Hello everybody,

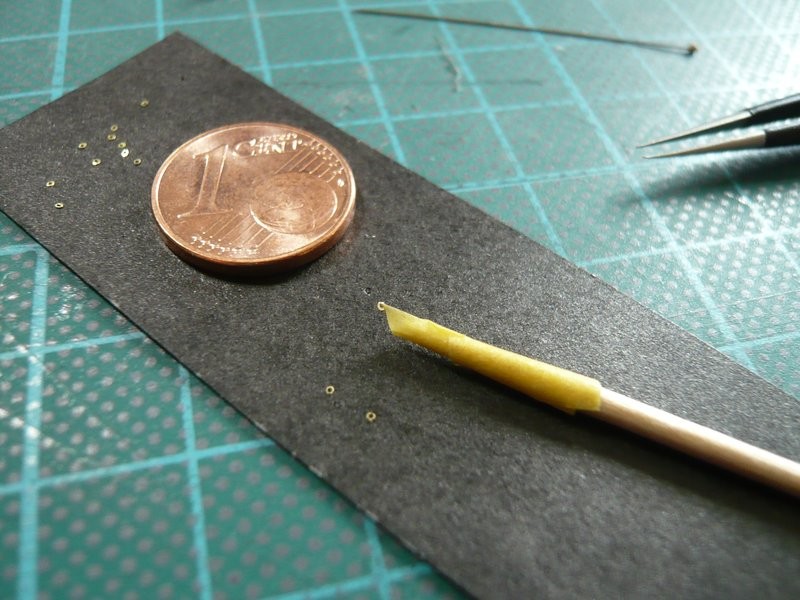

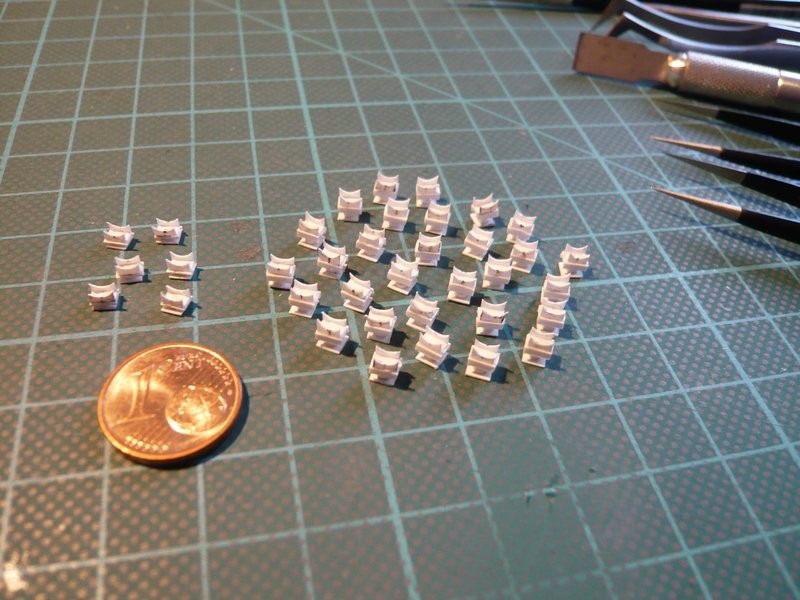

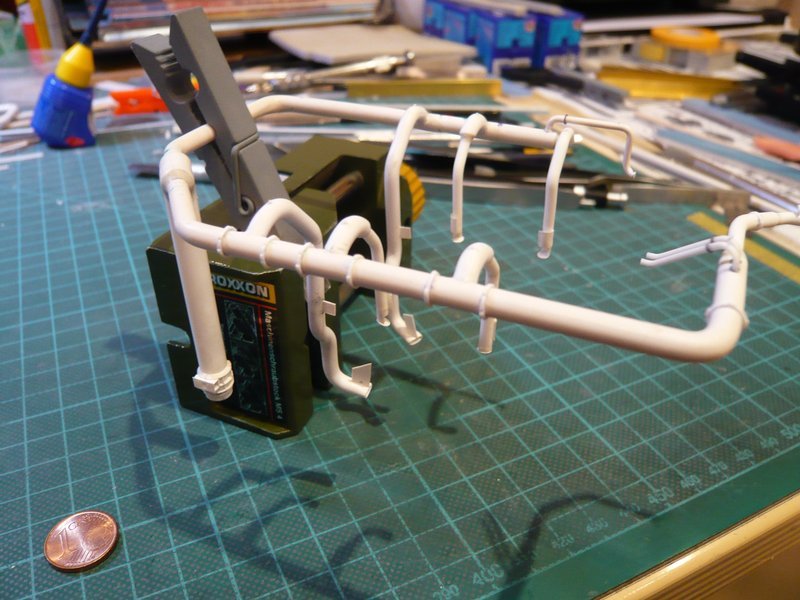

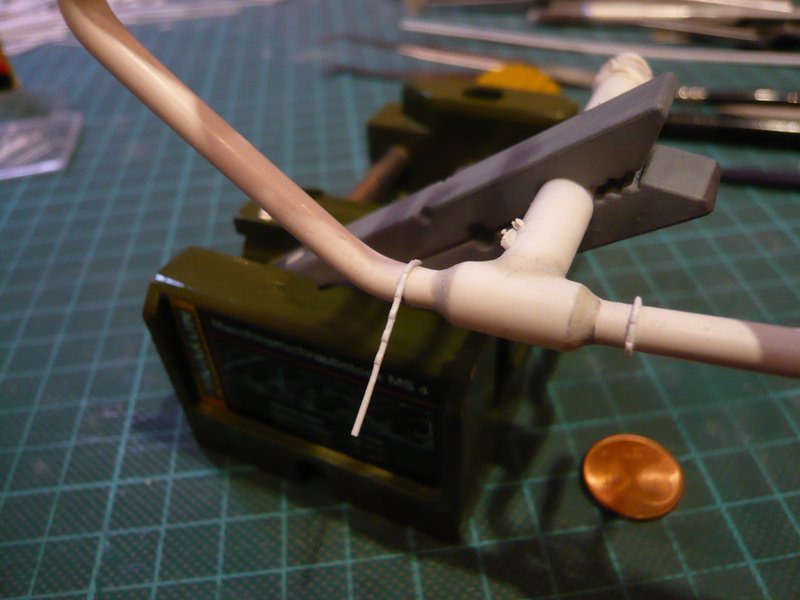

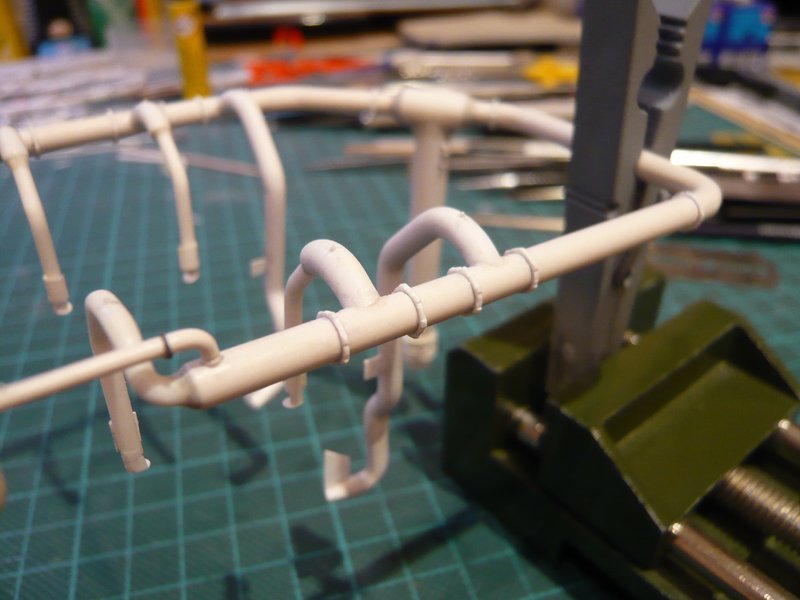

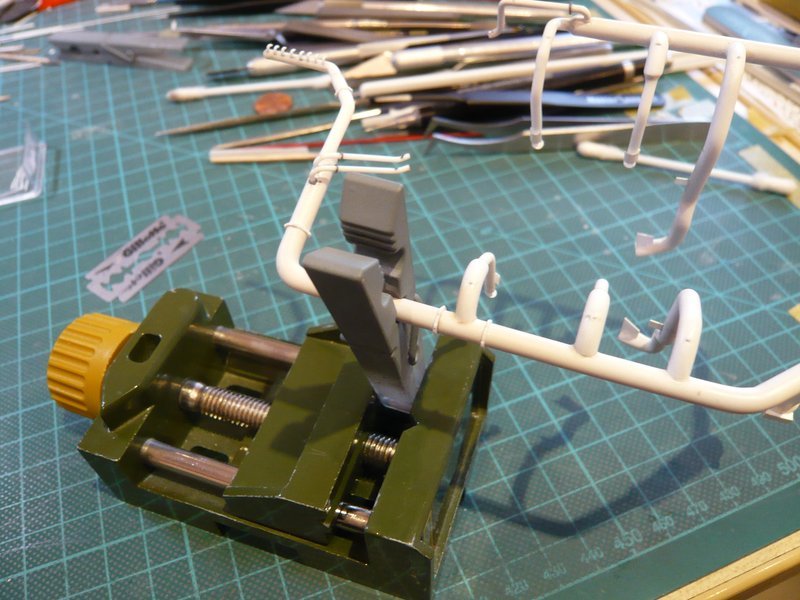

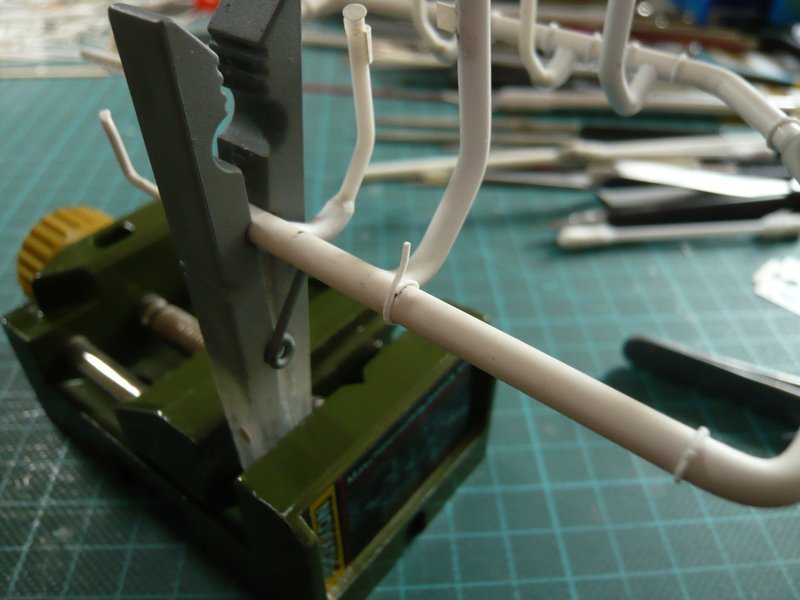

now for the gluing of the first clamping rings on the ring line behind the LH2-TSM, which has proved to be the expected tricky affair to do. ![]()

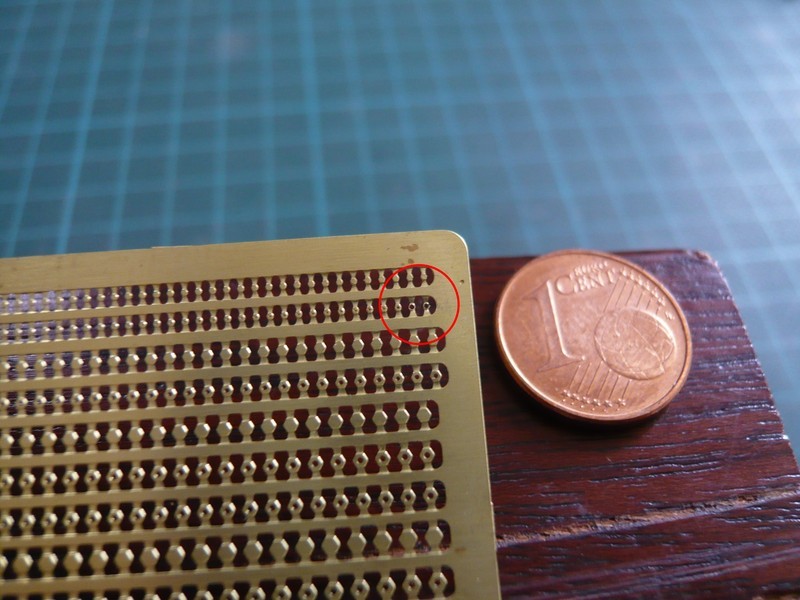

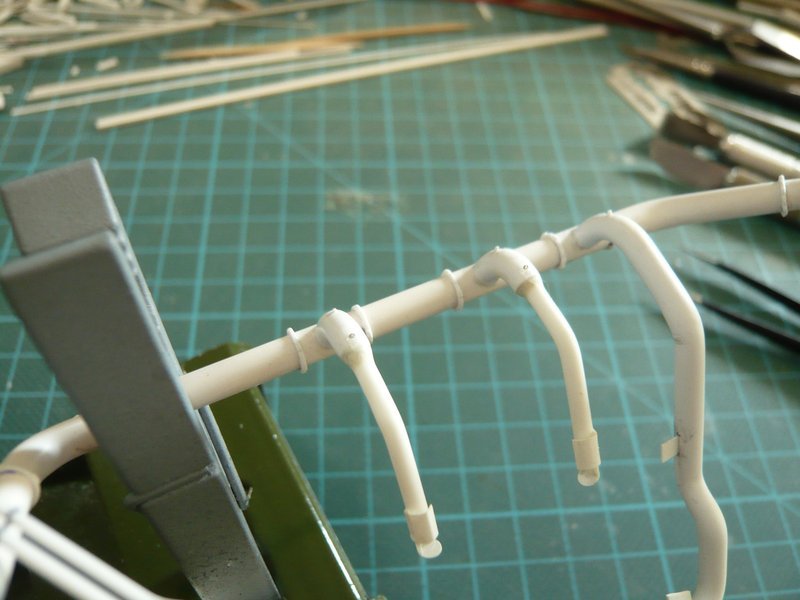

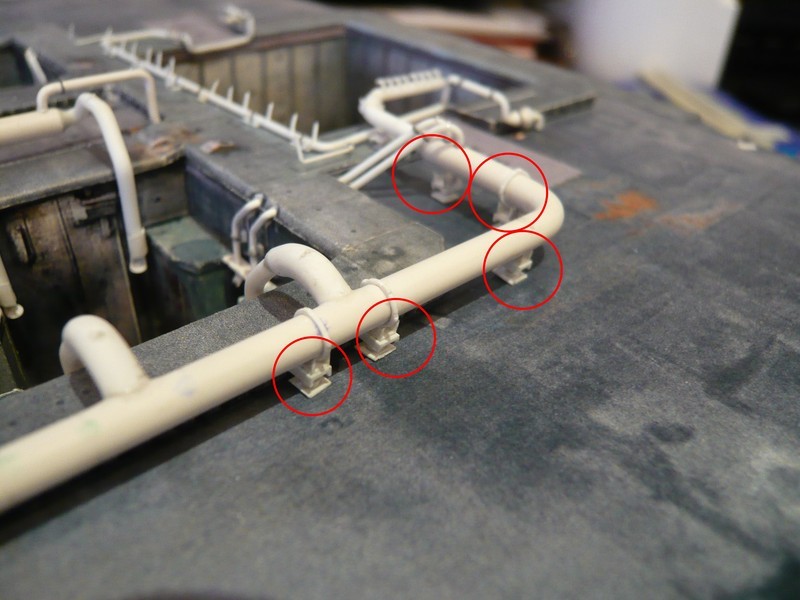

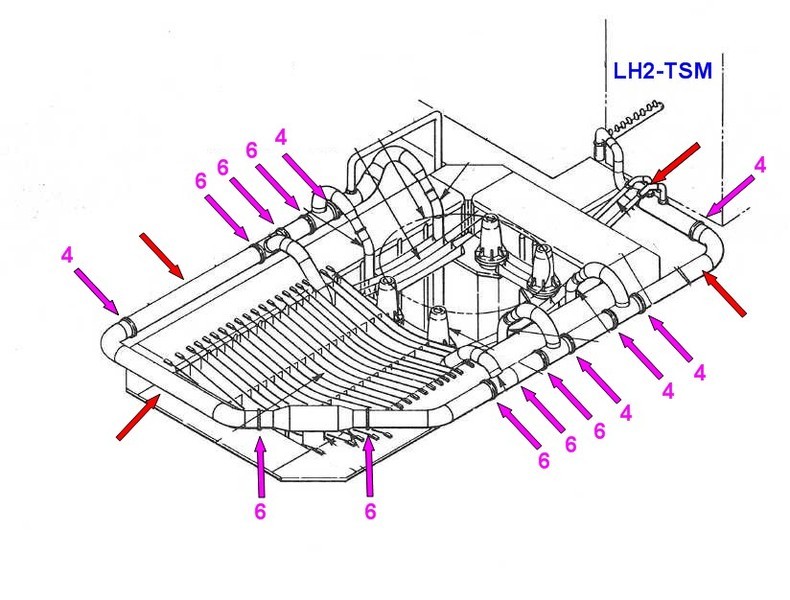

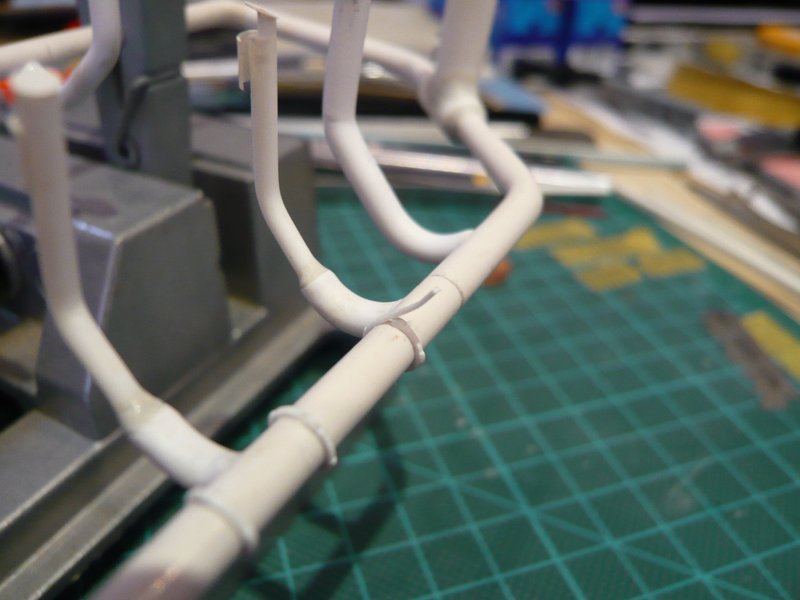

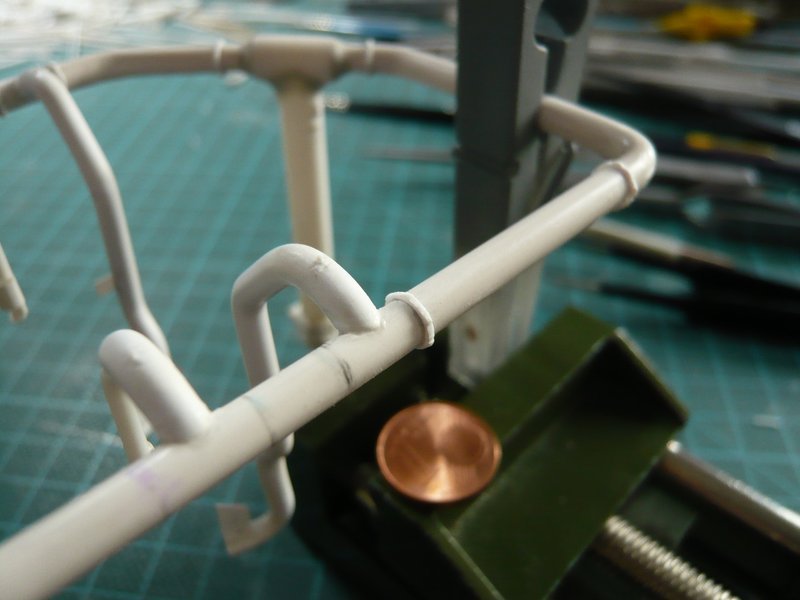

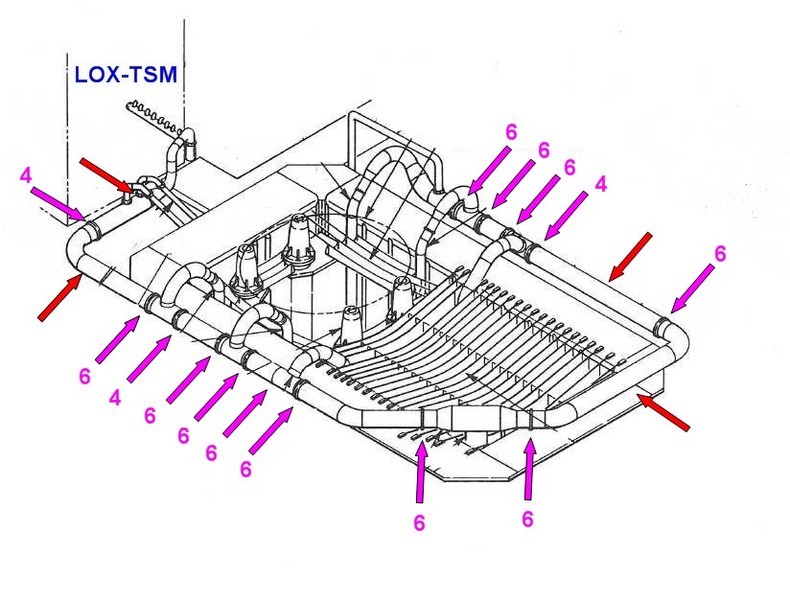

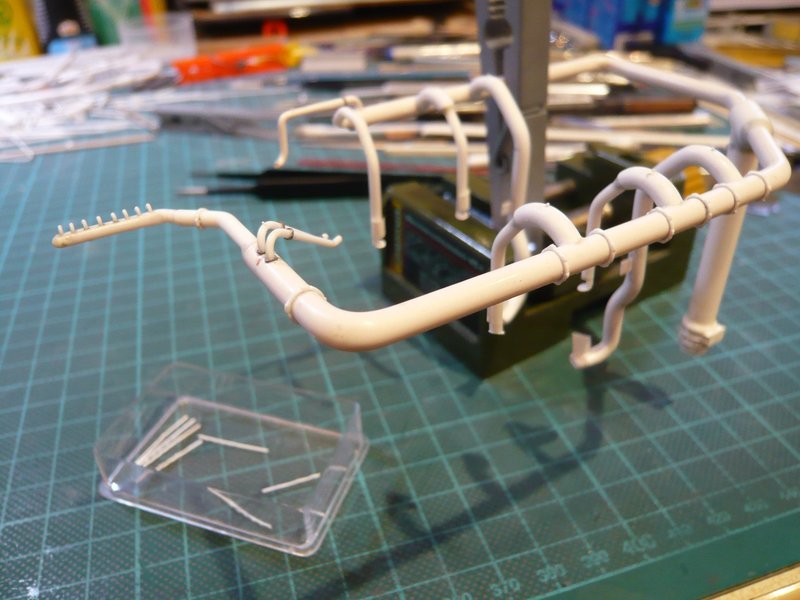

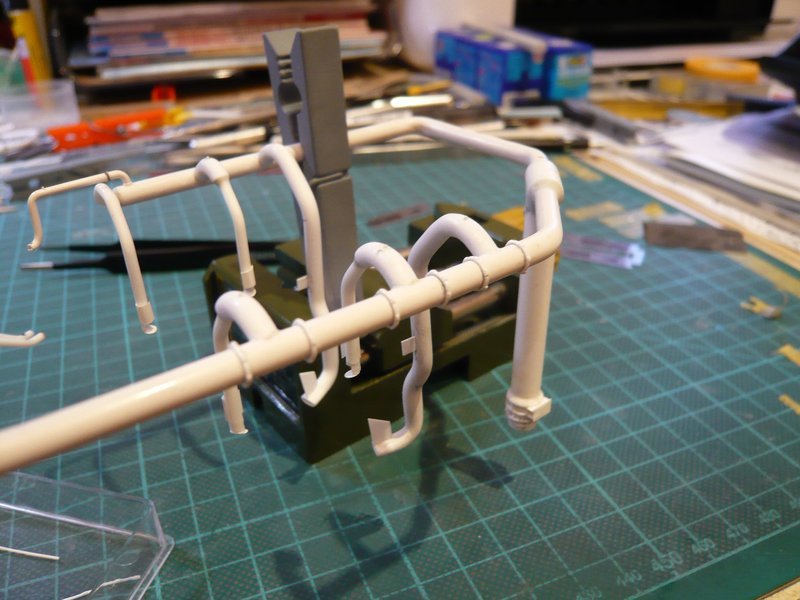

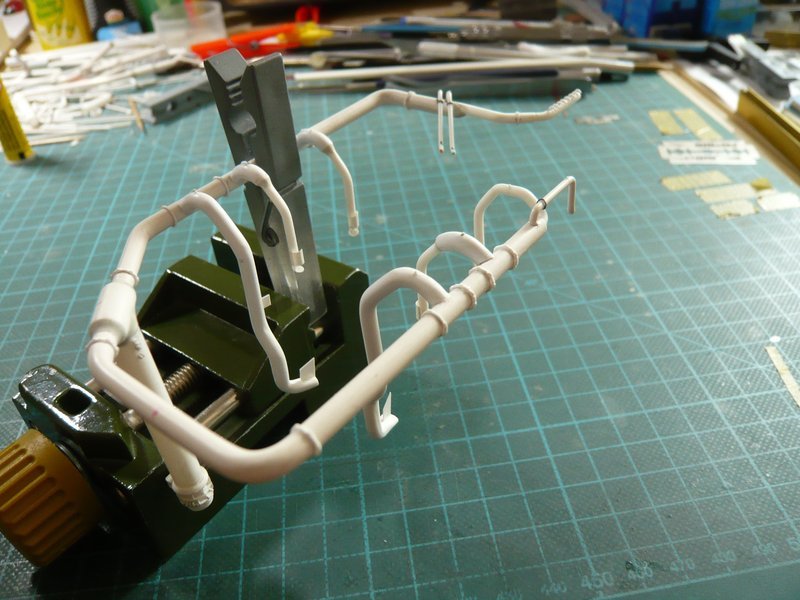

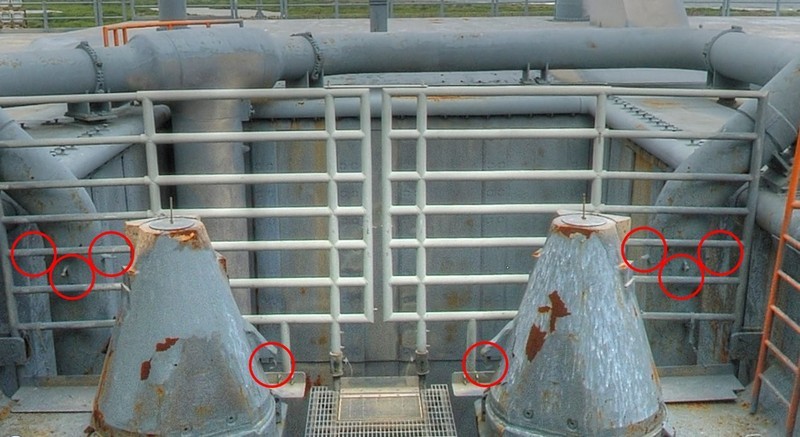

As can be seen in the picture, it started with four four-part clamping rings behind the TSM first, followed by five six-part rings. ![]()

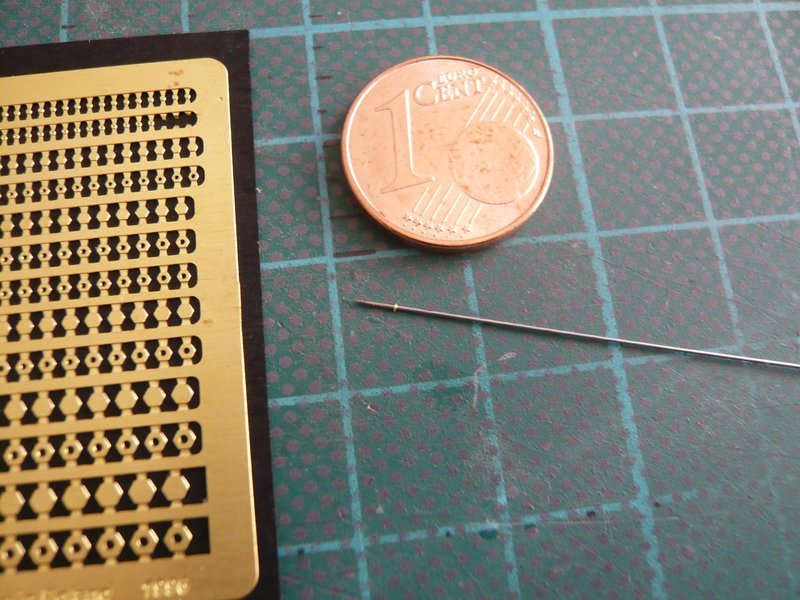

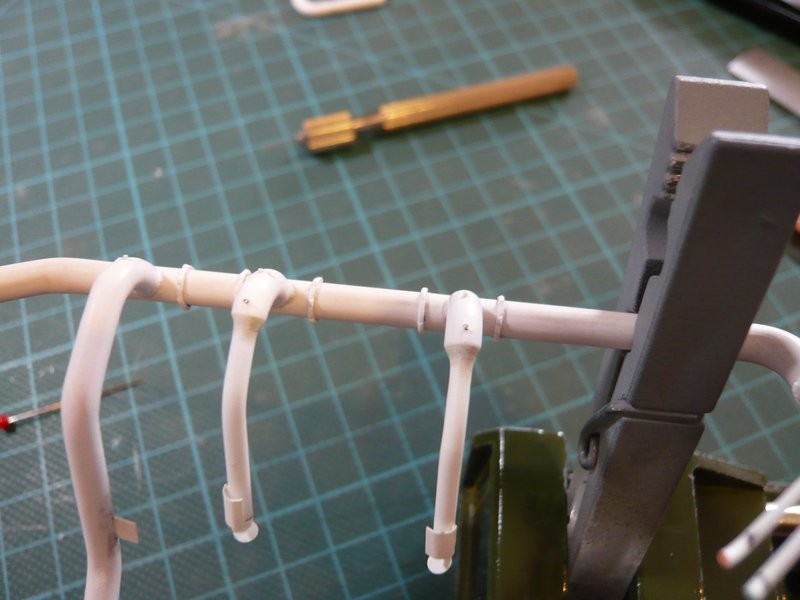

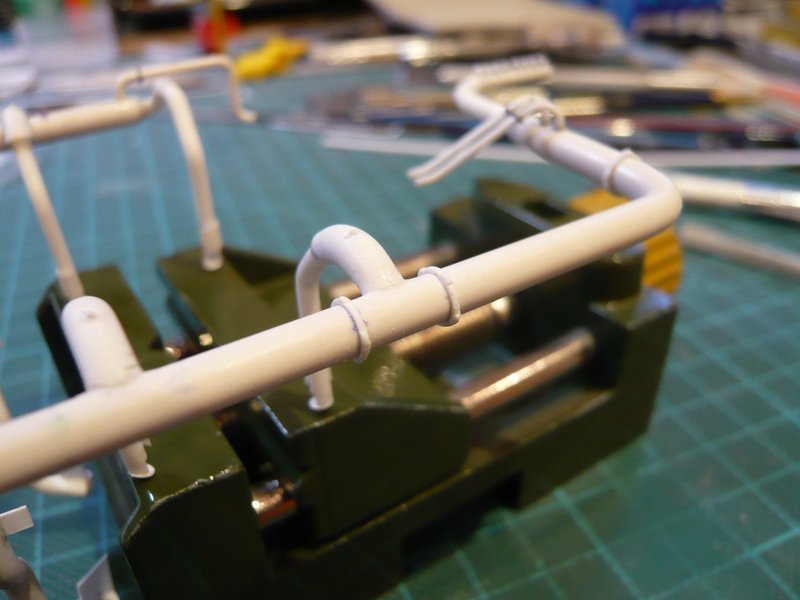

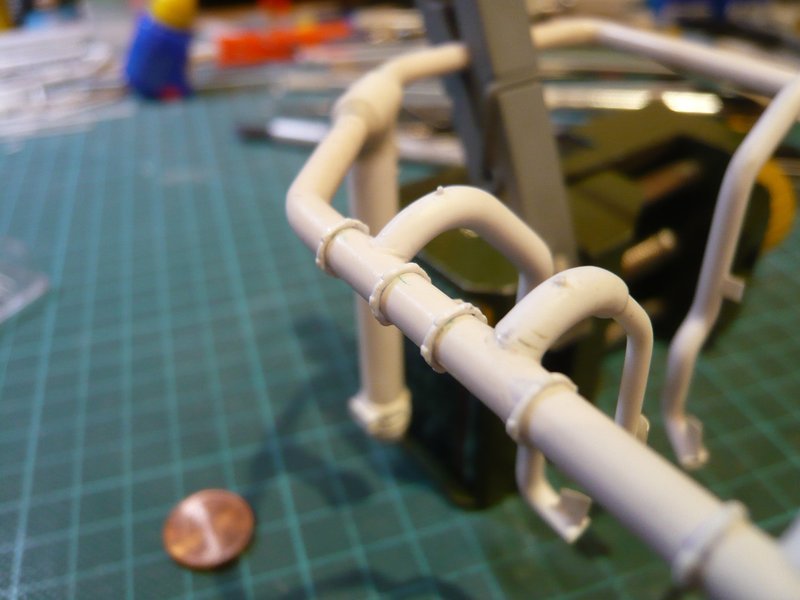

At that I proceeded during gluing in such a way that I first glue only the first screw connection on the underside of the ring line with CA, and the remaining ring then stepwise until shortly in front of the last screw connection, where the end of the strip is glued fitting exactly connecting with the first screw connection after cutting off the overhang.

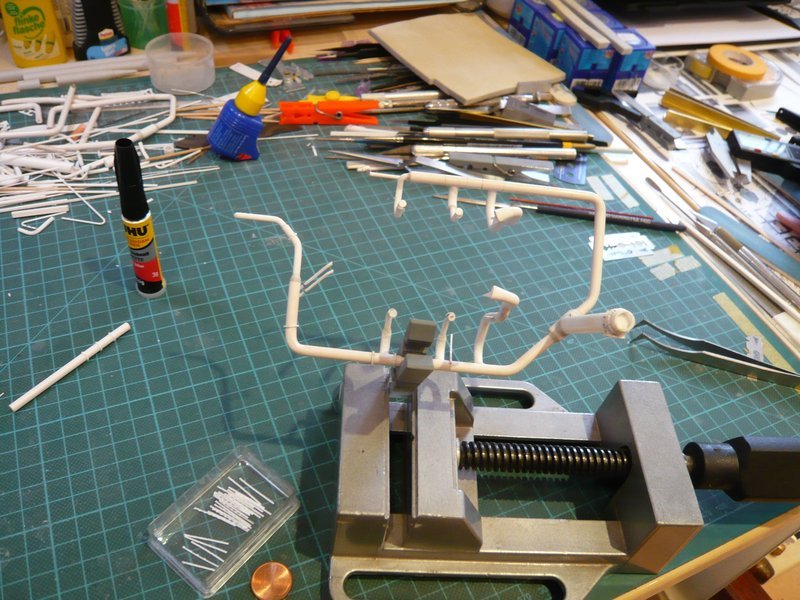

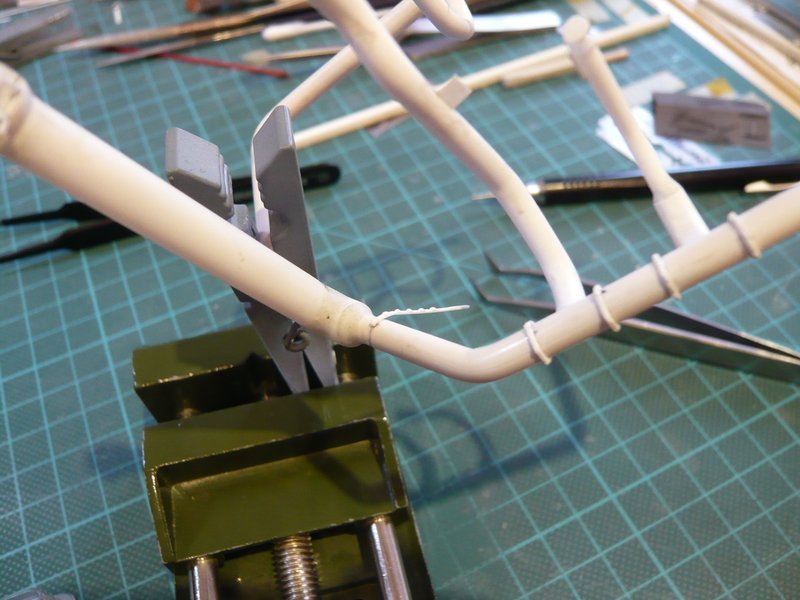

In order to allow the ring to be attached better when gluing, it is advantageous if the starting point behind the first screw connection is carefully pre-rounded. But already the start was a complete flop, because the first screw connection was broken off, which has surprised and frustrated me of course. ![]()

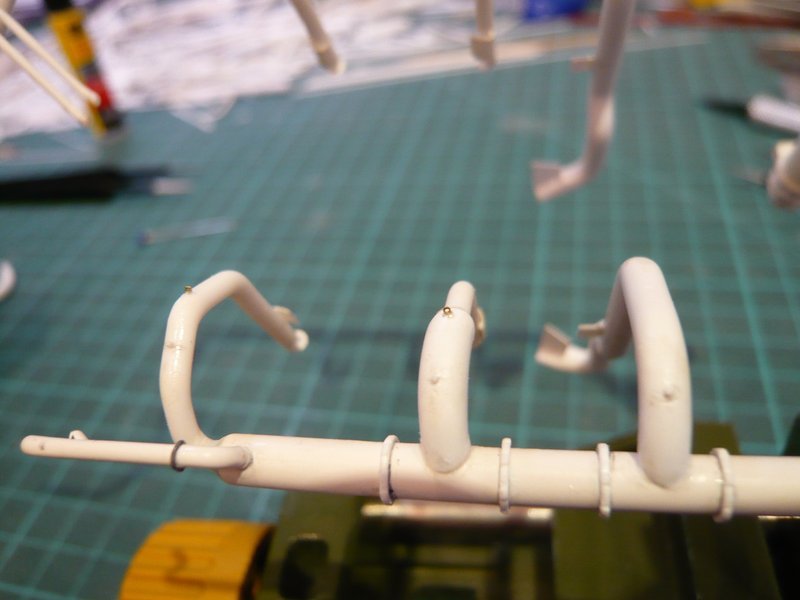

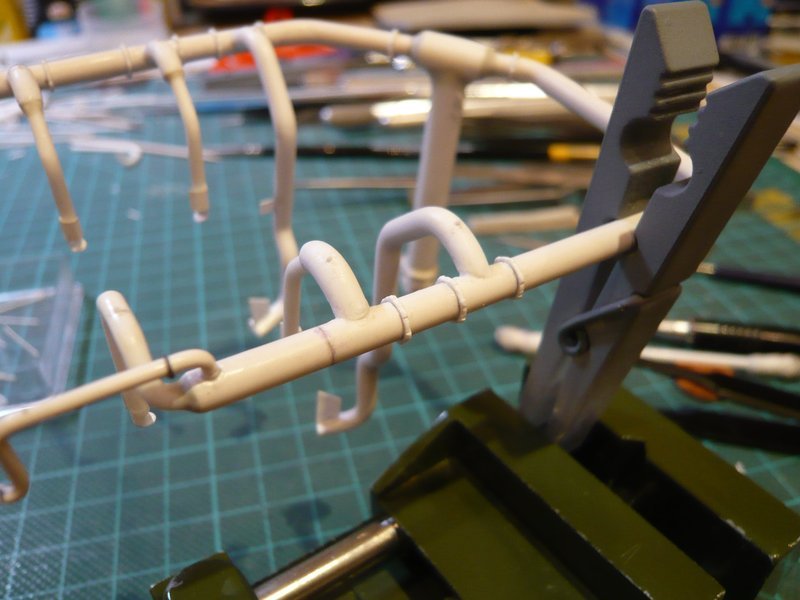

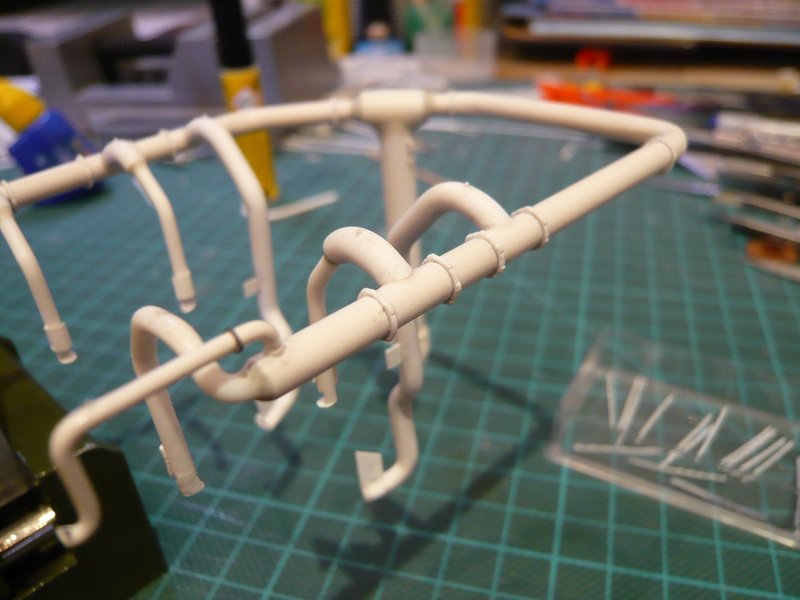

I can only explain it to myself, that the strip has been scratched too much during the chamfering of the screw connections and thus unfortunately had a predetermined breaking point. ![]()

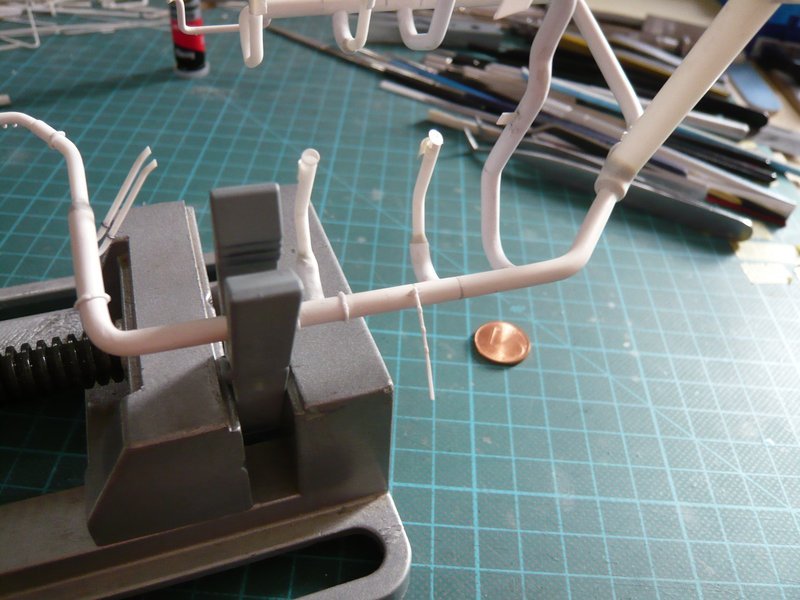

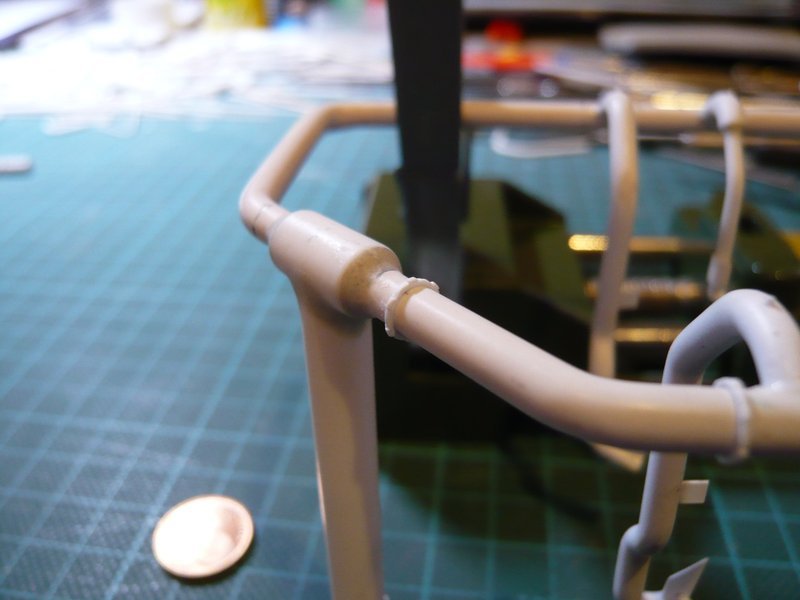

This can happen already, but should not throw me off track, which is why I then went on still more cautiously. ![]()

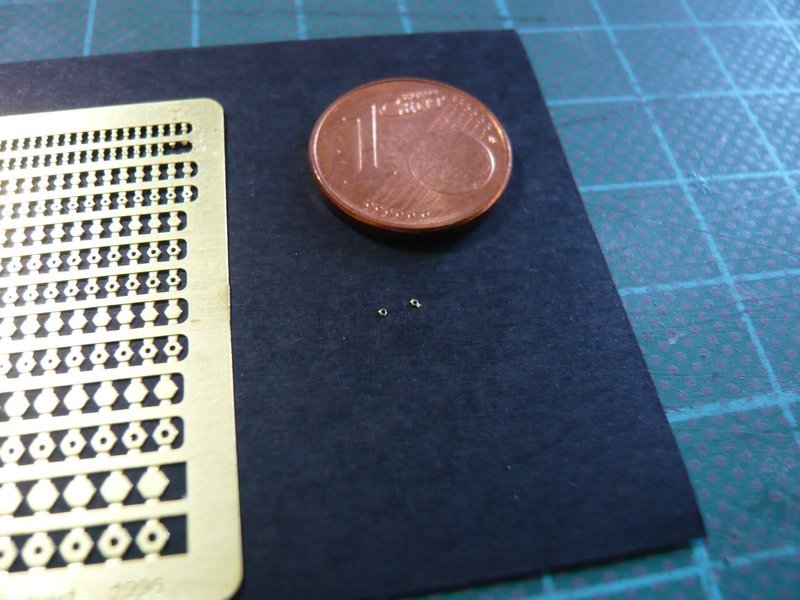

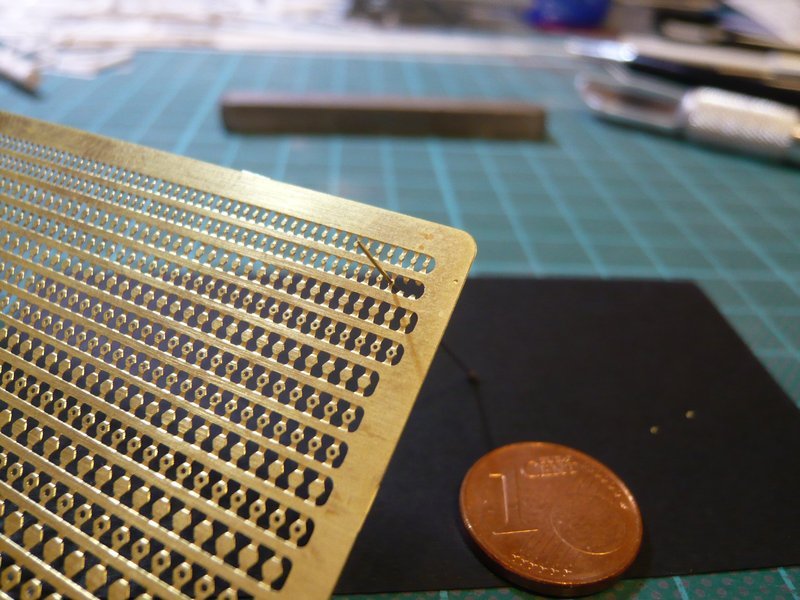

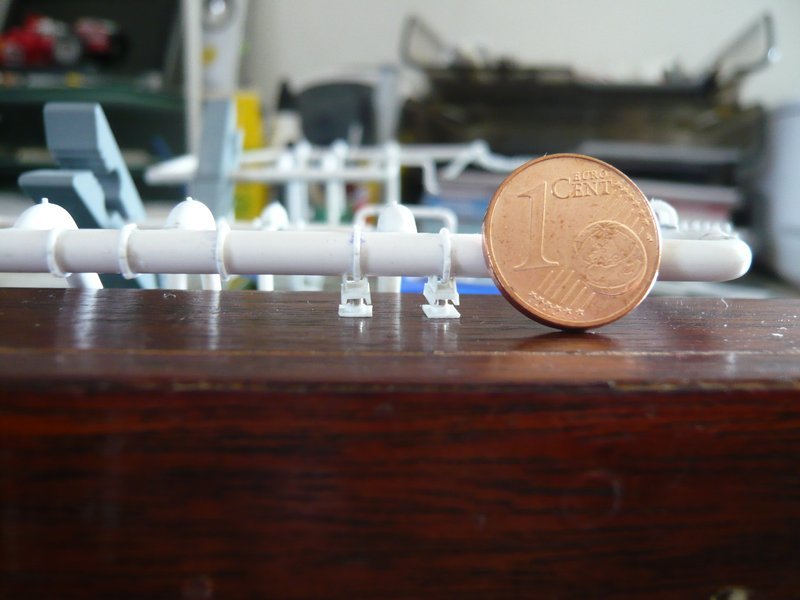

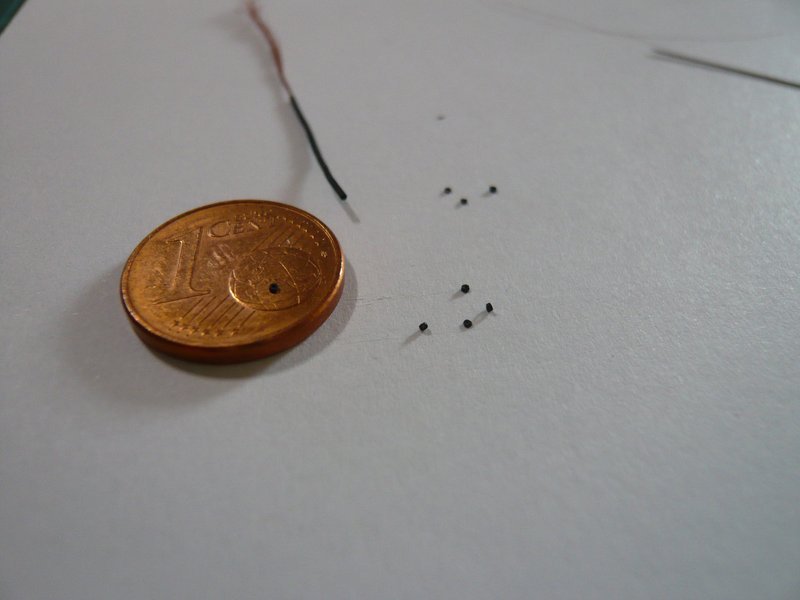

So I have glued the barely 1 mm long tiny screw connection and behind it then the remaining clamping ring, which still looks quite neat. ![]()

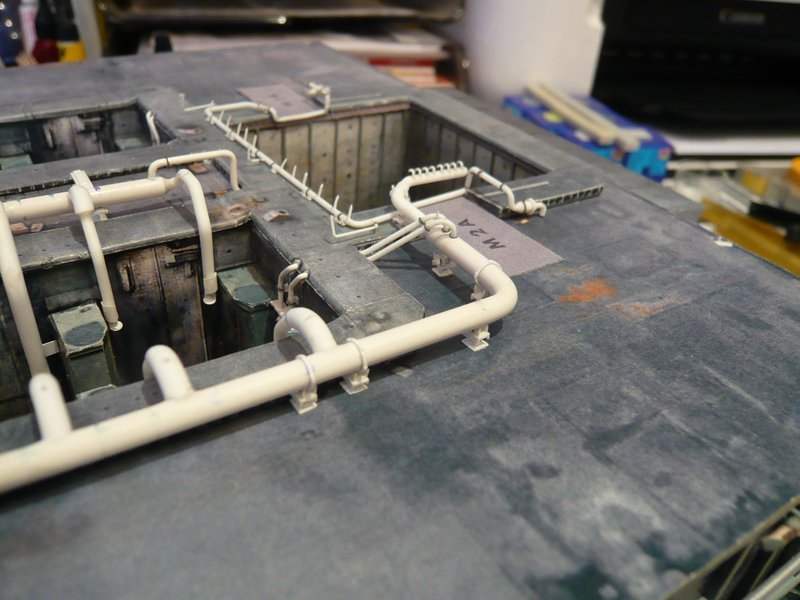

And in the same way followed the next two clamping rings, but unfortunately again not without slip-up. ![]()

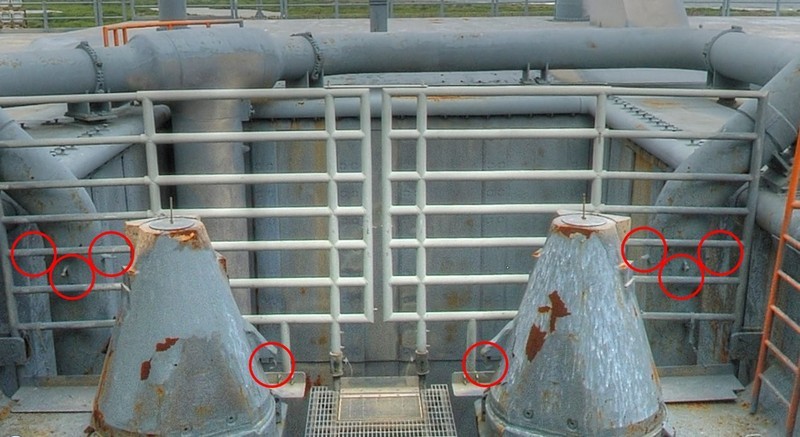

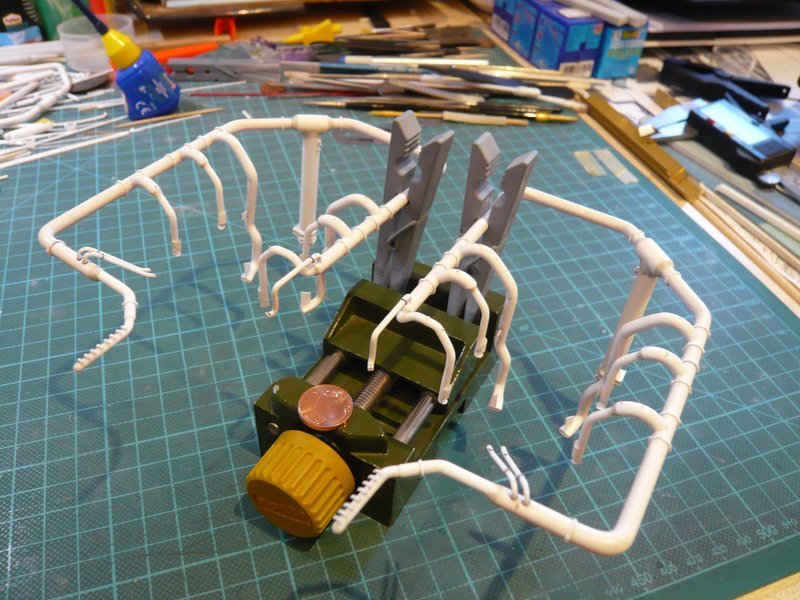

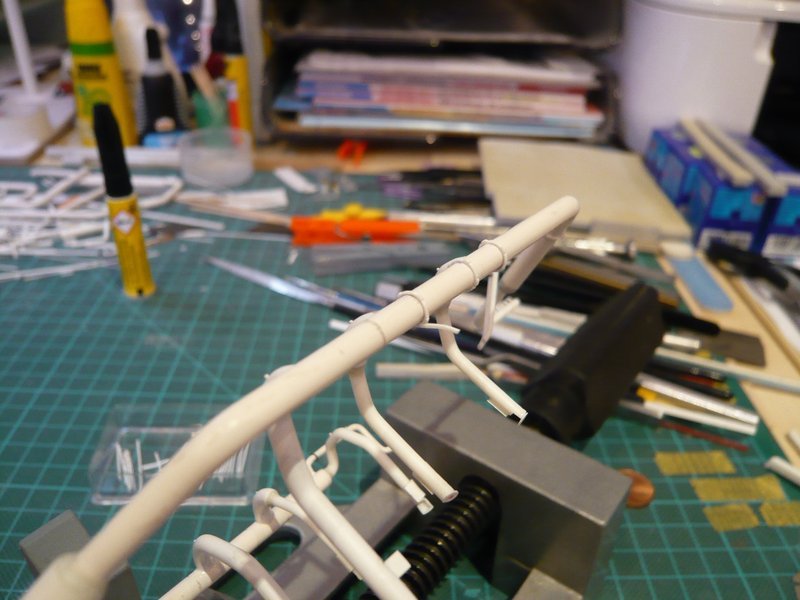

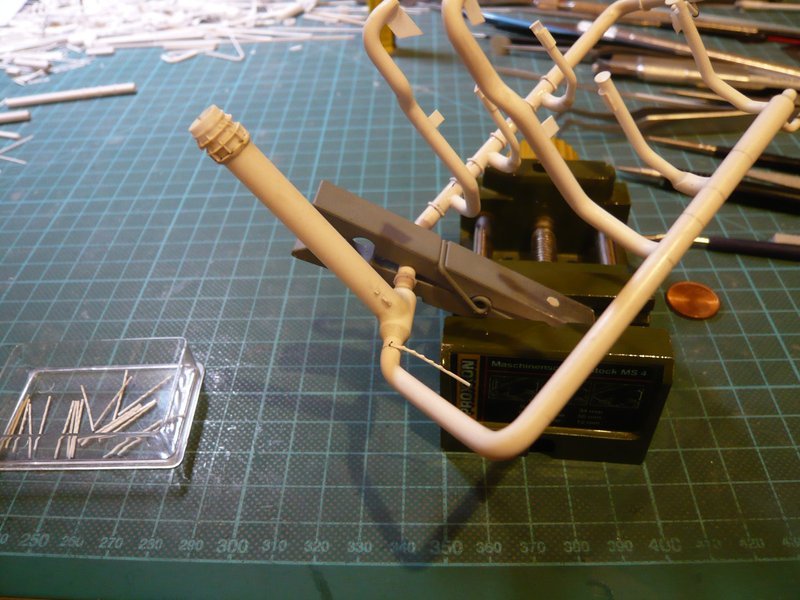

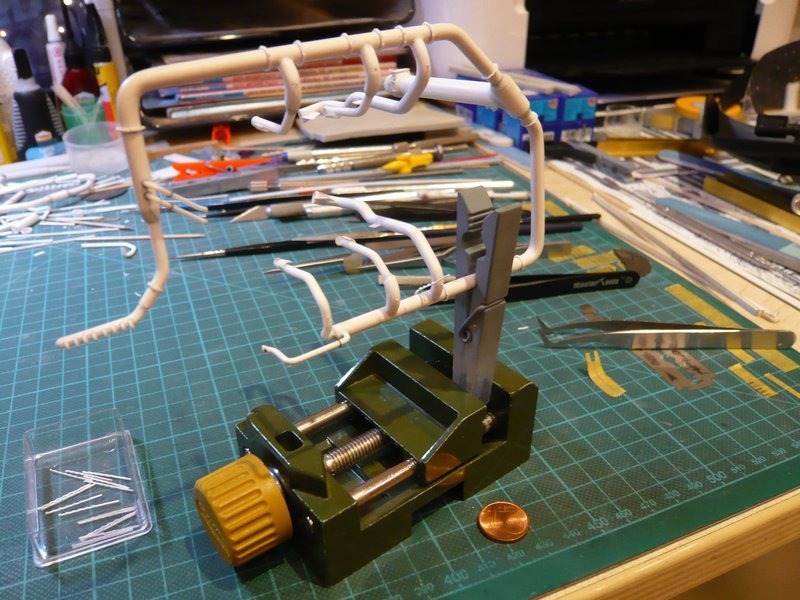

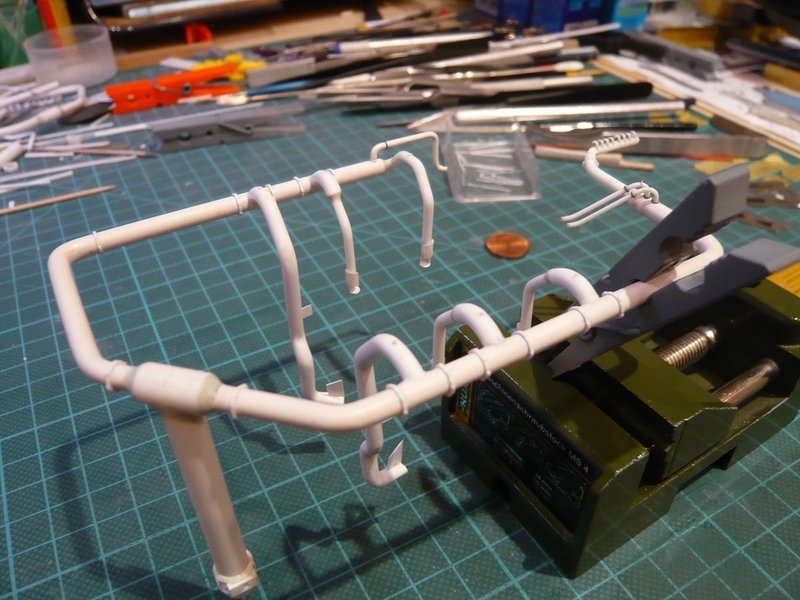

Because as I had already emphasized, one must clamp the ring line somehow, so that one has free hand, in order to position the clamping ring exactly and to press it smoothly.

I had the ring line in my little vise already, but the inner 18’’ outlet layed obliquely at the vise, and during the careful pressure of the clamping ring there was suddenly a quiet click, at which I already suspected something bad … ![]()

And after clamping out of the ring line I got prompt the receipt, because the outlet had done its name all honor, and had gone out off the ring line, by which I was badly served and needed fresh air. ![]()

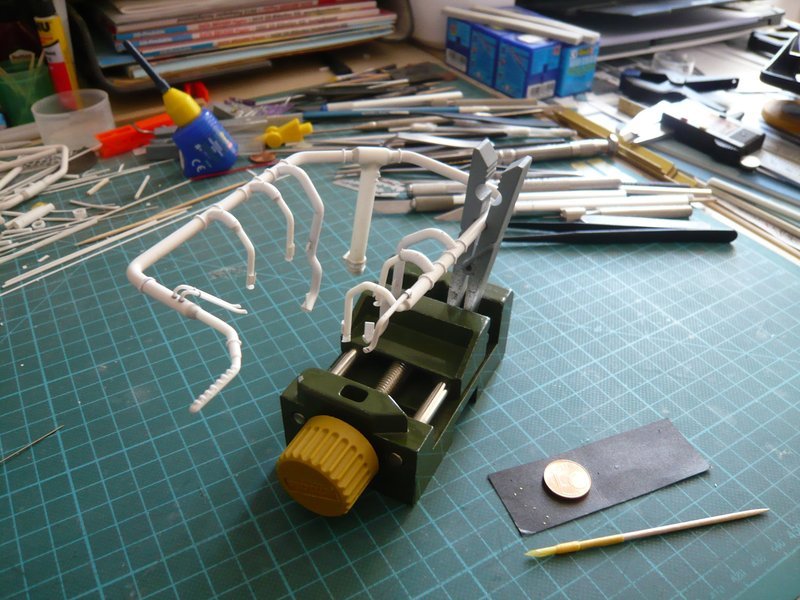

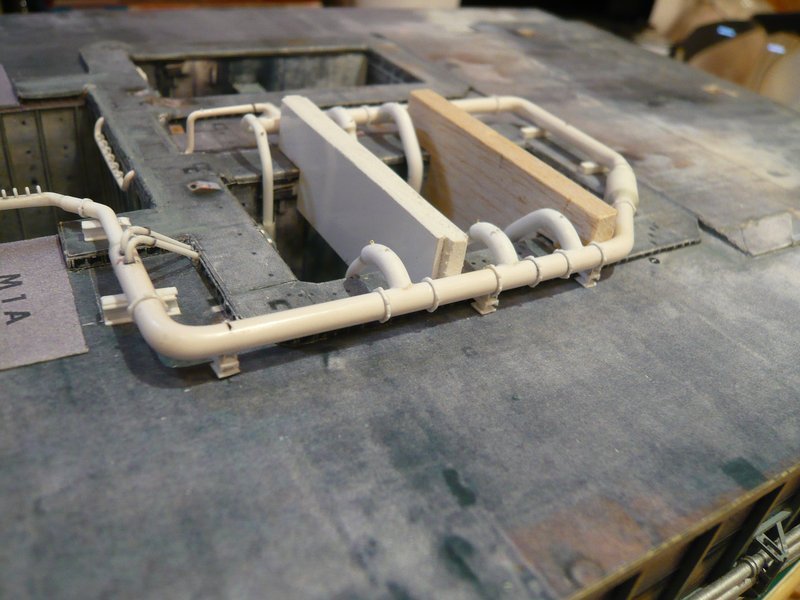

Afterwards, I have the ring line again in the SRB chamber inserted and the outlet again glued on. And this gave the opportunity to try out the supports just under the first clamping rings.

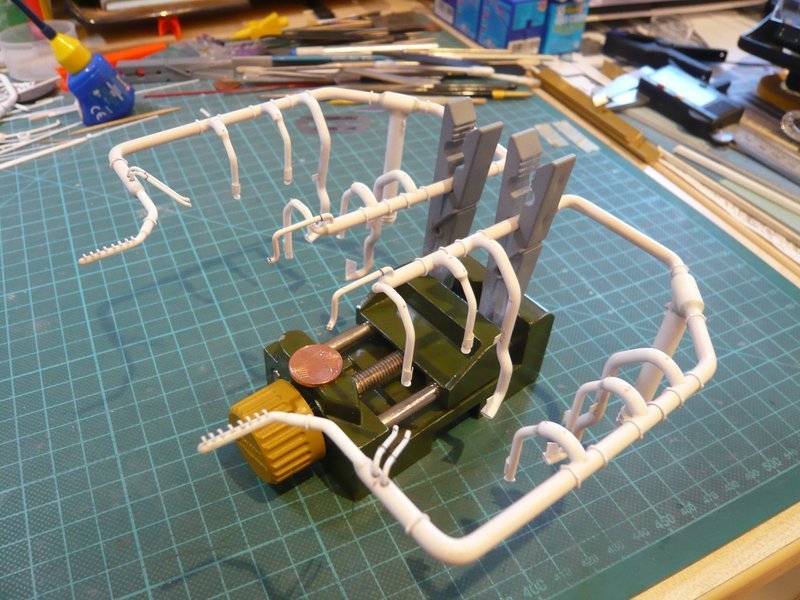

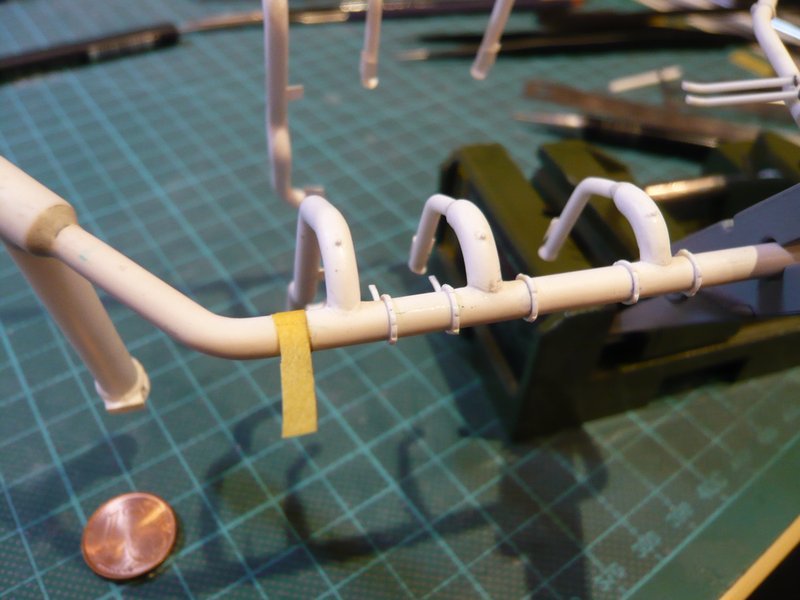

Now I just hope that the next clamping rings do not create similar difficulties and are good. ![]()

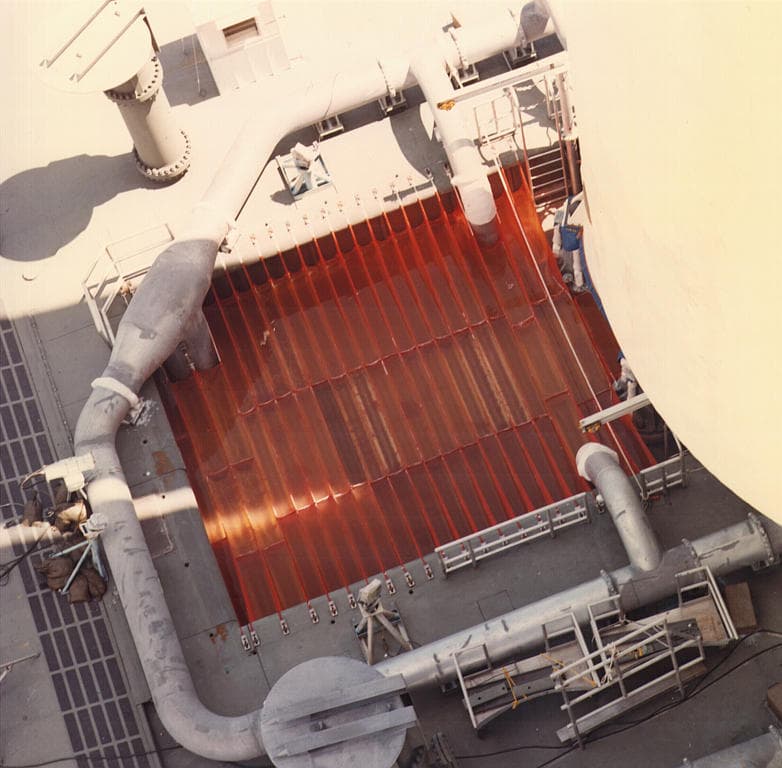

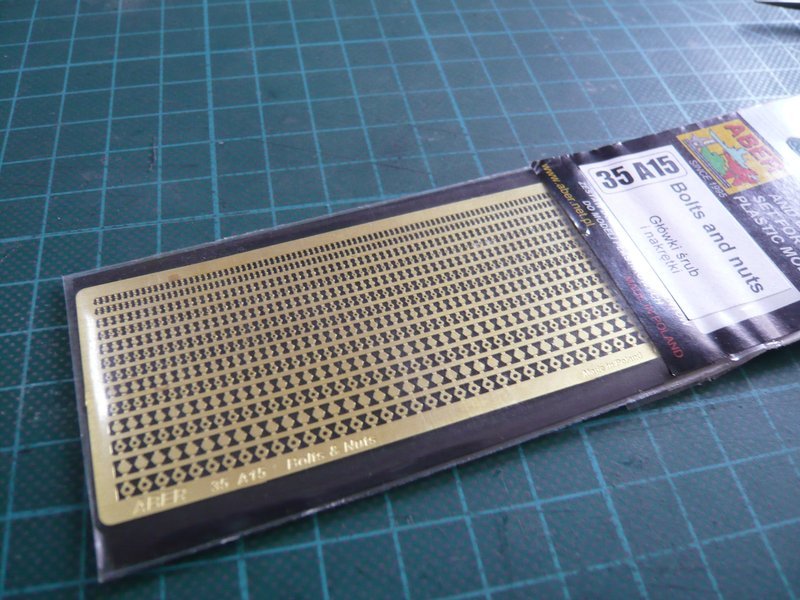

![]()

and I felt me like in the wrong movie.

and I felt me like in the wrong movie.

which however are so tiny that one can hardly see them in the last two rows.

which however are so tiny that one can hardly see them in the last two rows.