I took your advice and built the fuel tank. It will go on one side and the torpedo on the other.

Today was a milestone day with the panel accenting, flat coat and unveiling of the glazing. I got a got set of prints, but they’re too thin. I got the profile dead on, but the depth needed some shimming.

Here’s the comparison to the original

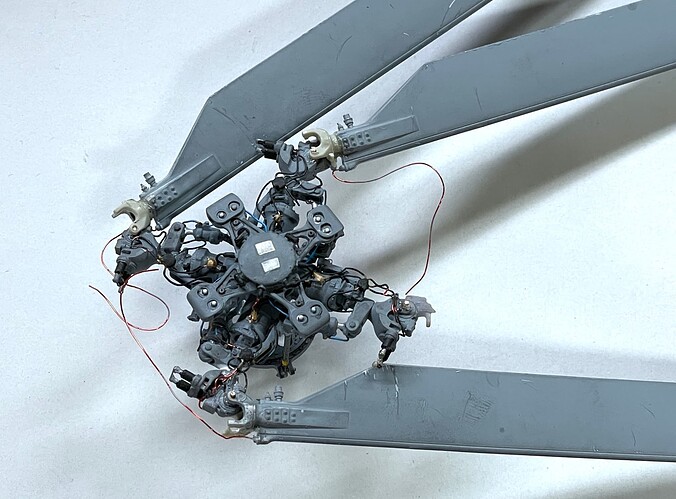

After fitting it on the hub and blade I found that it was about 0.040" too thin and used some styrene CA’d in place to do the job. It all fit nicely.

It all fit nicely until, both eyes fractured when I put a little bit too much downward pressure when fitting the hub on the craft and trying to determine how much droop the back two blades will have to have. I will epoxy the blade without the full eyes and then use some Bondic to reconfigure the contours.

I used the Tamiya Black Panel Accent to highlight all the doors, seams and compartments this machine has. It looks pretty awful when you first put this stuff on. You have to let it dry before removing the excess.

The bottom had a lot of places.

I use the traditional Q-tip lightly dampened with low odor mineral spirits. I was annoyed that the mission paint dissolved in the mineral spirits. That’s not supposed to happen. Tamiya paint DOES NOT. Also on the bottom, some of gloss coat was not sturdy enough and the accent leaked into the flat paint underneath making clean removal of the excess difficult.

But, with all of that, the final results after shooting with Tamiya clear flat boosted with a bit more flat base, came out pretty nicel

There will be more dirtying the bottom with pastels since even on clean Seahawks there enough stuff being discharged from various vents to make things interesting.

I actually almost blew by getting all set up to spray the flat only to realize I didn’t do any of the panel acccenting. You can’t do that on a flat finish. It makes a mess.

After the flat dried it was time for the “great unveiling”. I took the tape off all the glazing. I was worried that the canopy cement might not have enough grip to resist the pull of the masking tape and I hate when my worries come true. The first window I de-masked popped out. it was the window in the sliding cabin door so I was able to put it back carefully using solvent cement. All the other windows de-masked without problem except for the co-pilots door. The tape was too tight, especially where I sealed the edges with clear gloss.

That window got damaged. All the others are perfect. I put on several coats of Pledge with Future floor wax and hope it will be okay. There are two other sets of cockpit doors, but they are not for the SH-60B. The “B’s” window has a curved notch taken out of it, while the others are straight. If this window is too damaged, I’ll make one of those work.

Here’s the glazing exposed. It’s nice to see the engine again. I missed seeing it.

I did a few more punchlist items. I filled the hollow rear-view mirror housings with Bondic and then painted them with Molotow Chrome. Decanting the marker was one of the smartest things I’ve done in a while. It’s really slick to be able to brush the paint where you want it. The felt tips work good for the first application, but make a mess if you have to go back and add more. I also used the same to paint the oleo strut on the main gear. There’s still some more tiny paint jobs that need doing and that will wait until Monday.

Above the oleo strut is an elastomer bellows. That will be painted rubber black.

I also did the back painting on the sonabuoy noses and they look good now.

The model proper will be done some time next week. The base and figures are still out there.