Hello everybody,

Now I’m strengthened for a while,

and it can go on.

To the warm-up I have first done some small things, which I have put so far aside again and again.

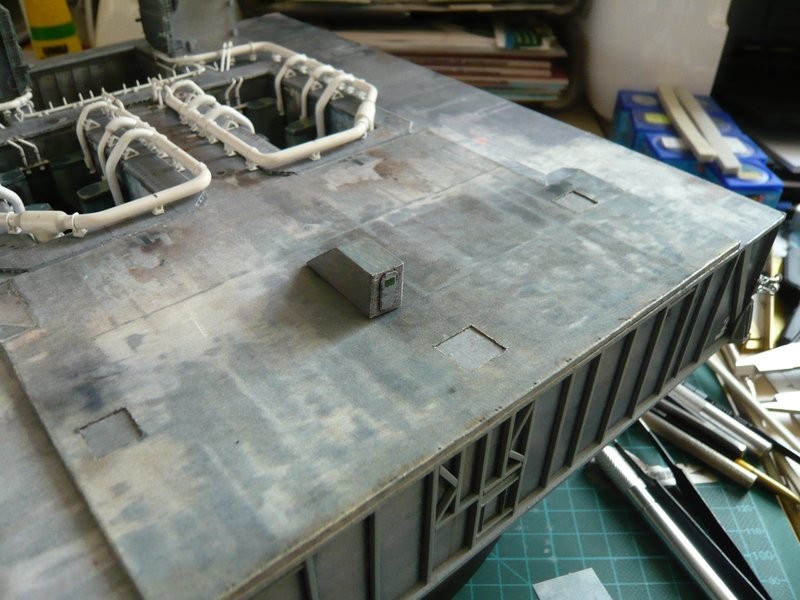

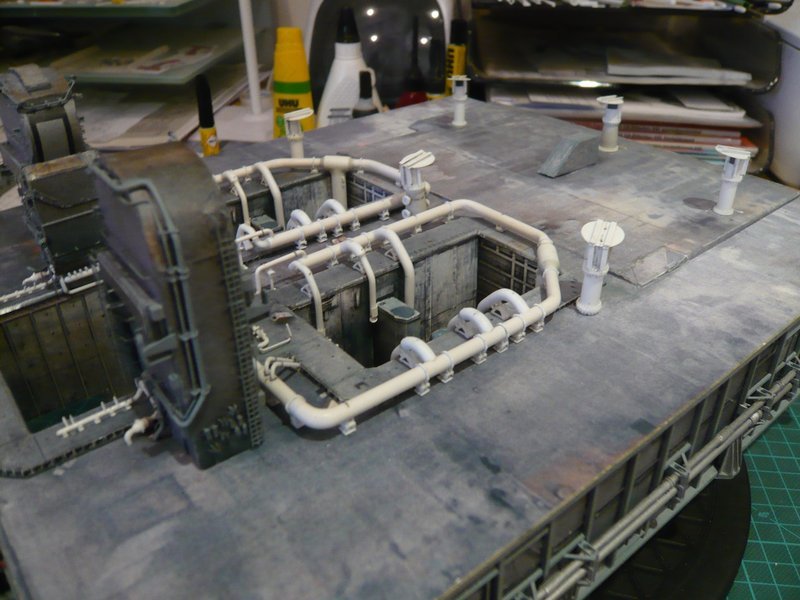

There were initially still to do the openings for the Rainbirds, what were now finally made. Since the openings in the paper kit were somewhat too small, they had to be corrected anyway. In addition, I had deepened them too far already, since they should only be about 0,5 mm deep.

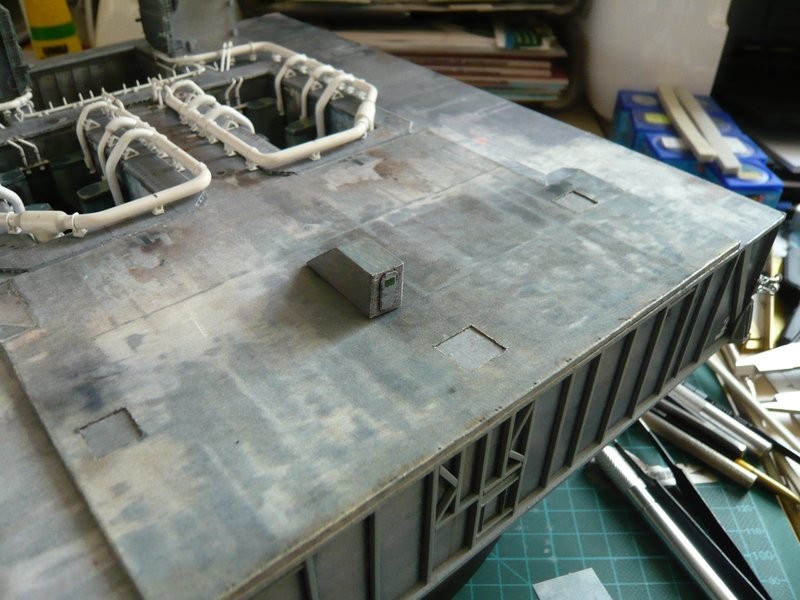

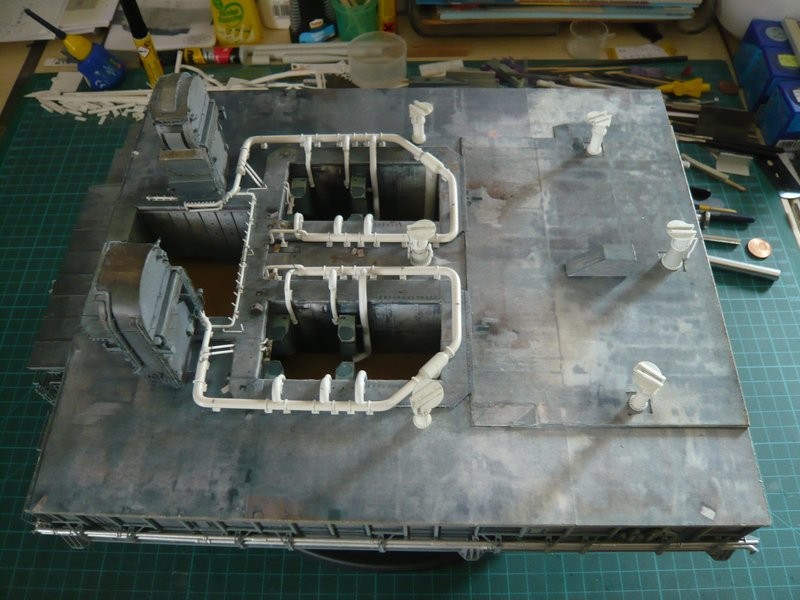

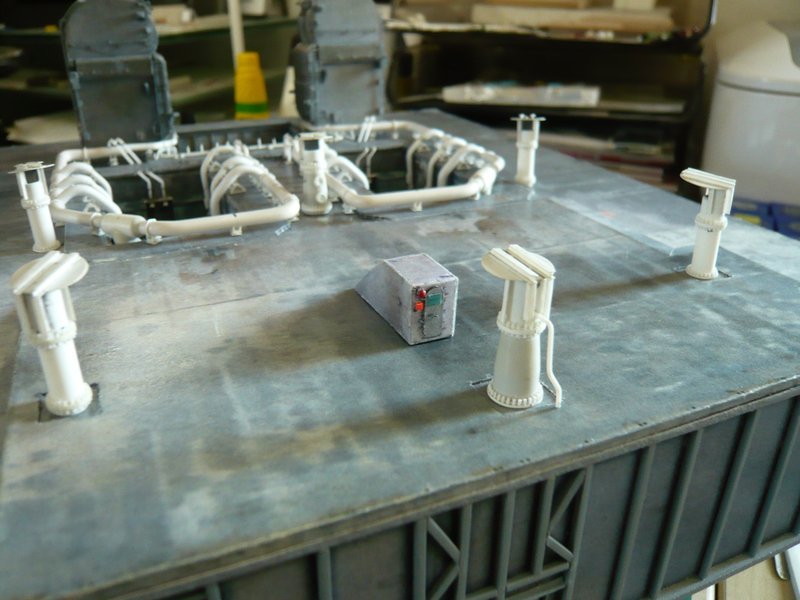

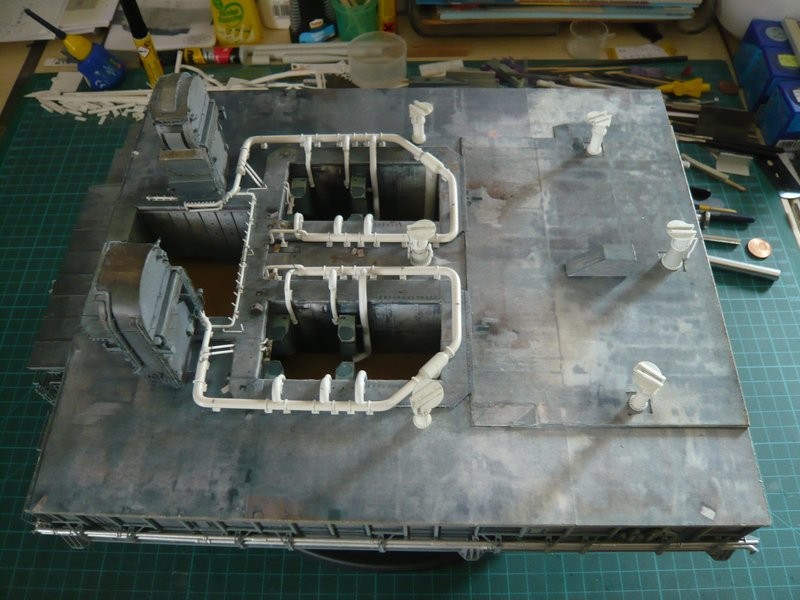

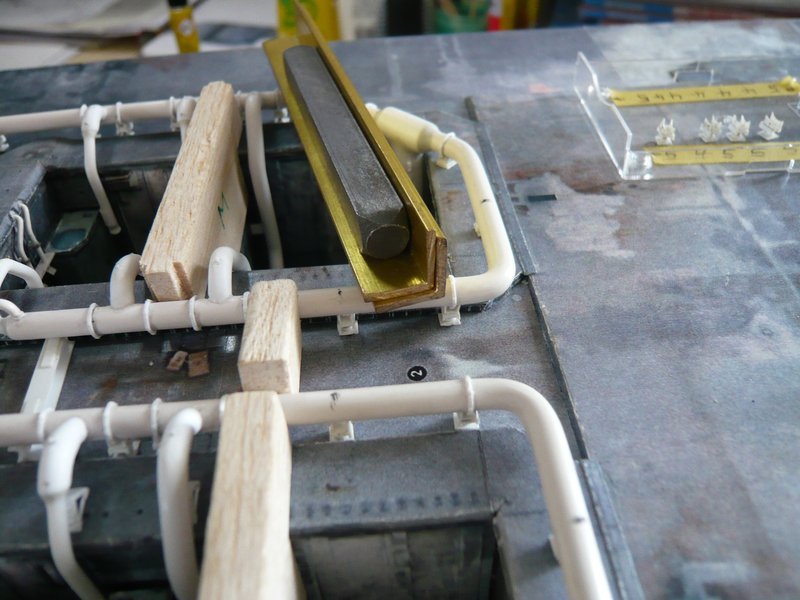

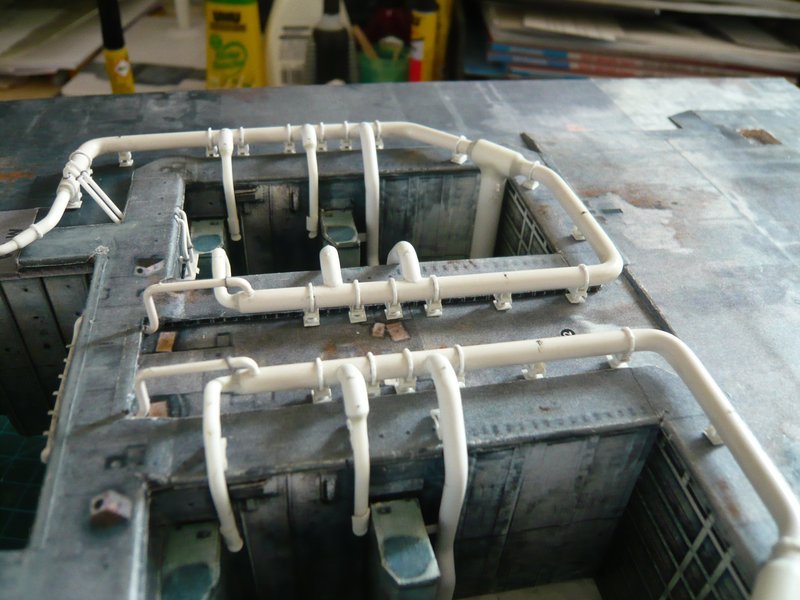

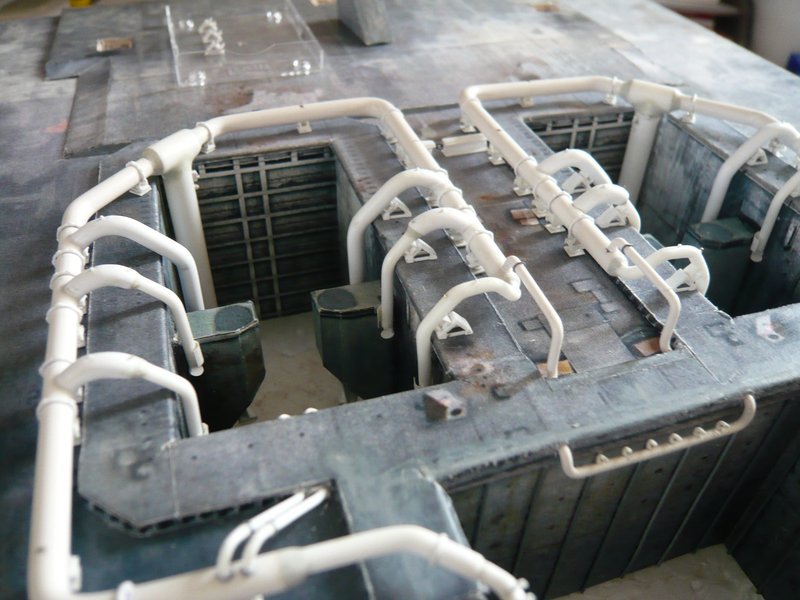

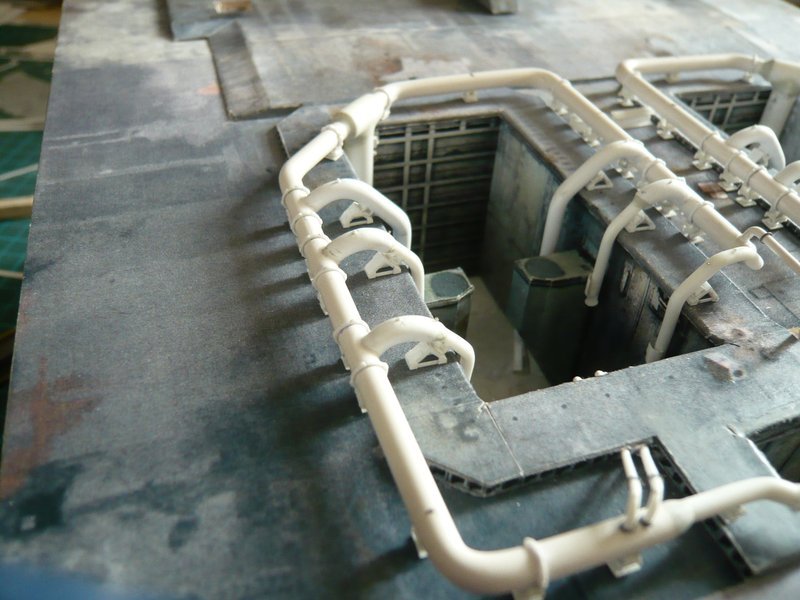

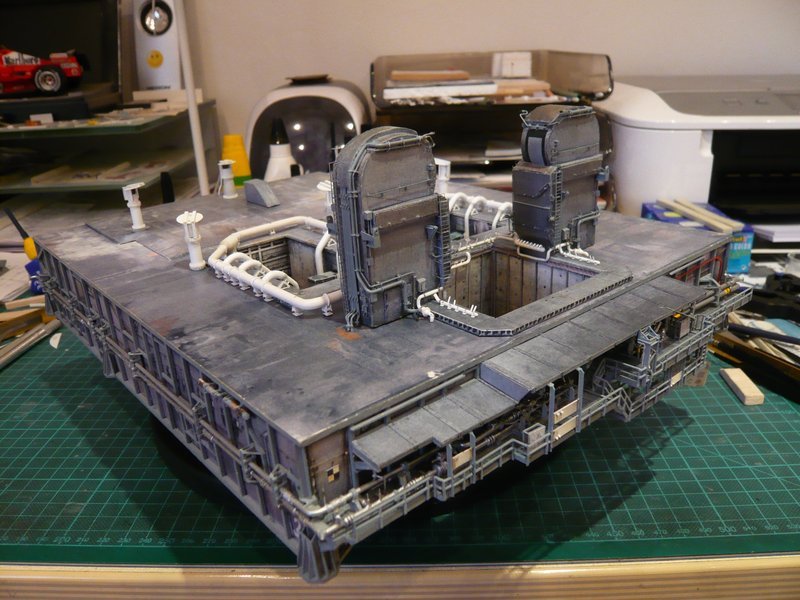

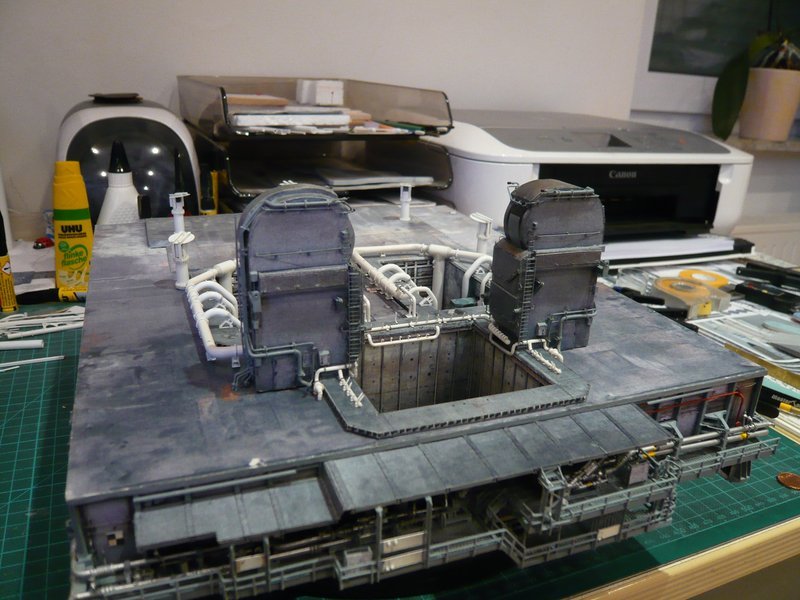

And so the MLP deck looks now from above.

After that, I went to the Stair Housing once more, with which I was not completely satisfied, especially since it was built in an early stage, in which I was still not as exacting and crazy for details as today.

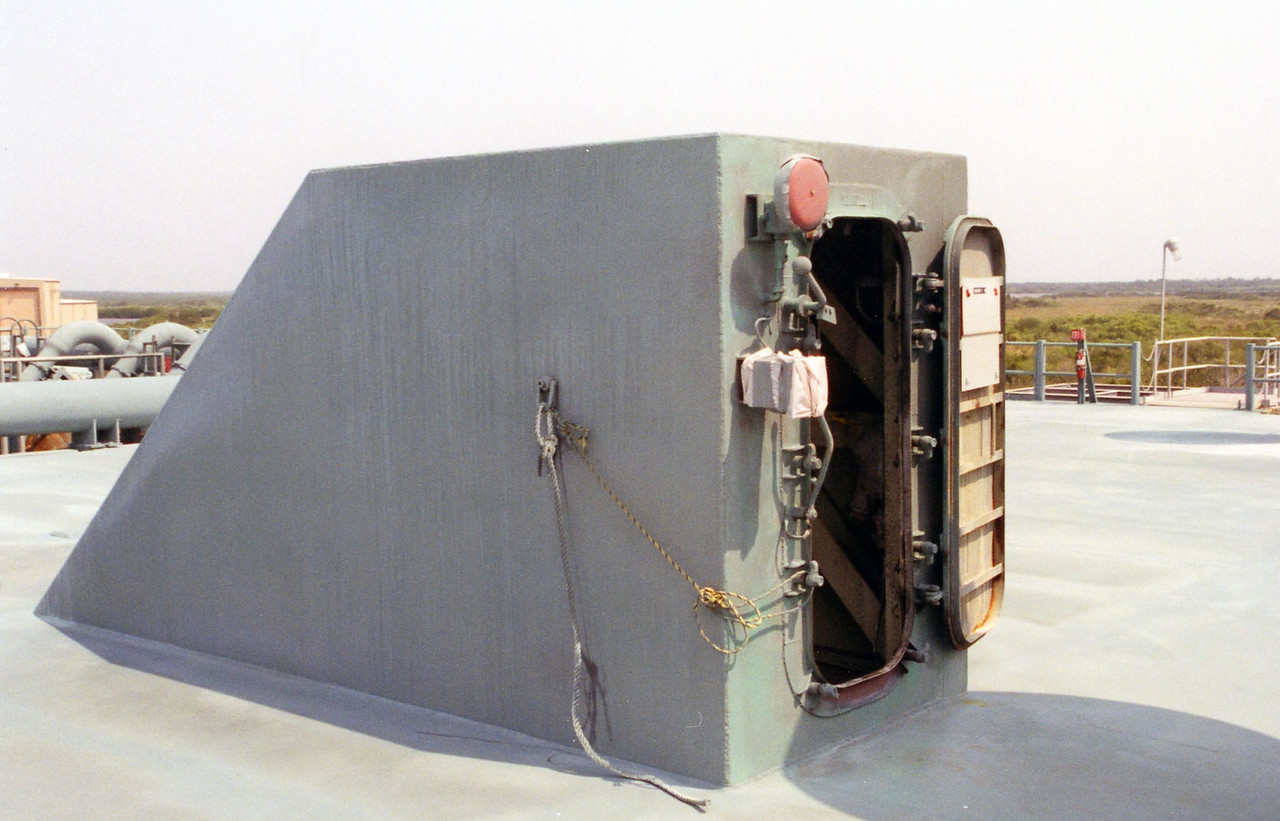

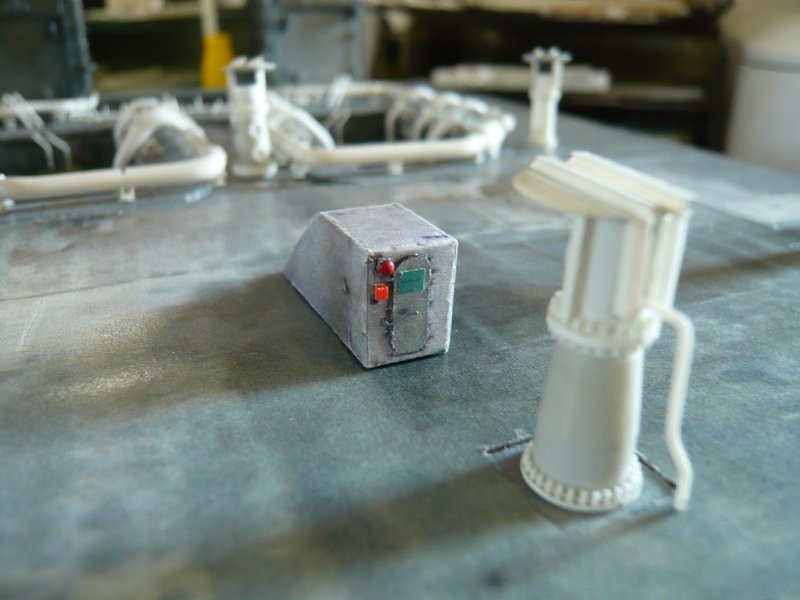

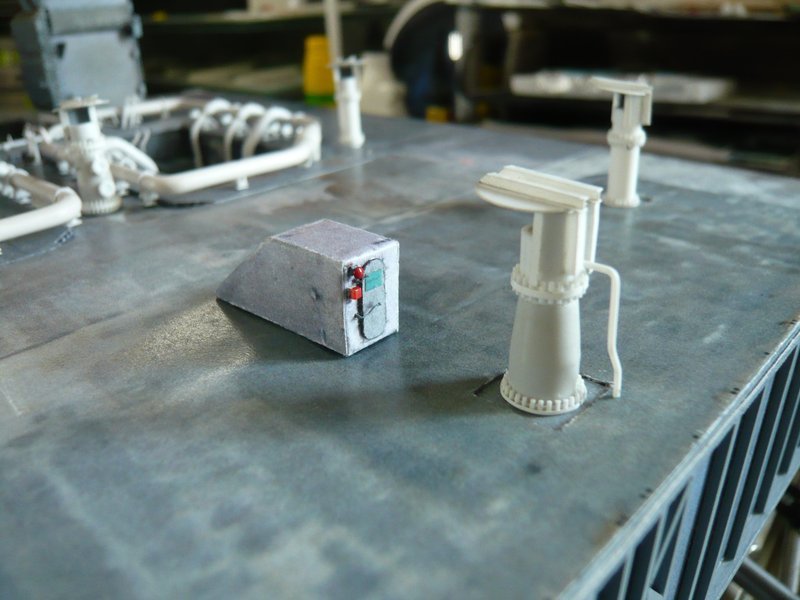

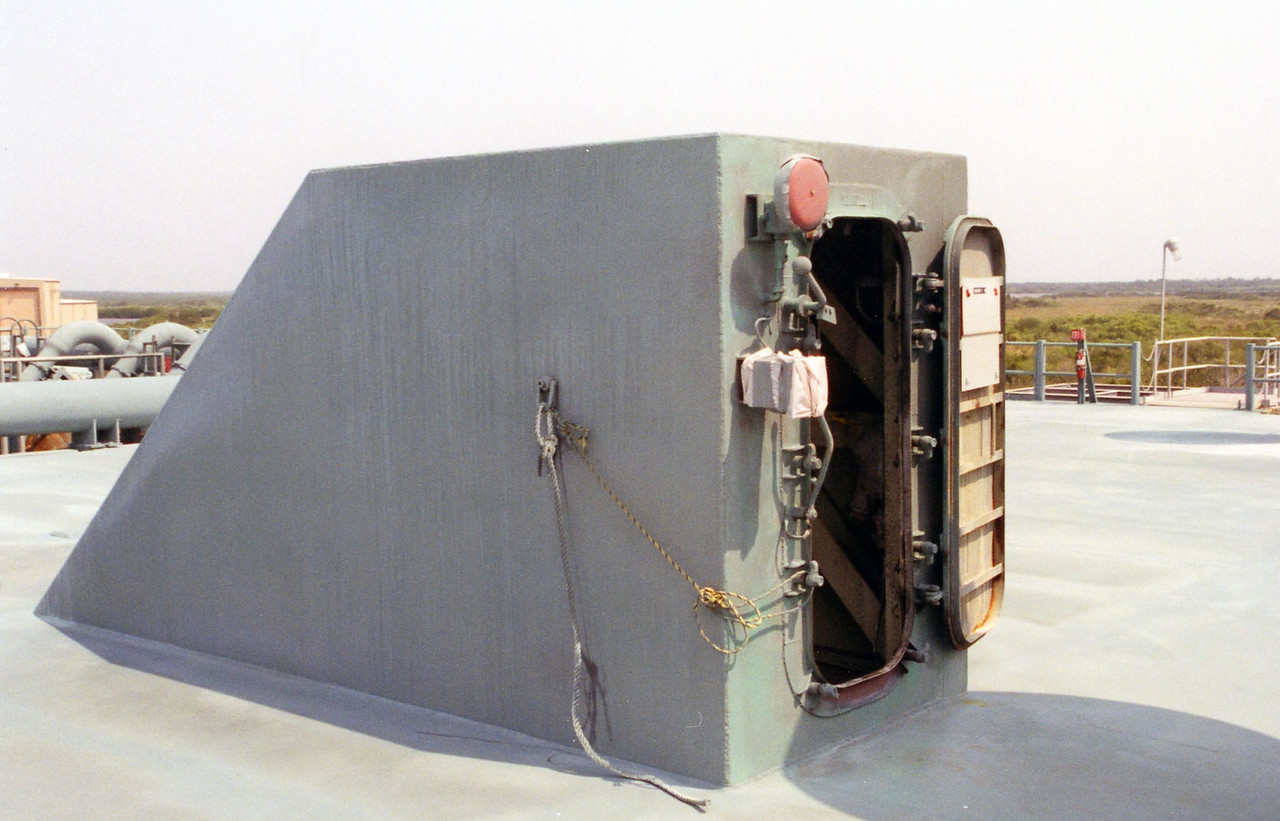

Since the housing from the Paper Kit especially at the back with the door looked relatively pale,

I had it at that time a bit weathered, which then but became a bit too dark. In addition, I had now found some detail photos, which have naturally animated me for scratching.

In this image one can see some details that seemed feasible to me, especially this red warning bell in the upper left corner.

Source: capcomespace.net

Here is a similar image from that time from the other side.

Source: apollosaturn.com (John Duncan)

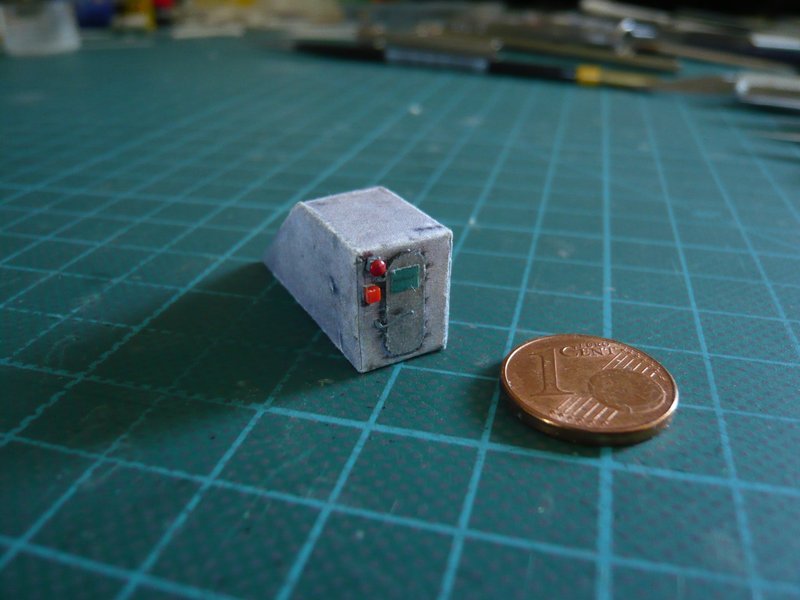

This is why I built the housing once again, and now I find that the coloring, except for the too bright door, it fits better into the picture than the old one, which in turn is pure taste.

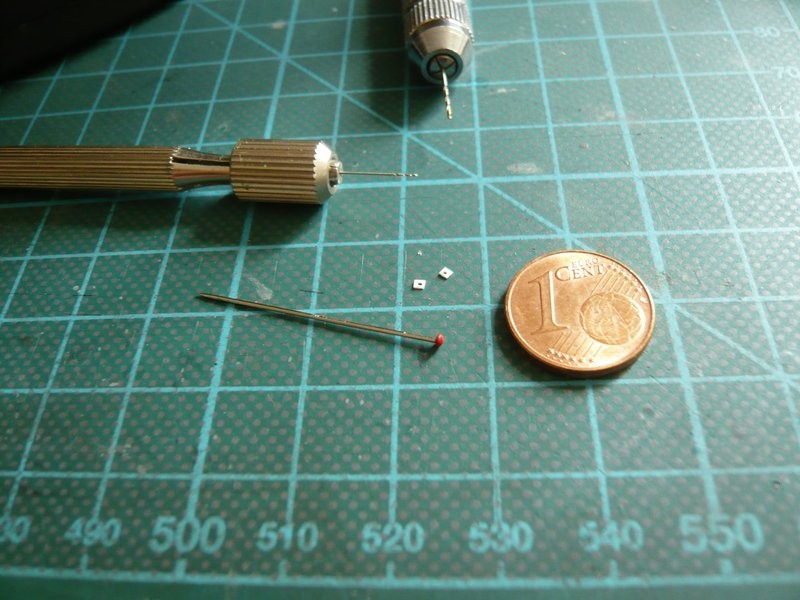

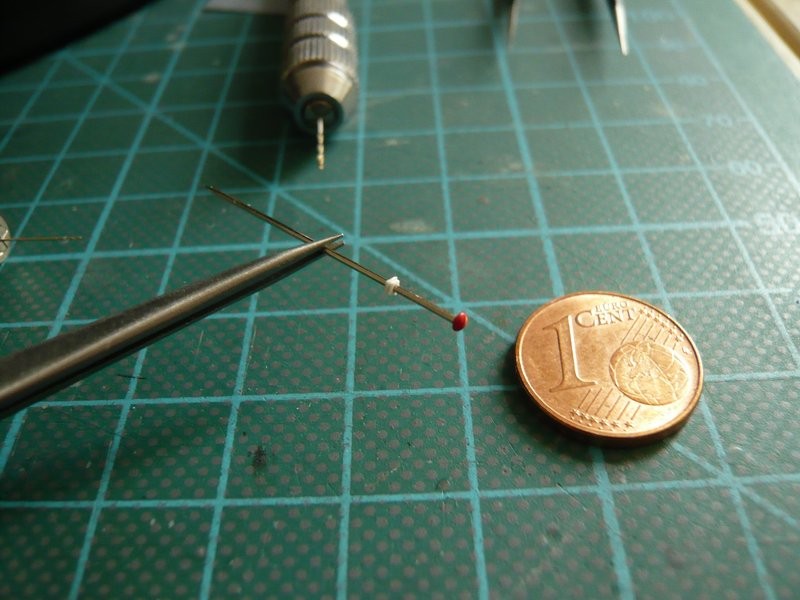

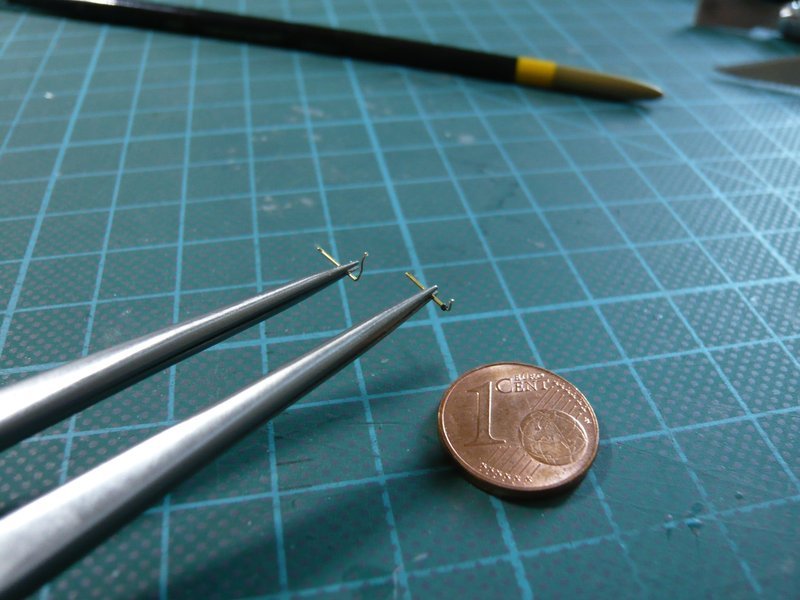

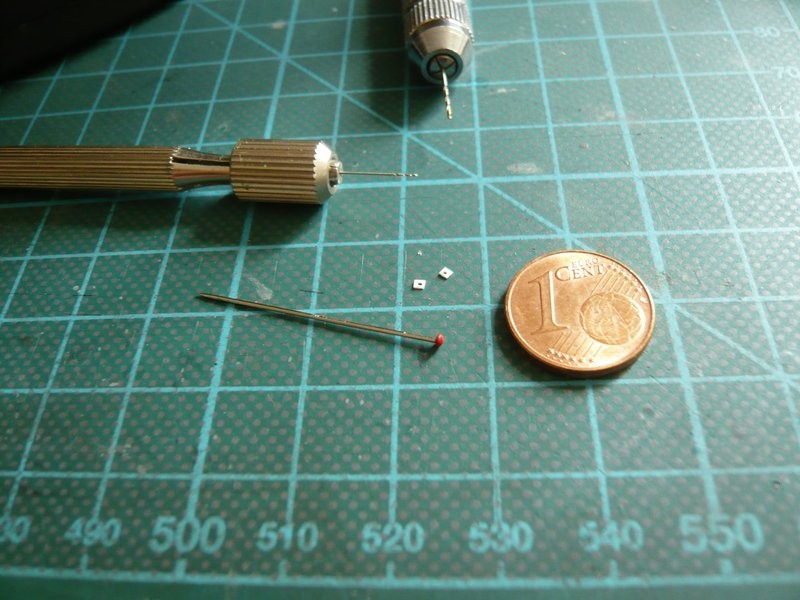

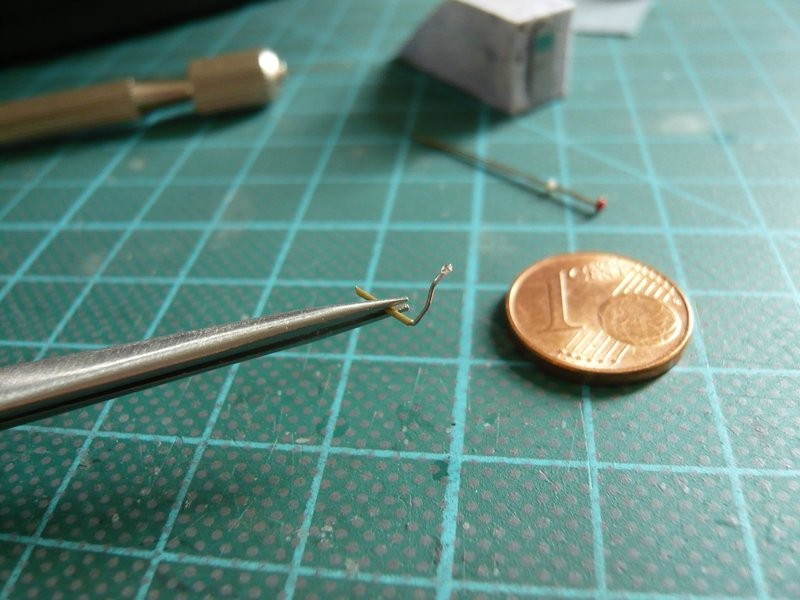

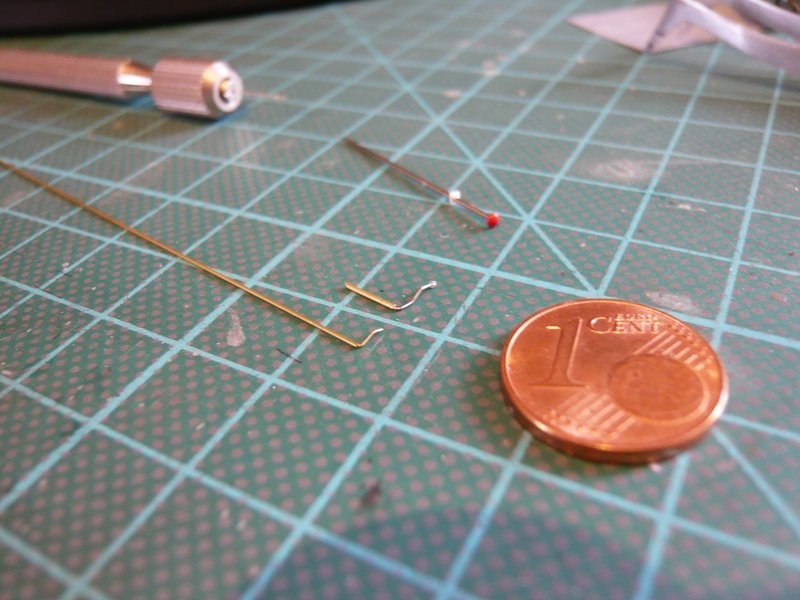

And now to the required small parts, e.g. this bell. At first, I had thought of small red discs, which I had punched out of the cap of a thumbtack, which should be about 1,4 mm in diameter.

Then, of course, there are also pin needles with correspondingly small, flat head, which I dipped briefly in red color, which looks almost even better.

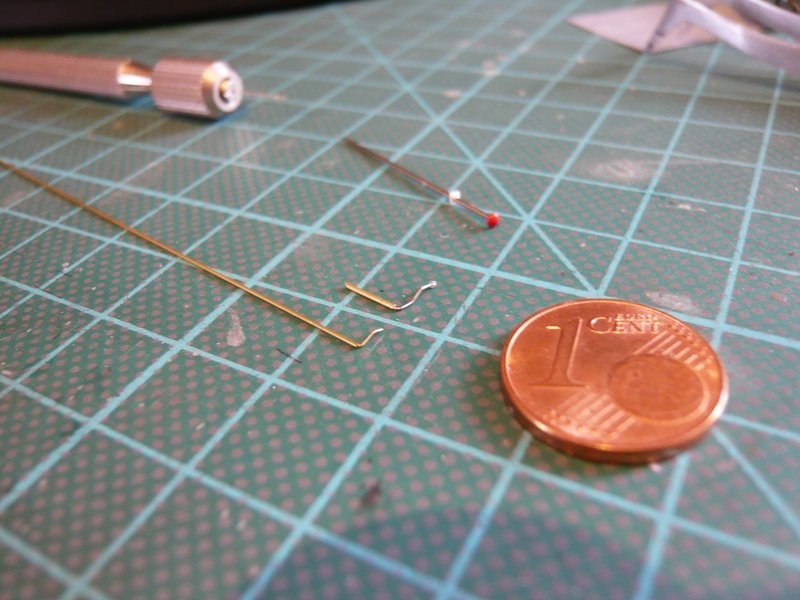

For the red box underneath the bell, I used the holder of an interdental brush, from which I have cut off one of these side pins, which correspond to the required size with 1 mm x 1 mm.

As one can see in the images, the bell sits on a small support or socket, which I still need to color.

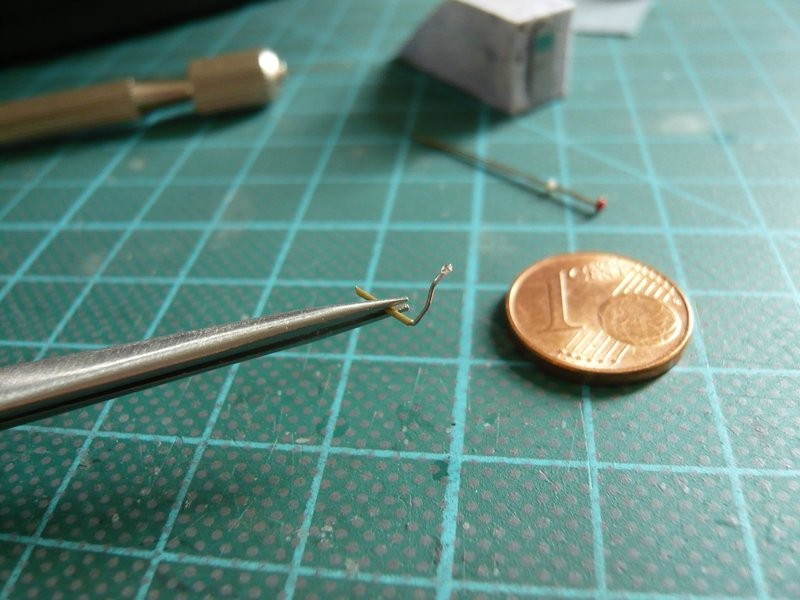

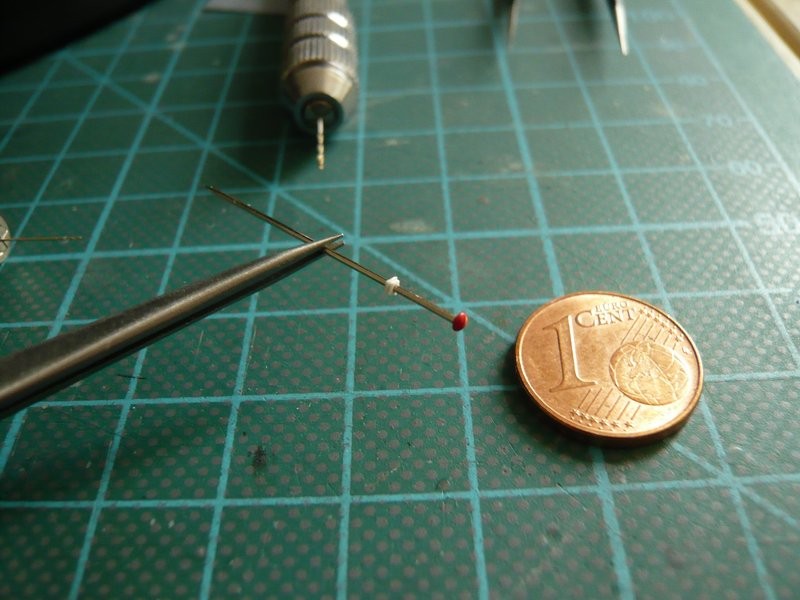

Then I tried the lower longer locking lever made of 0,3 mm steel wire, which is inserted in a brass pipe (0,4 mm) and could be rotated thereby. The ball handle is a glue drop, but it is still a bit too big.

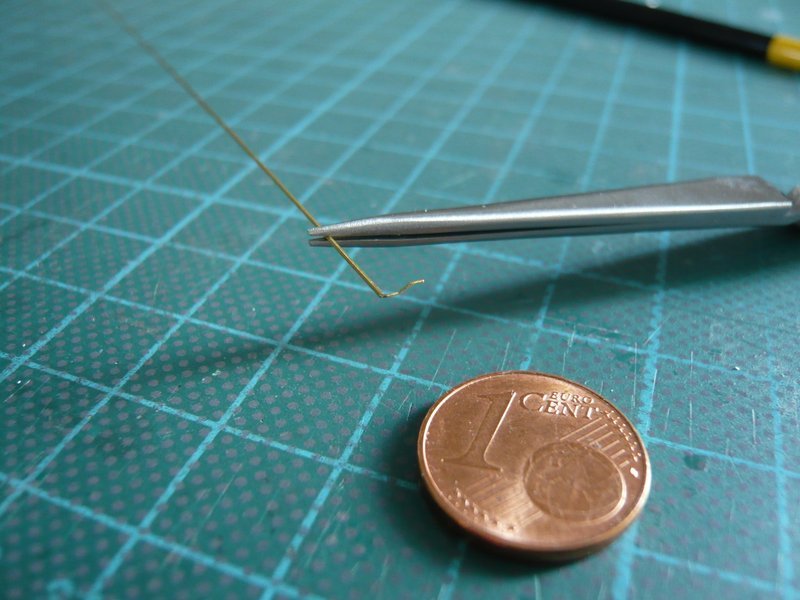

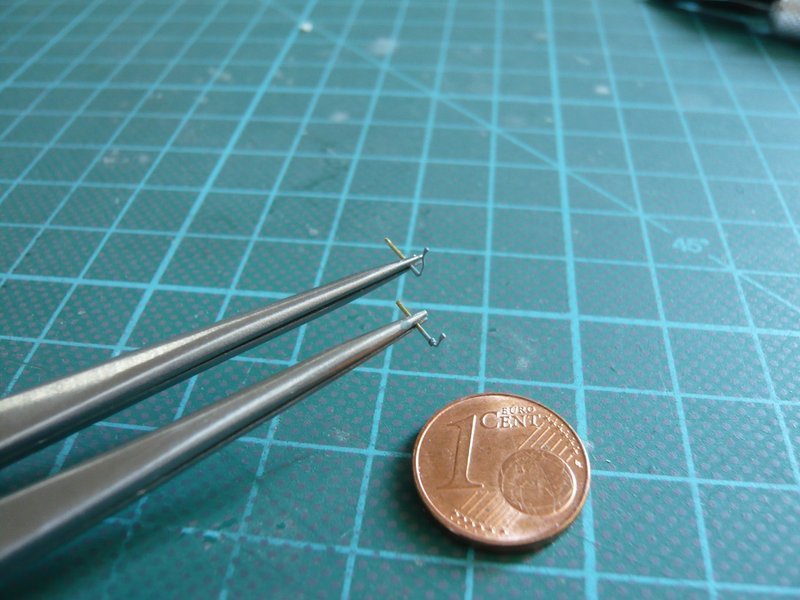

Since the lever seems to be too long and too thick on the housing, I have tried the whole thing again a little smaller and shorter, with brass wire 0,2 mm in a 0,3 mm brass tube, but still without a ball handle.

This could already look better and should be tried on later.

![]()

![]()

![]() or is there still something missing?

or is there still something missing? ![]()

![]()