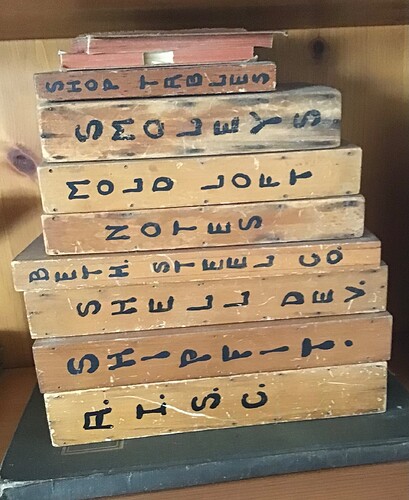

This is a monster project that I’ve been wanting to do for years. The market had to catch up to me with the issuing of an Iowa Class 16" turret. I just viewed a box review to see what was in the kit and get a quick fix on just what I would have to make from scratch. I’m sure someone, somewhere has done this before, but I’ve never seen it.

This is a screen print of what I saw.

Behind the blast bags is… nothing. That means the entire gun from the exposed part of the slide reward needs to be created along with everything else. My plan is to do the gun house interior completely including guns, gun rooms, control space with equipment, manual trainer’s and pointer’s stations, the big rangefinder, etc, down to the 2nd deck below; the electric deck. This is the rotating part of the turret.

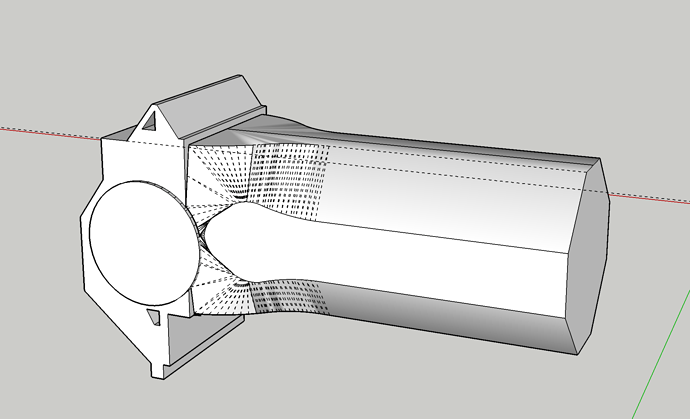

I already started, assuming correctly, that nothing would be in side. I started with the gun lugs, and am drawing the entire rear half of the guns. I am drawing all of this apparatus on SketchUp and then will 3D Print and scratch build all the rest.

Here’s the gun lugs.

Also, I will have to thicken all the walls with material to simulate the turret armor. I have pretty good references for all of this, but no actual dimensioned blue prints. The curator of the USS New Jersey Museum Ship sent me the actual dimensions of the rear face of the gun. With SketchUp if I can get one good measurement I can scale from that. So here’s the work on the breach end.

There are 20 threads in every segment of the step-thread breach. While I can make them and probably print them, I don’t know if you’ll see them in 1:72. It may not be worth effort.

This is going to be a massive project and will take a long time. I may not work on it continuously the whole time, but as many of you who’ve followed my other builds on this forum and other forums, I usually finish what I start.

While My initial plan is to build the gun house down to the electric deck that lies below, I’m not particularly interested in doing the projectile and powder flats, since there’s really nothing going on. The projectile and powder lifts follow a tricky path and might present distinct challenges.

The guns are traversed by two very large pinion gears driven by hydraulic servo motors onto a massive ring gear that runs around the barbette’s circumference. This ring lies well below the deck level. Riding above the ring is the roller track with a series of conical roller bearings that support the rotating structure and let it rotate smoothly with limited friction.

Additiionally, elevation is accomplished by a very long and robust roller screw that is raised and lowered by a hydraulic ball nut that surrounds it. It’s a very smooth, precise and sophisticated way to raise and lower the massive gun with little or no backlash. This compares to the pinion and sector that found on traditional artillery pieces.

All of this equipement is energized by hydraulic servo systems with and A-end pumps powered by electric motors, and the B-end hydraulic motors. These can be modeled reasonably in this scale.

Notice in the above that there were duplicate sets of manual pointing and training stations on both sides of the turret. It’s what accounted for the two little housings that project out of the foreward sides of the turret. There were many ways the turrets could be aimed and fired, starting with the main radar gun directors high up in the towers. These were redundant since either director could control all three turrets. Then there was the main range finders in each turret that could also control the other two if the main directors were out of commission. Finally there were these manual stations that could aim each gun old school. These ships were meant to fight and the redundancies made sure they could under battle conditoins. It must have been weird sitting way up in those little spaces while these monsters were roaring in the room next to yours. Also, the guns were operated by handwheels not much different than those that controlled the 40mm batteries. Imagine the mechanical advantage needed to rotate a 10" wheel and move a 2,500 ton structure.

Drawing continues. I finally figured out how to shape the slide casting (forgings?). It was hard to figure just what the shapes really were. With that done, I was able to get the basics of the back end roughed out. There’s still a bunch of finer details needed to get it just right. But the hard stuff on this major component is complete.

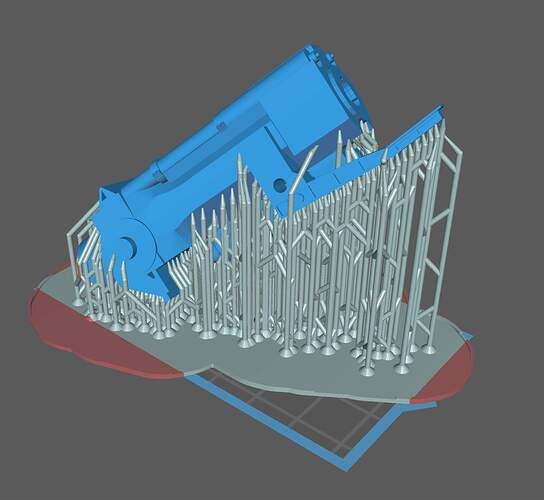

I fit the guns into the gun lugs on the turret that I drew. I don’t actually have to print the turret since it’s really the only thing that’s in the kit. But I wanted to get an idea if my scale was right. The guns dropped into the trunions perfectly so I’m comfortable with the widths. Remember: If it fits in the drawing, the printed parts will be exactly the same.

I elevated them to make the cutouts by interfacing the turret front face with the gun barrels in both depressed and 45 degree elevation and then cut out the marked areas.

I’m really looking forward to doing the detail work around the breach. Even though the gun house is in the Takom kit, I had to draw all of the gun house walls so I can fit all the apparatus into them. I’m actually going to model the rotating portion of the #1 turret. What’s going on below is also a major amount of work.

My printer is big enough to print the breach end from the trunion to the yoke as a single piece.

And now for some news: The curator of the USS New Jersey Museum Ship said they would display the model when it’s complete. He also granted my wish to see parts of the turret that are not open to the public for purposes of creating a better model. These would include the electric deck itself and those little manual control compartments that flank both turret side walls.

).

).

u

u