I do actually build my own stuff, in addition to shepherding the “epic” B-17F 1/48 Luscious Lady build to the finish line.

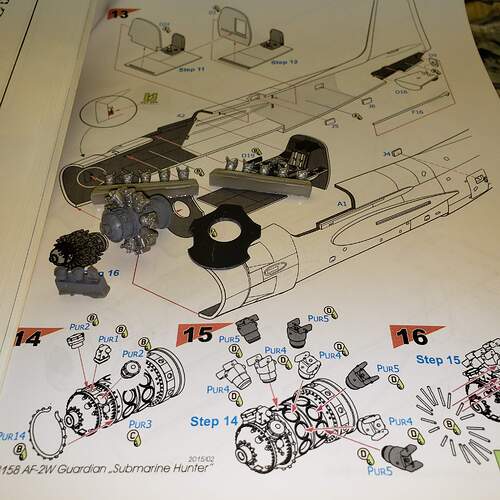

This build is of a Special Hobby 1/48 AF-2 Guardian in the “Hunter” configuration. I had entered it into the old forum Korean War campaign, but the build schedule meant it really was “never gonna happen” for me. ![]()

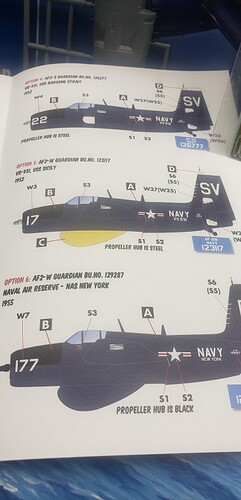

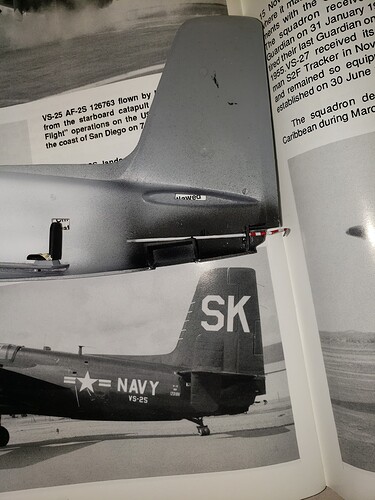

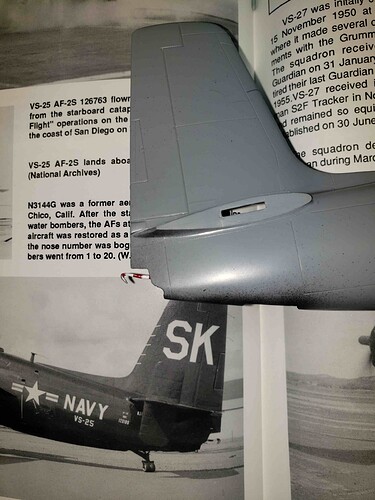

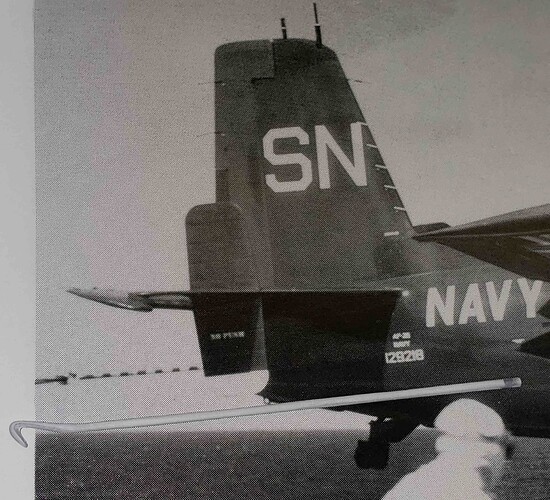

Anyway, here is the specific subject.

which belonged to VS-931, assigned to various carriers during a deployment to Korea in 1952. Here’s a brief history of the squadron that I found online.

VS-931 Antisubmarine Squadron was activated at Willow Grove Naval Air Station in Pennsylvania on March 1, 1951, during the Korean War and was transferred to Los Alamitos Naval Air Station in California. The squadron was sent abroad on the USS Sicily and operated near Japan and Okinawa. Upon transferring to the USS Badoeng Strait, the Squadron went to Korea on two different occasions to protect the US Naval fleet from enemy submarines. There were several transfers back and forth between the two ships and in addition, the squadron was stationed on land bases at Atsugi and Itami for brief periods. The squadron returned to the States aboard the USS Sicily. Upon returning to Los Alamitos the squadron’s designation was changed from VS-931 to VS-20.

There is no doubt that VS-931 took part in ASW missions in support of the UN Korean war effort, as documented by this online history of the USS Badoeng Strait (CVE-116)

Badoeng Strait strait made two more Korean War deployments, in October 1951 - February 1952 and October 1952 - February 1953, providing a base for both Marine Corps fighter-bombers and Navy anti-submarine planes, depending on the operational needs most critical at the time.

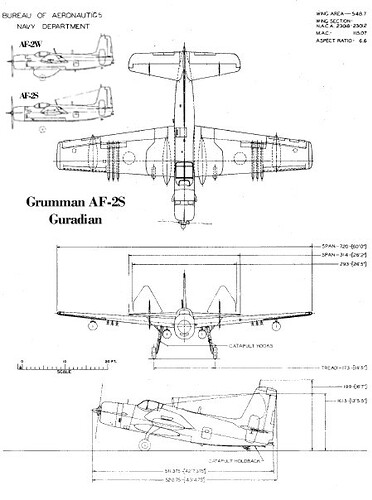

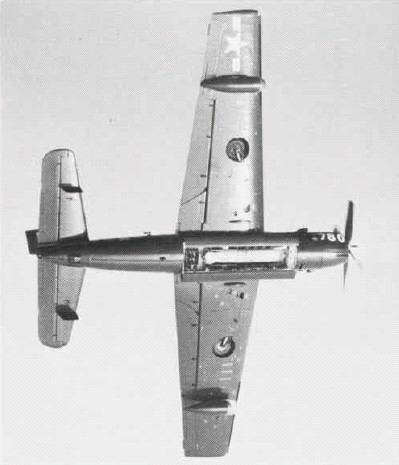

That’s a pretty small flight deck for the largest single-engine propeller aircraft ever operated by the Navy off of aircraft carriers!

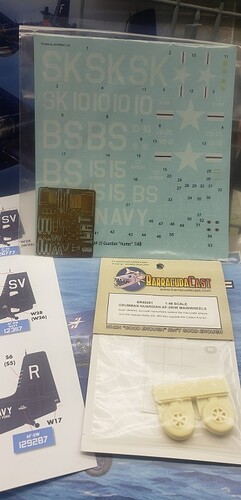

I’m using Caracal decals for my subject, which you can see in the middle.

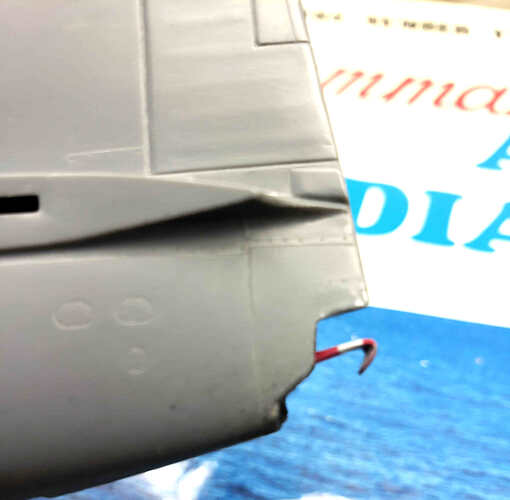

Aftermarket details will be minimal because there aren’t many! I am using Barracuda wheels with the correct number of spokes in the wheel hubs.

One big downside of these kits is that there are no aftermarket instrument panels and not even instrument decals sheets for them. Just the plastic bevels for the instruments.

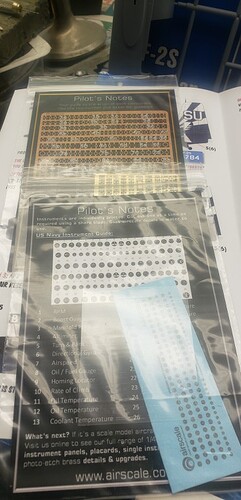

To address this, I’m going to have the fun of punching out the Airscale decals below, though I decided the brass bevels were overkill.

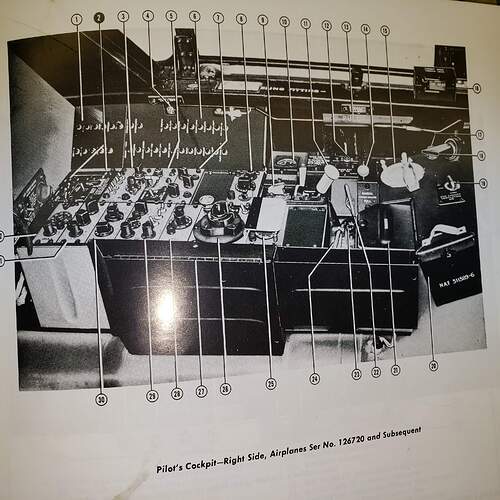

For the side panel instruments, I found a copy of a decal online for one version of this A/C (the “MAD Boom” SH issue, which SH didn’t bother to include in the earlier kits.) I downloaded it and printed it out, “adapting” it to the kit with “mixed results,” shall we say. In any event, it’s better than nothing, I think. ![]()

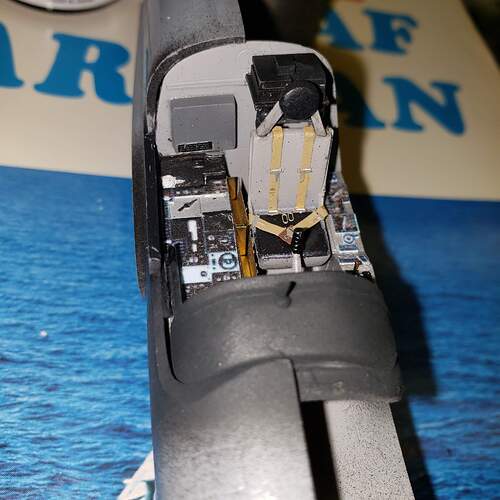

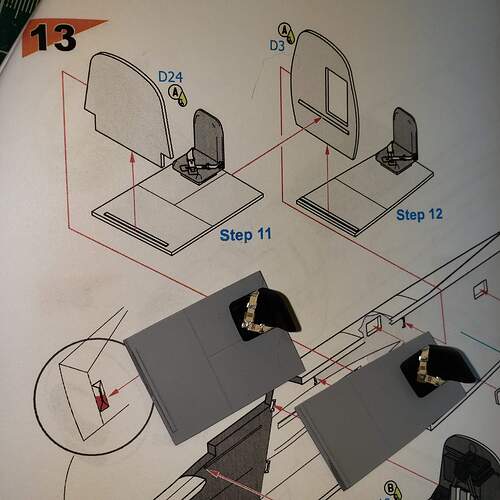

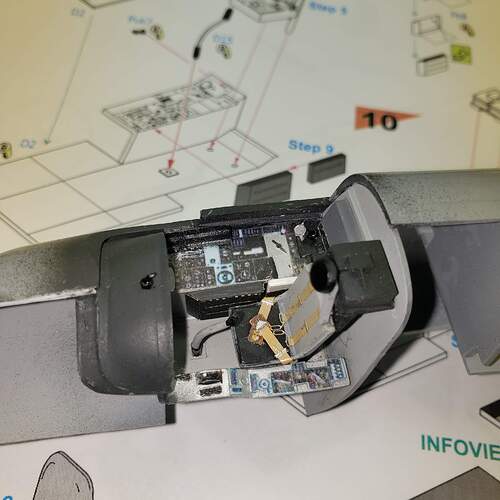

Here are three views of the just-completed cockpit.

Yes, there is some touch-up needed, and I will probably, carefully, paint the exposed brass of the interiors of the map/documents holders to the right of the pilot seat in the same color as their black exteriors. Only after I installed them did I see how visible they are.

I’ve done better cockpits but lemme tell ya, it was a chore just to get this done! This kit is my first Special Hobby build, and they are DEFINITELY “limited run” products. There was a lot of filing, sanding (and cursing) that accompanied this part of the build, and the instructions were less than helpful. They didn’t even cover installing the instrument panel!!

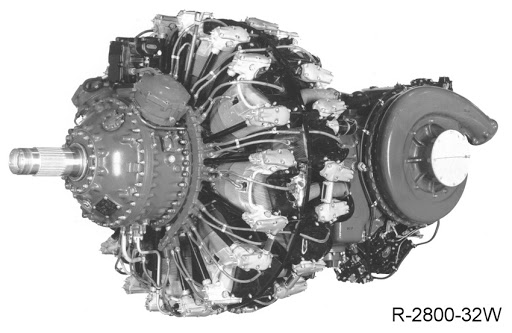

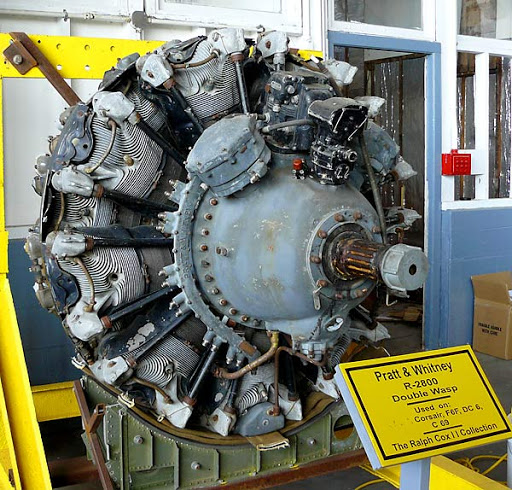

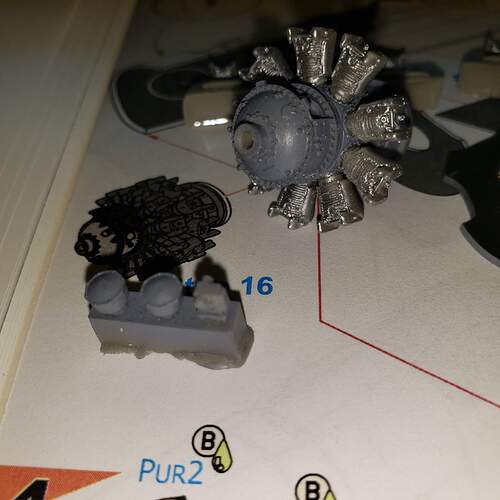

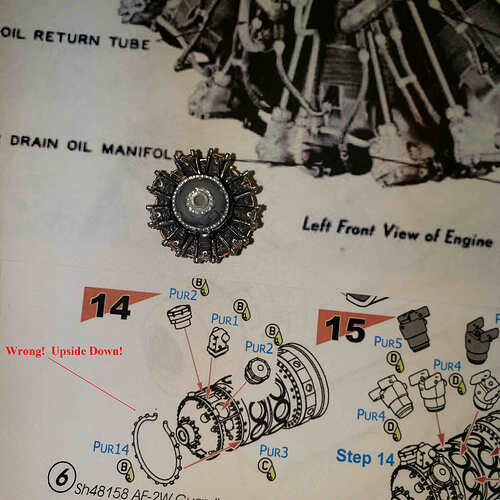

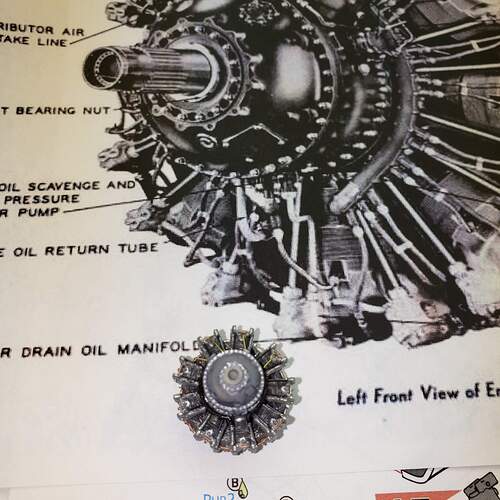

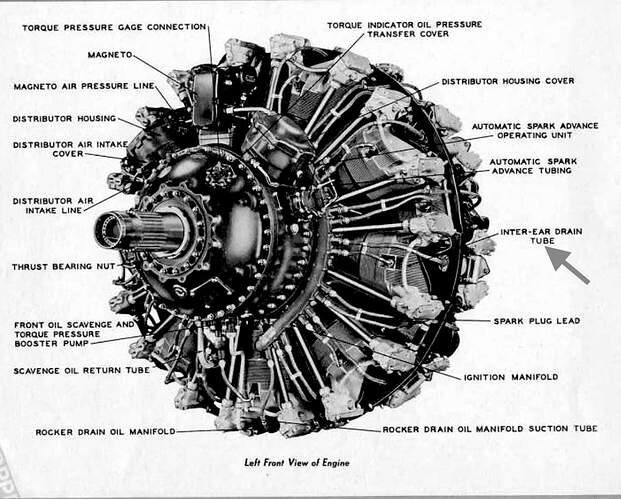

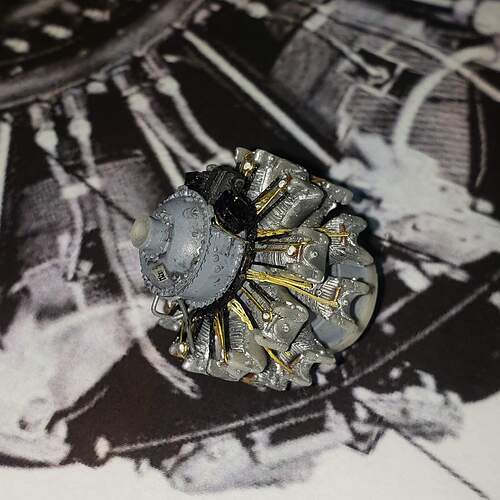

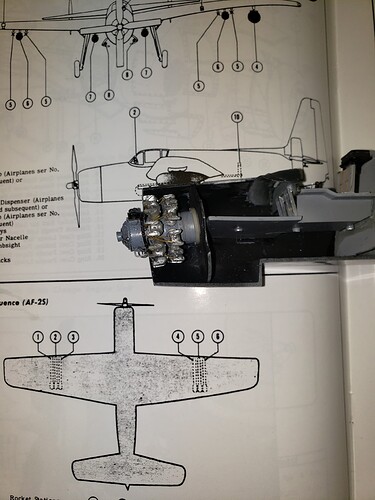

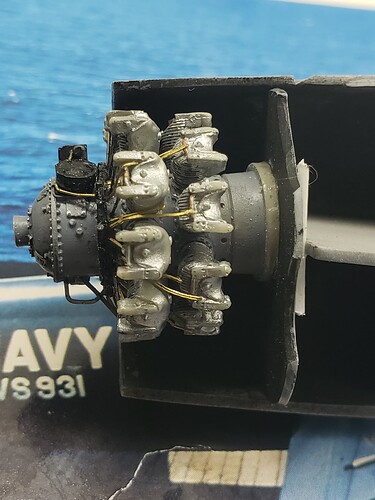

Next is the completion of two rudimentary crew spaces aft, which are barely visible behind small rectangular windows, and installation of a rudimentary firewall, which the instructions do not tell you must be installed at a slight, right angle, since the engine was offset to compensate for the strong torque generated by the aircraft’s Pratt & Whitney R-2800-48W “Double Wasp” radial engine, rated at 2,400 hp.

Stay tuned.