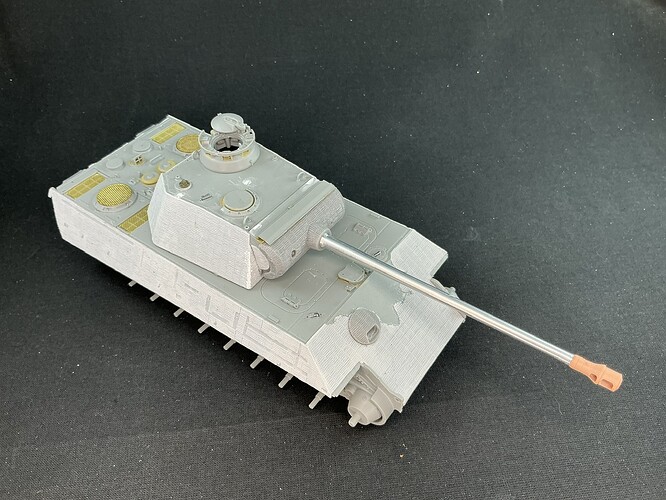

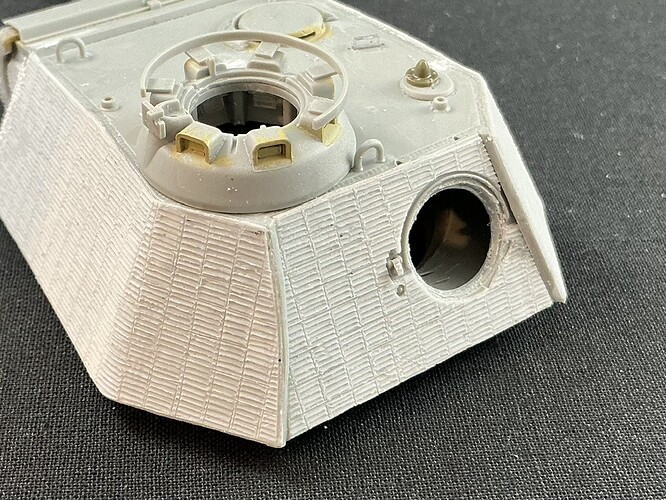

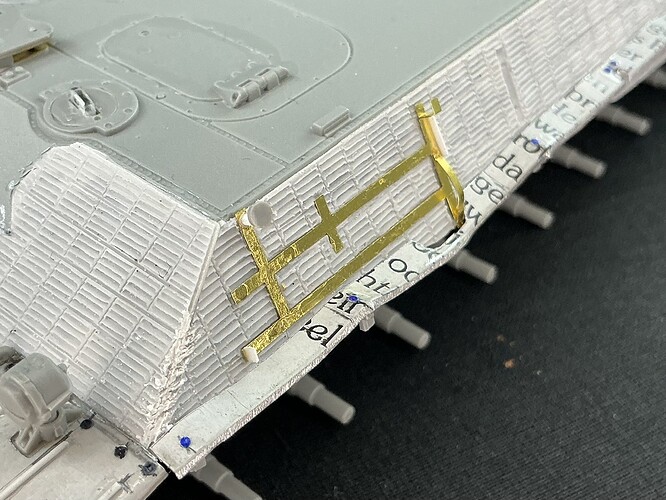

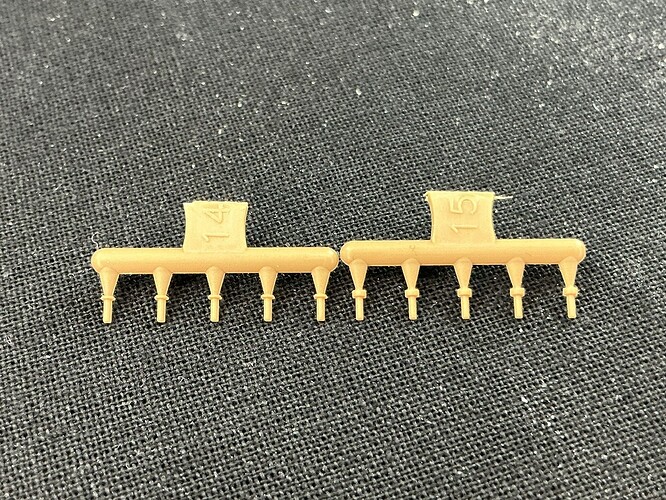

Tonight, I bit the bullet and finally started on the plates above the fixtures for the side skirts (which, of course, Cuckoo didn’t have).

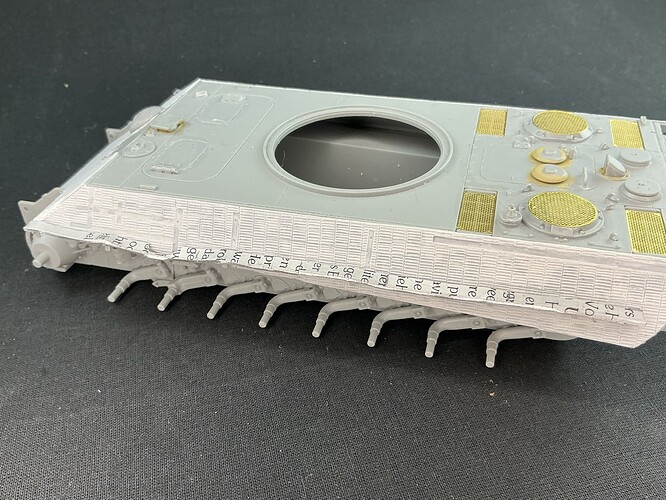

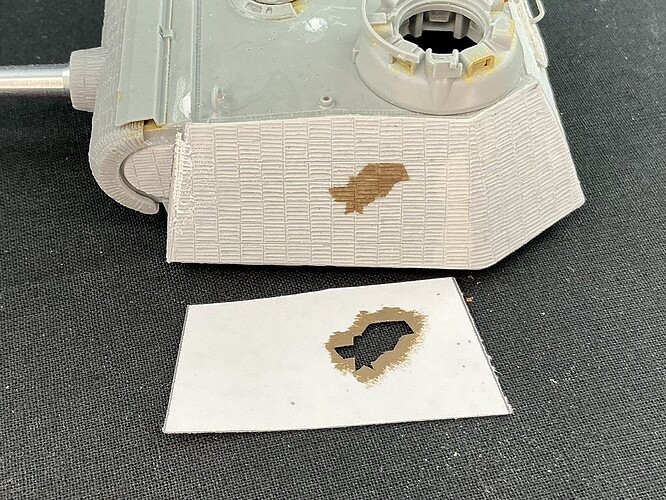

I took a piece of aluminium sheet and replicated one of the Dragon kit parts in it:

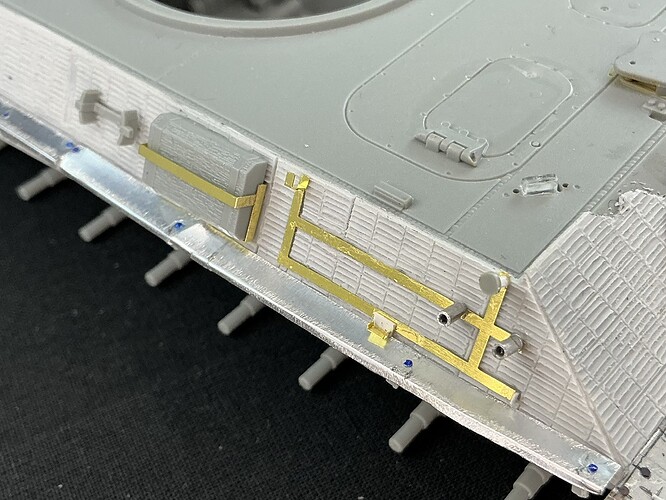

On the side skirt mounting bracket on the tank, that the strip will go on top of, I glues 0.5 mm square rod because the real ones are slightly taller, but Dragon’s plastic parts are thicker so they compensated by reducing the height of the mountings.

That’s one side, now the other  I’m not much of a metalworker, so for those readers who also aren’t, I’ll explain how I made these. First, I placed the kit parts on the aluminium sheet so that I could mark its length and width with the tip of my hobby knife, because that’s finer and therefore more precise than a pencil. I only marked the width at the ends, and not over the full length. Next, I cut through the plate over the whole width of the strip, to mark its full length. Don’t cut through in one go, but just like plastic card, make several shallow cuts until you get through.

I’m not much of a metalworker, so for those readers who also aren’t, I’ll explain how I made these. First, I placed the kit parts on the aluminium sheet so that I could mark its length and width with the tip of my hobby knife, because that’s finer and therefore more precise than a pencil. I only marked the width at the ends, and not over the full length. Next, I cut through the plate over the whole width of the strip, to mark its full length. Don’t cut through in one go, but just like plastic card, make several shallow cuts until you get through.

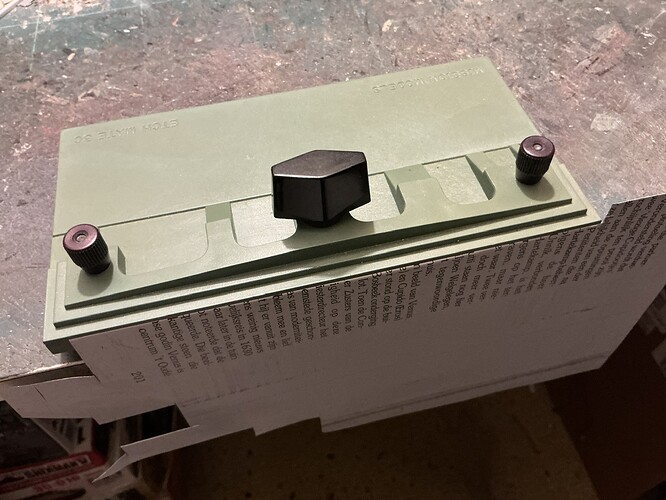

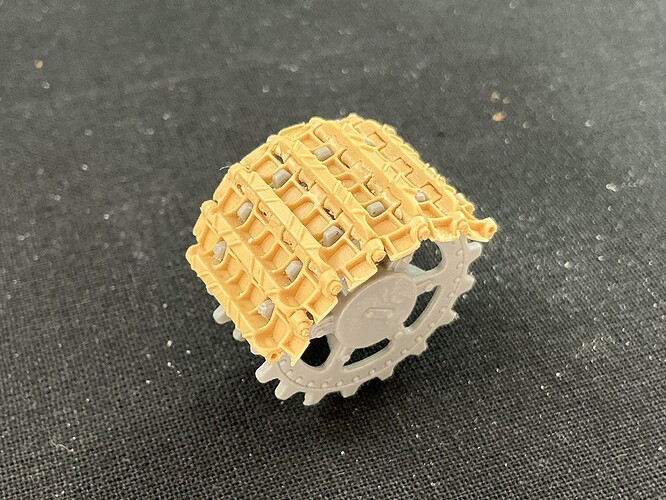

Then, I put the sheet into my Etch Mate, in such a way that the cut is just outside of the tool, and the lines I marked for the width were along the bend line:

Note here that the part that’s inside the Etch Mate is the piece of the sheet I need. Also, I’m using the back of the Etch Mate here, rather than its “surface”. I then put it on the edge of my work surface and placed a steel ruler over it:

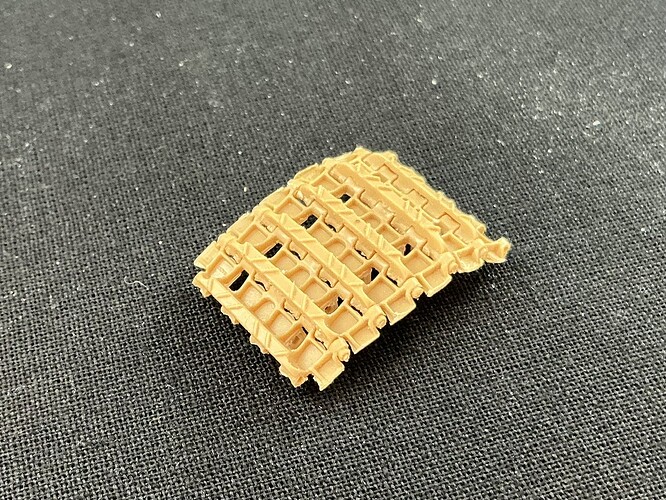

A careful but firm press down on it, rotating the ruler with the sheet (taking care to apply pressure equally), and we have:—

I nicely bent piece of aluminium sheet!

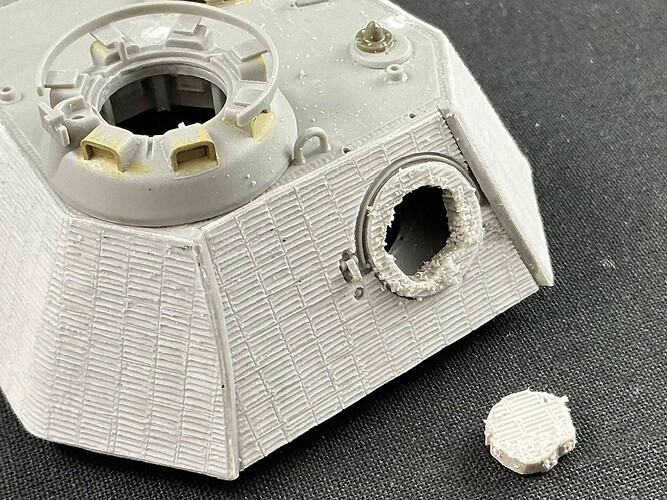

Problem number 2 was how to make a narrow, bent-down lip to it. I don’t have any photos of that due to a shortage of hands to take them with, but basically, I put the sheet onto the work surface, bent strip upward, and placed a thinner steel ruler “into” the bend — the ruler horizontally on the surface, but with its thin side rather than flat. That allowed me to run a knife along it, pressing the knife against the ruler while pressing against the upturned aluminium and the ruler with a finger of my other hand. That scratched a line into the aluminium, at a distance of just over the thickness of the ruler away from the bend. Now, don’t try to cut through the sheet, but wiggle the aluminium back and forth until metal fatigue causes it to break along the line.

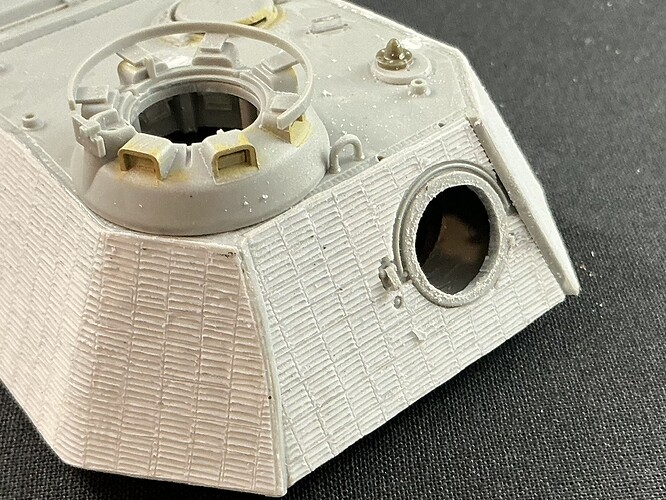

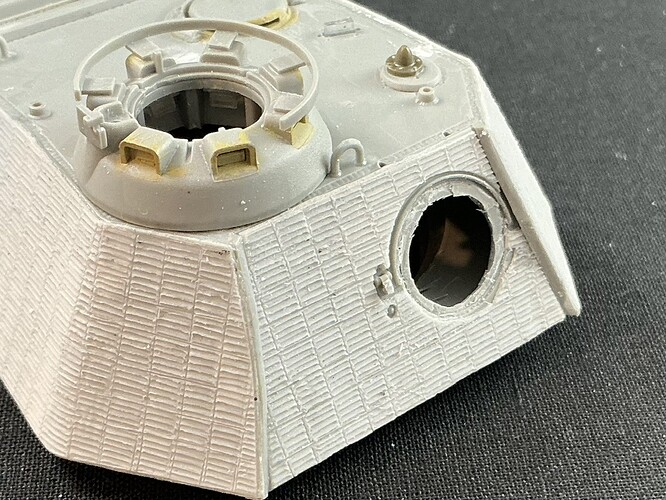

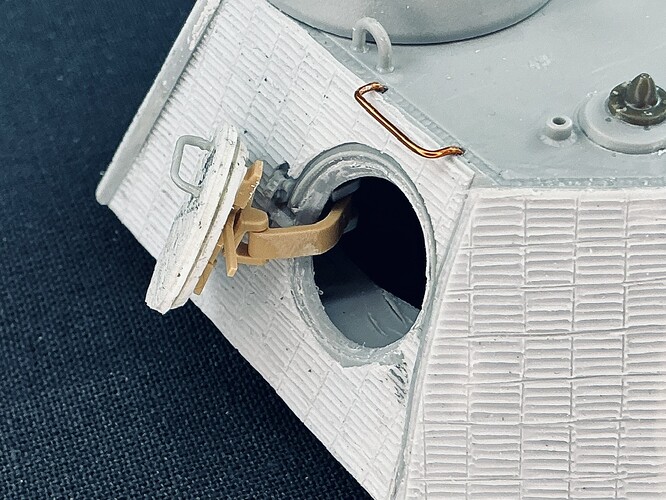

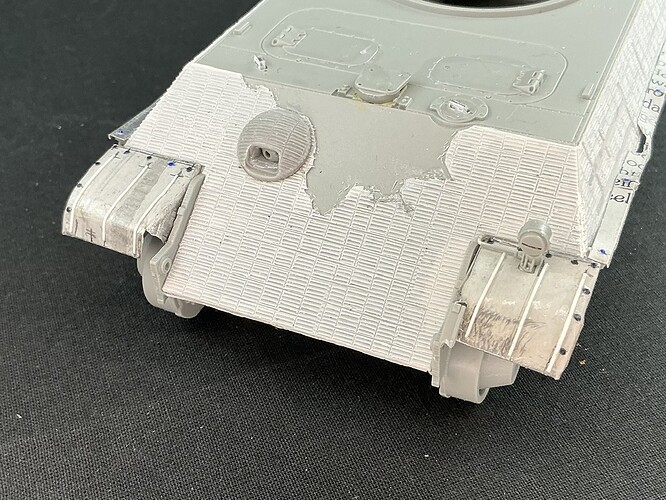

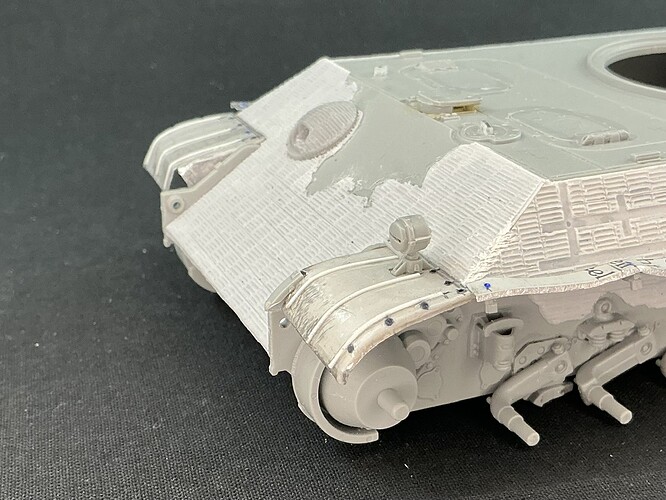

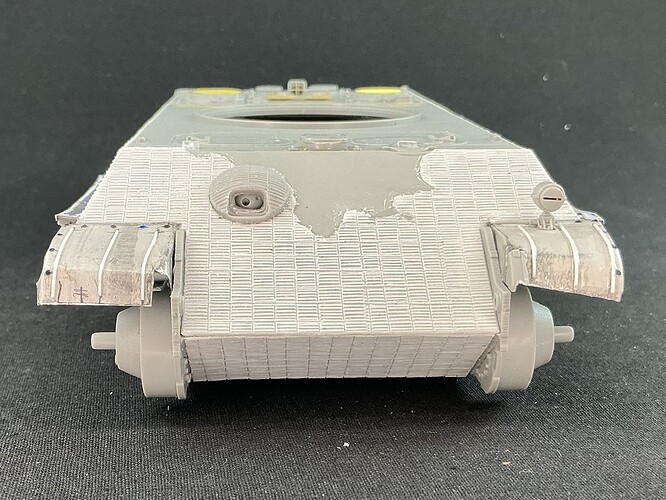

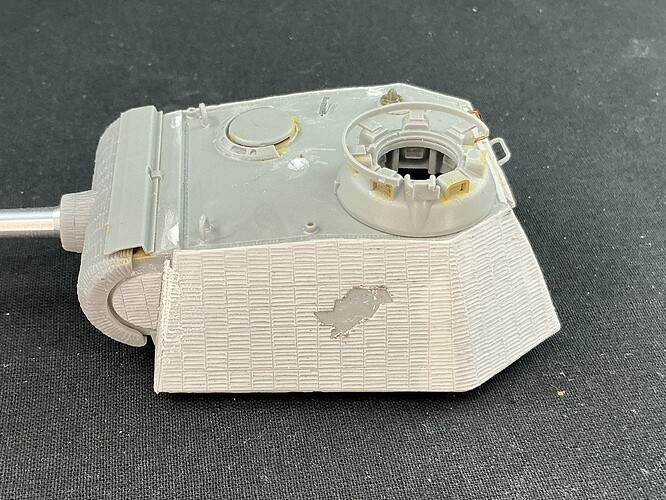

After some more work with a file to clean up the cuts, I could start fitting the strips to the tank, bending them to resemble those on the real thing, and then superglue them into place.

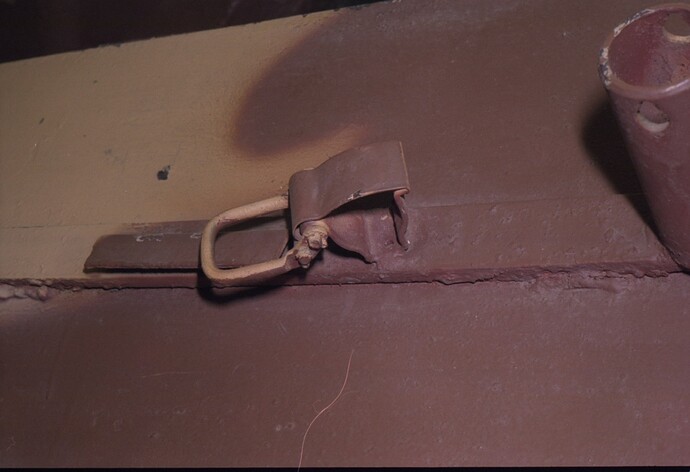

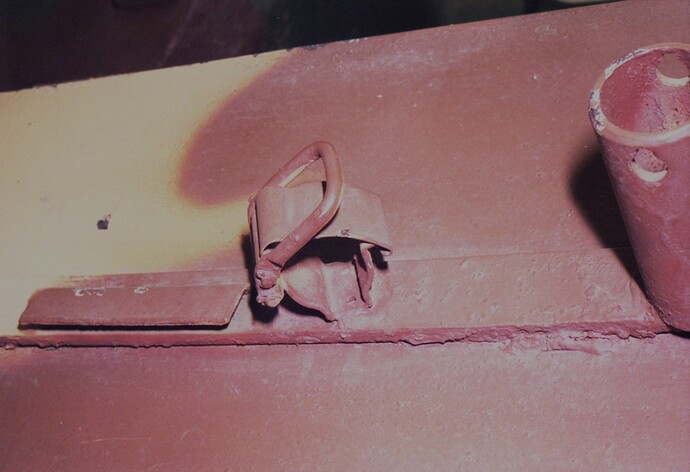

I looked closely at photos of the real Cuckoo for this and tried to replicate what I saw there. What I have is not 100% accurate, but I think it comes fairly close.

A side note to that: I was (almost certainly) going to paint this model in snow camouflage, but that’s a no go now. After I had made (but not yet distressed) the left-hand strip, I noticed that Cuckoo at the time of the film shot of it pushing down trees, is entirely missing the strip on the left. When it was photographed near Geijsteren and in Tilburg it still did, so my model will now represent it as it was there instead.