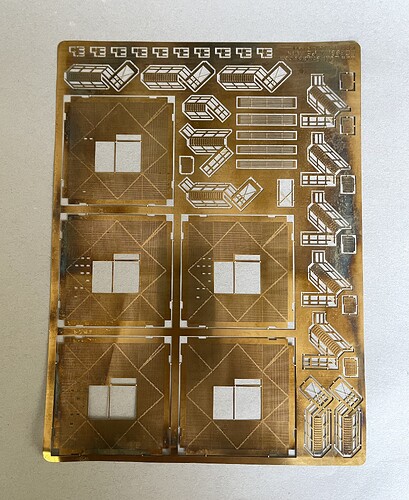

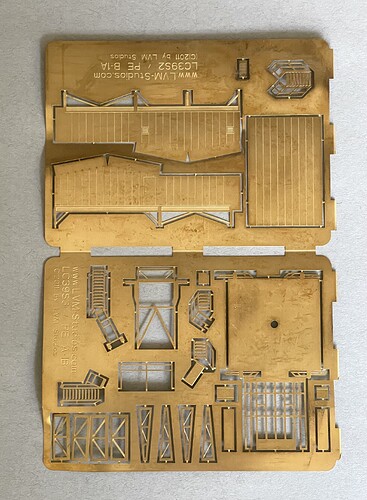

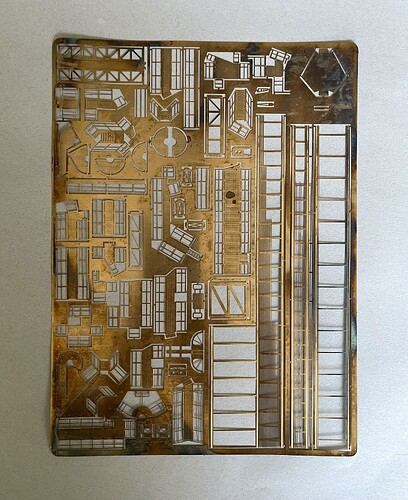

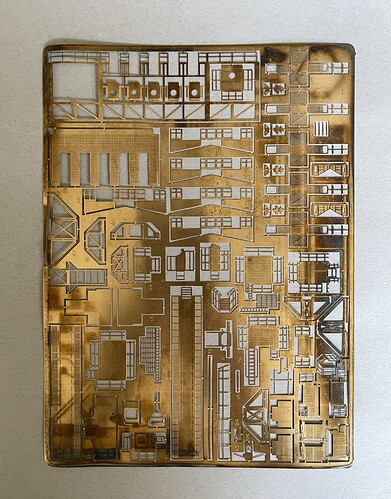

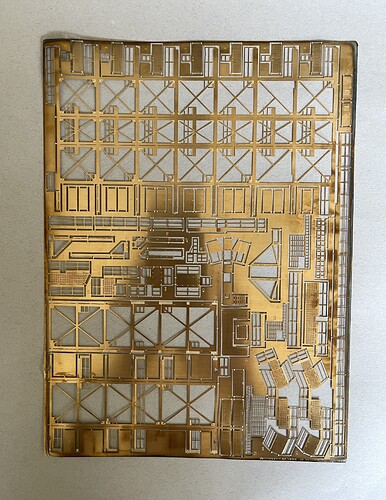

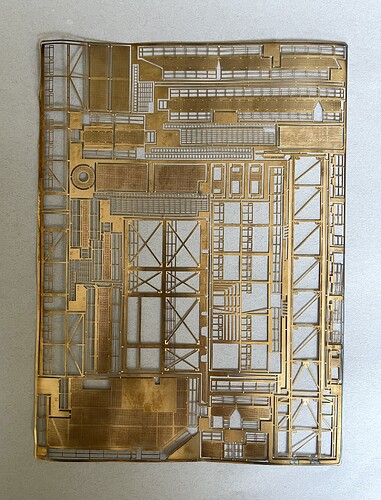

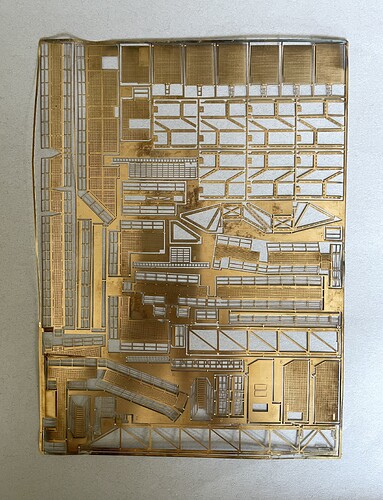

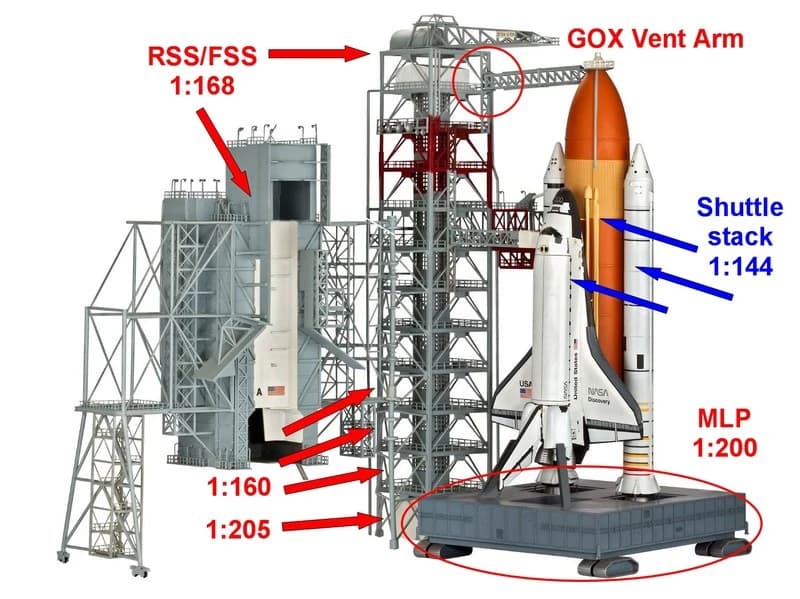

First I had only intended to use it when gluing the various LVM PE parts of the FSS/RSS and therefore lost sight of something.

A major advantage of this glue is that it is water soluble and does not harden as quickly as CA. This allows you to correct the fit of the parts for a while. During this time, the initially milky white color changes to transparent, giving an indication that the glue is dry and hardened.

Another advantage is the amazing elasticity of the adhesive in the solid state. While a contact glued with CA can quickly break off and become brittle,  the Gator’s Grip contact itself should be able to withstand a 90° bend and then straighten itself up again,

the Gator’s Grip contact itself should be able to withstand a 90° bend and then straighten itself up again,  also known as Memory effect, which I of course know as a former materials researcher, but which I almost didn’t want to believe at first with this PE stuff.

also known as Memory effect, which I of course know as a former materials researcher, but which I almost didn’t want to believe at first with this PE stuff.

And this behavior I had tested already longer time ago (2017).

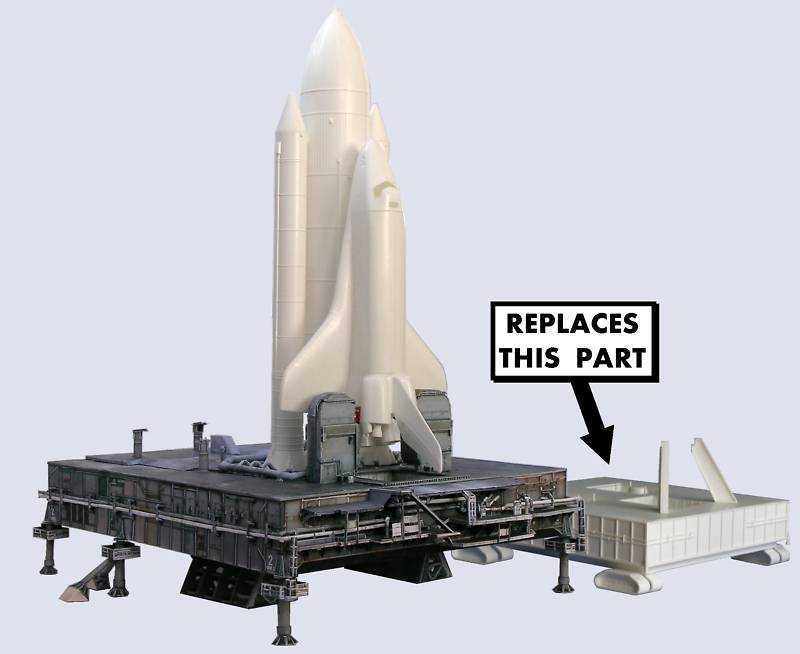

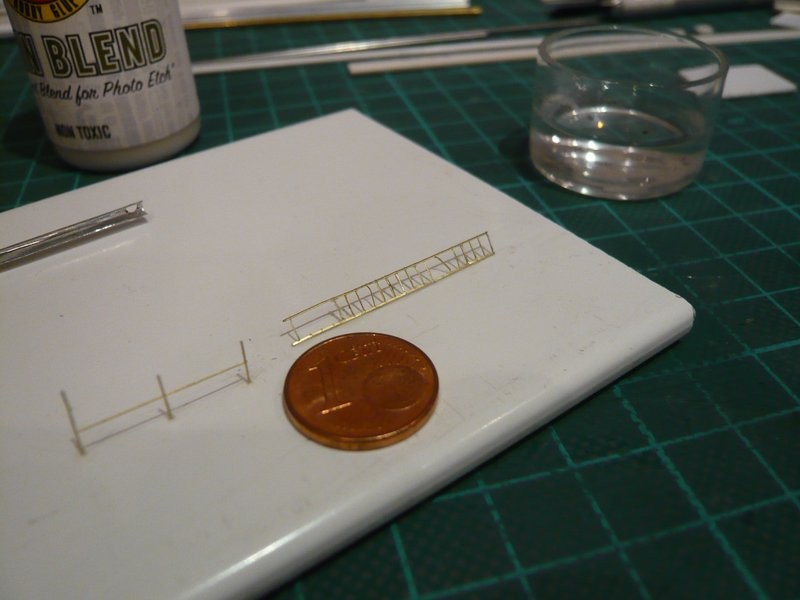

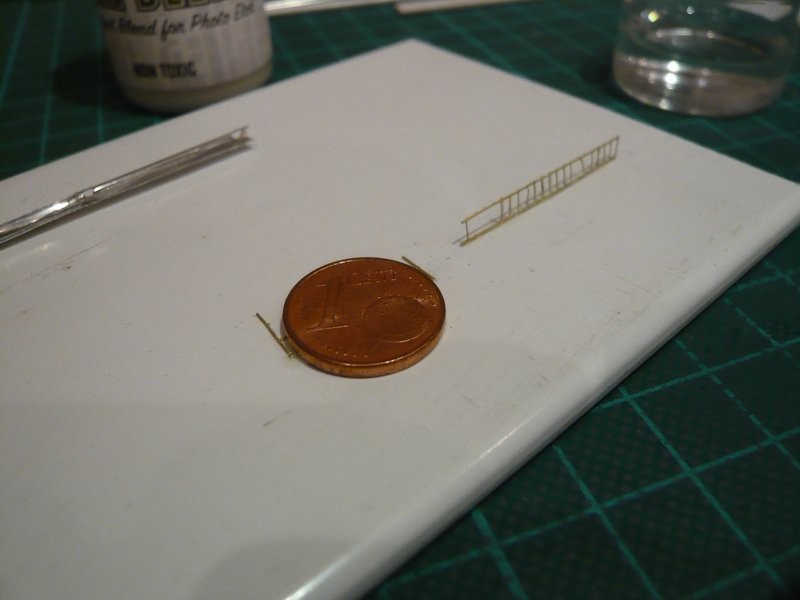

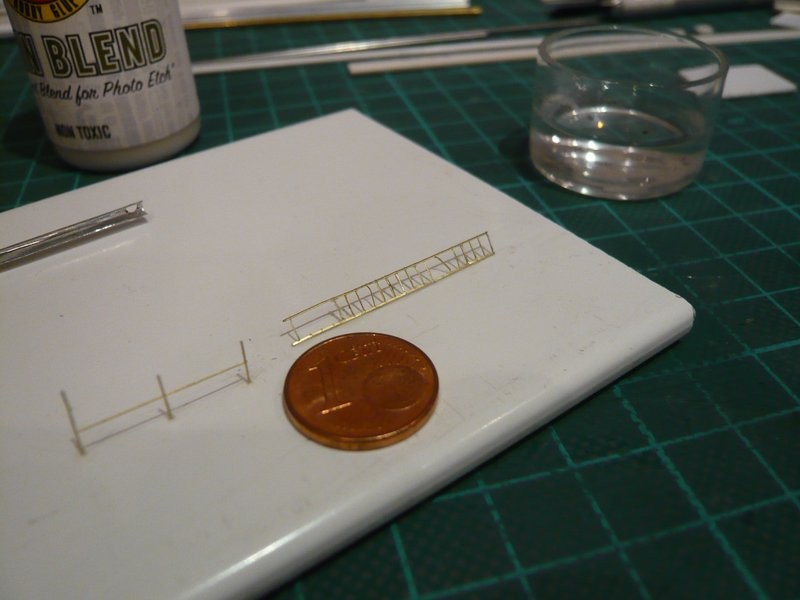

In addition to gluing the gutters at the MLP deck, I also glued an old PE ladder and a piece of railing upright to a plastic base and let it dry.

And then came the brutal acid test for the ladder by putting on tweezers, which had flattened it.

And believe it or not, after removing the tweezers, the miraculous resurrection of the ladder actually began, here halfway through the recovery from this exertion,

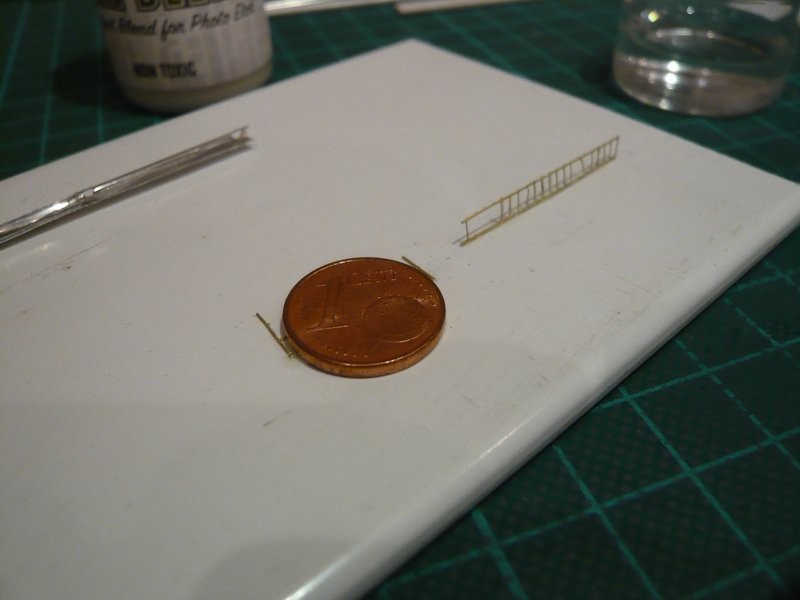

and then almost to the starting point.

And the railing finally had to bow to my cent dime,

but surprisingly had the same qualities and gradually got back up, although these are only point contacts!!!

Finally, here is the condition of the subjects after this stress test, which impressively demonstrates their total recovery. Heart, what do you want more?

As a conclusion, I can rightly say that the test reports didn’t promise too much and that Gator’s Grip is really a devil’s stuff that convinced me and will help me when gluing further PE parts.

![]()