Svt40 on my thread in the FSM Forum posted this great image showing the inner details behind the tail rotor housing and details of the index motor head.

I used the tail rotor image to create a index motor head. I didn’t go the full route with the roller and pin, but it’s shaped so it fits the crown on the tail rotor rear. I was wondering why that part was shaped that way… now I know. (and so do all of you). Looking at this close up, it’s still a bit big and I can reduce it.

We’re at the stage of the model that’s equivalent to the punchlist phase of building a new house. The last little bits and pieces take an iordinately long time. Another thought I have is just how much more complicated the helicopter became when they turned the Blackhawk into the Seahawk. All the folding stuff adds mechanical complexity AND sensors to ensure that the flight crews knows everything is in the right place. Blackhawks don’t need a blade indexing motor.

I started cobbling together the tail plane lock bars. They attach to the hinge point on the tail plane and clamp to the edge of the center section. I added doublers to some styrene stock that I’ll shape to make the contours more like the real ones. They have to dry overnight since when I tried to shape them before they were fully dry, they didn’t like it.

I also had to add back a hinge point so it would have something to hold onto. The kit’s part disintegrated when I had to rip off the already-glued tail panels.

I started painting stuff! This is a milestone. I painted the tires rubber black which finished the smaller tail wheels.

remember I made some round masks for the small wheel hubs a while ago when I painted them white.

But for the large main wheels I didn’t paint and mask the hubs first. The tie-down ring protrudes from the wheel and I didn’t want to break it by masking on top. In this case, using the same dividers with one leg sharpened to a chisel edge, I cut the circles, but used the piece with the holes.

I then sprayed them a base coat of lacquer, in this case some Tamiya silver, and I go back and paint the while. The lacquer acts as a barrier and prevents the black from leaking through. I always put on DullCoat when I’m going to change colors and don’t want any blending.

The last things I painted was the exhaust chutes. I first shot the turbine outlet some dark iron and then went back and did the whole area with flat black taking car to not overcoat the previously shot dark iron.

This is flash shot (which I rarely use) that lights up the innards.

And here’s a non-flash shot showing the whole area. This will be masked to the proper outlines as needed. The last thing I did was shoot this paint with DullCoat to seal the black and make good base for the body colors. BTW: that chute where you can see a little bare color is the APU’s exhaust which would be in that part of the overhead.

I have to write a real punchlist to ensure that I don’t miss anything. It’s a relief that all the ResKit work is now complete and reasonably successful. I still have to solder together the rear view mirror brackets, which I’m doing tomorrow.

I also glued on the big radome on the bottom since it was time.

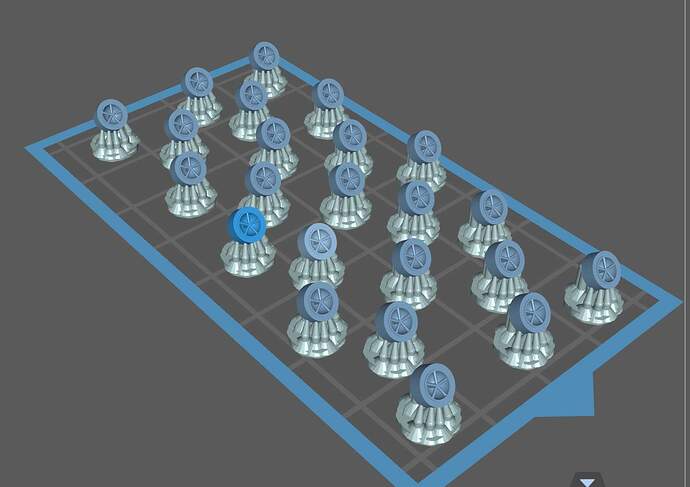

I need to build a base and want it to duplicate the surface of a hangar deck. I’m going to 3D print my own tie down cups. They’re available from Reedoak, but they’re expensive and I want to keep my powder dry to buy their 1/35 Naval Aviation service people.

What is the diameter of the modern USN tie down cup?

Found out…. 9.8" and made the drawing about 20 minutes and can produce a ton of them for $0.25 of resin.

Now I just have to the rest of the design.